We take customer service seriously

Matt

Neither snow nor rain nor heat nor cold nights can stay our technicians from getting your line running perfectly so you can complete the work your customers demand. From the moment we begin a project, our field technicians and customer service department are on call for any help you need. From replacement parts, to troubleshooting, even onsite visits…if something is not going right, we are on call to get it back on track.

At Exeter Engineering, we like to think of our customers as friends and part of our family. And whenever friends or family have a problem, we’re there to help them out. Always. (Even if we forget to pack coats.)

Let's talk sweet potatoes in Texas

Matt

In a couple of days, Exeter Engineering is heading to this year’s Sweet Potato Convention at the Omni Hotel in Fort Worth, Texas. If you’ll be there too, we would love to talk to you about how we can help you sweet potato packing operations with super optical sorters like our multi-lane, multi-drop powerhouse AccuVision 360 or our robust and reliable AccuVision. Both feature ID Technology, our industry-leading AI-powered sorting system…perfect for your sweet potato needs.

Exeter Engineering has partnered with the sweet potato community for decades. We like to think of our customers as part of our family. If you’re heading to Fort Worth and are considering upgrading your sweet potato lines, stop by and learn what we can do to help. We would love to add you to the Exeter Engineering family of customers.

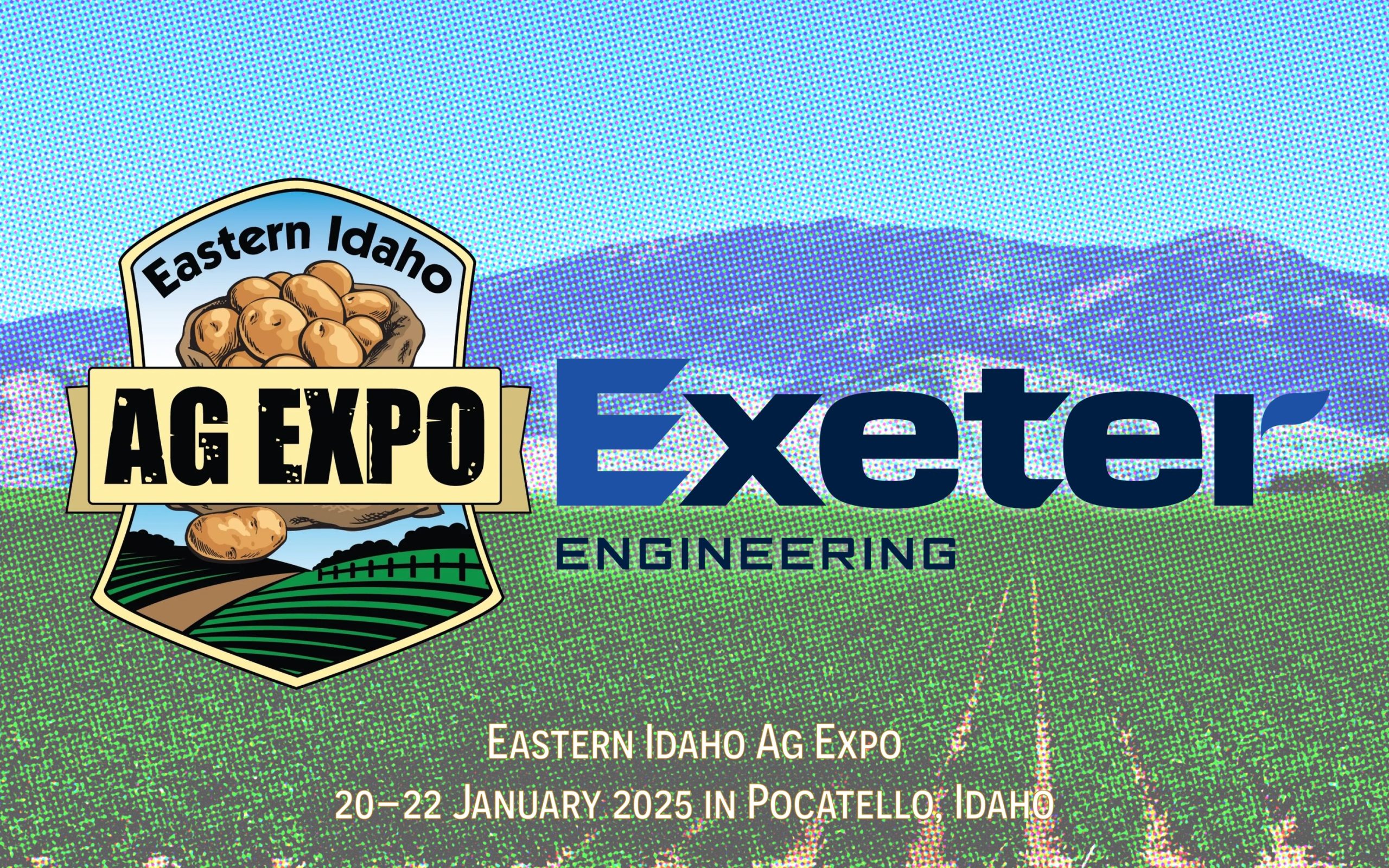

Join us in Pocatello for the Eastern Idaho Ag Expo

Matt

The Exeter Engineering team is heading back to this year’s Eastern Idaho Ag Expo in beautiful Pocatello. Stop by at booth 128 at the Holt Arena and say hello. We’ll be happy to show you an example of our Oculus compact sorter with ID Technology, Exeter’s industry-leading AI-powered sorting suite. The Oculus is just one way that Exeter helps our customers meet their potato challenges.

If you’re going to the show, we hope you’ll come on by and learn why some of Idaho’s largest producers are members of the Exeter Engineering family. See you next week!

ID Technology's UI is as powerful as it is easy to use

Matt

Exeter Engineering’s ID Technology is our industry-leading AI-powered sorting suite. A large part of what makes it so powerful is how easy to use it is for novices and experts alike — operators can learn how to sort like old pros in an hour or two. And there’s no need to have a miniature Death Star control room to run your sorting operations. ID Technology is so easy to use, you can leave it mounted next to your sorter or monitor it from a tablet and still be assured of the highest quality results. ID Technology’s fantastic UI also runs our Foreign Debris Detection and Hollow-Heart X-Ray systems. Learn one and you know them all, giving you even more capabilities to meet your goals and keep your customers happy.

See More and Sort Smarter with ID Technology and Exeter Engineering.

Happy New Year! It's going to be a good one!

Matt

The end of the year is often a time when people reflect on the past: what they’ve done, who they’ve seen, who they’ve lost and what might have been. And while those are worthy reflections, we are partial to looking forward to the year ahead and its exciting possibilities. Whether that’s a new customer, new improvements to our industry leading ID Technology AI-powered grading suite, or continued development of some of the finest optical sorters available anywhere, it’s truly an exciting time to be part of the Exeter Engineering family.

We hope your 2026 is filled with good stuff and fireworks. From our family to you and yours, Happy New Year!

Exeter Engineering at the Potato Expo in Dallas

Matt

Exeter Engineering will be heading to Dallas, Texas next week for this year’s Potato Expo. We will be bringing along one of our Oculus compact sorters, as well as our demonstration sorter that features a single lane Sidewinder and a single lane AccuVision RC, perfect for small or round potato varieties. All feature our industry-leading ID Technology AI-powered sorting and grading suite.

If you are going too, we’d love to see you! Stop by Booth 131, straight back from the Harvest Stage and say hello. We hope to see you there.

Merry Christmas to All!

Matt

We have a confession to make. ID Technology, our industry-leading AI-powered sorting and grading suite is powered by Santa’s elves.* It turns out that, like many delivery businesses, Santa too has turned to artificial intelligence make his logistics operations more “efficient”, leaving a fair number of the elves underemployed. Having benefited from their work on toys over the decades, and respecting their cleverness and ingenuity, we partnered with Santa to produce ID Technology. That explains ID Technology’s reliability, ease of use and also why it just seems like magic.

So, this Christmas season, as you enjoy the holidays with your family and friends, think also of the elves, toiling joyfully away in fresh produce facilities across the land, making ID Technology work perfectly to save you money, time and keep the grinches at bay.

Merry Christmas!

* The engineers and craftspeople who actually build ID Technology and make it work so well wanted to make sure that we acknowledged that, in fact, it was they who made ID Technology work so well and they who helped our customers with custom-datasets, constant upgrades and keeping everything ship-shape. They also hastened to add that, though it is not Santa’s elves powering ID Technology, they completely believe in Santa and respect the elves as engineers and craftspeople, and that they have been very good this year and not naughty at all.

The Sidewinder Goes Down Under

Matt

Back in the spring, we had a call from down in Australia. A well-known Australian mango packer — Deane Farms of Horseshoe Lagoon, Queensland — was looking for an optical sorting solution that would offer them speed and accuracy in optical grading without requiring weeks of staff training, lots of maintenance and at a reasonable price.

We proposed the Sidewinder.

After the machine was completed, we broke it all down and shipped it to Queensland. For the past few weeks, two of our top-notch field technicians (William and Gunnar) have assembled the machine, got it up and running and just finished some calibration sorts. You can see in these photos that the machine looks at home in its new locale and the Sidewinder is humming.

If you’re sorting mangoes…or avocados, bell peppers, cucumbers, small melons, onions or either hard or soft squashes…and need an upgrade to your lines that will save you time, reduce labor costs, improve productivity and give you an ROI in no time, take a look at the (now!) world-famous Sidewinder. With its unique rolling presentation and tight links with our industry-leading ID Technology, you’ll see more and sort smarter…which is enough to make anyone’s day a g’day indeed.

Prepping for the PMA show

Matt

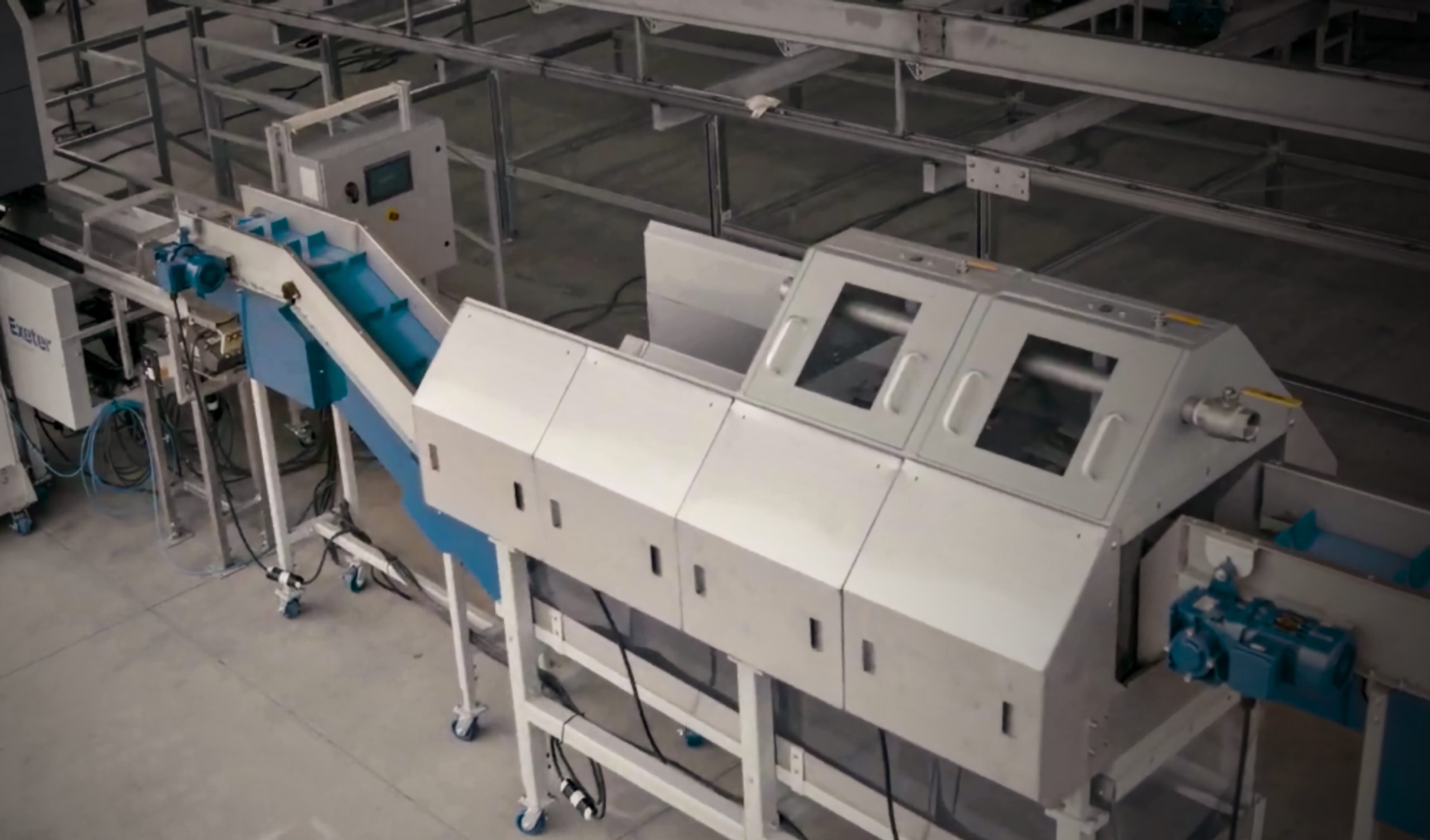

We are making final preparations for the Produce Marketing Association’s annual Global Produce & Floral show, coming up next week (17-18 October) in Anaheim, California. We have built a hybrid optical sorter to demonstrate two of our different sorter types to the folks at this year’s show. This machine sports two lanes. One runs our Sidewinder sorter’s presentation system, featuring a spinning action that rotates product as it passes beneath the camera box — perfect for a number of produce types, including hard and soft squashes, mangoes, avocados, etc. The second lane runs our AccuVision RC’s roll carrier presentation system, which is designed for round produce like onions, small or round potato varieties, as well as bell peppers and the like.

We built this machine to allow folks to see how these two types of optical sorters operate and how well they integrate with our industry-leading ID Technology AI-powered grading suite. The tight integration of the presentation system with our high-definition cameras and specially-tuned LED lighting yields fantastically clear imagery. The ID Technology grading software uses that imagery to make near instant decisions on which drop to send each piece of product in the sort. It’s easy-to-learn and easy-to-use user interface gives operators instant feedback, live images and real-time statistical analysis to show operators what the results of a change in sorting parameters will mean for the rest of the sort. It’s so easy to use, you’ll be running each sort like an expert after an hour or two.

If you’re heading to the PMA’s show, please stop by booth 3011 at the Anaheim Convention Center. We’ll be happy to show you this machine in action and demonstrate just how ID Technology can help you see more and sort smarter.

Hope to see you there!

Exeter Engineering is heading to the Global Produce & Floral Show

Matt

Exeter Engineering is so pleased to be heading to this year’s Global Produce and Floral Show in Anaheim, California. We will be with the good folks from the International Produce Marketing Association at the Anaheim Convention Center on 17-18 October, booth 3011.

For this year’s show, we’ve built a demonstration machine that has one lane running our Sidewinder’s carrier — with its unique spinning presentation — and one lane running our AccuVision RC’s roll carrier design — perfect for onions, tomatoes or round and small potatoes. Between them, those two sorters will grade and sort anything from hard and soft squashes, bell peppers, avocados, cucumbers, onions, melons, onions, tomatoes or small or round potatoes. Both feature our industry leading ID Technology AI-powered grading suite, offering unparalleled accuracy and efficiency.

Come by and take a look at this hybrid machine and see just how well each carrier could work for your product, how well they work with ID Technology…and how that combination will save you time and money. We look forward to seeing everybody in Anaheim! #GPFS2025

Guacamole? Guacamole. Guacamole!!!

Matt

At Exeter Engineering, we always say that our favorite meals is…anything that has guacamole. 😎 That’s why we are so happy to celebrate National Guacamole Day today. For years, we’ve partnered with avocado producers to help them get their best avocados from the orchard to your table. That’s why our industry-leading ID Technology, AI-powered optical grading suite is so popular with avocado growers and packers. It helps them quickly, accurately, and gently sort their avocado crops. Available on all of sorters, it takes advantage of the tight integration between presentation, cameras and lighting and our top-drawer user interface to help avocado folks maximize profit and minimize the time between avocado and guacamole.

Celebrate National Avocado Day with your favorite recipe. And if you’re in the avocado game, get in touch to learn more about how Exeter Engineering can help your business. You won’t regret either!

Exeter Engineering's optical sorters are an investment for life

Matt

Exeter Engineering has got your back. We’ve been engineering and building optical sorters to last since 1988. And with our AccuVision Upgrade program, even older sorters can have the latest technology. We recently completed an upgrade for our friends at Desert Ridge Premium Produce in Moses Lake, Washington. We upgrade a 15+ year-old AccuVision 4-lane sorter with new tracks and electrics. We also added ID Technology, our AI-powered grading suite, including upgraded cameras, lighting and software. While we were at it, we replaced an old sorter no longer supported by its manufacturer, installing a new 6-lane AccuVision with ID Technology as well.

Desert Ridge wanted higher capacity and more accuracy, and we delivered. They got two “new” sorters for a lot less than our competitors would charge, all if the same footprint as the old equipment and both running our industry-leading ID Technology, with the best UI on the market today. We were proud that the old AccuVision still has more to deliver and happy that the new one will delivering for decades to come. We know that because, with Exeter Engineering, you can be guaranteed that we won’t leave you behind, no matter how old your equipment gets.

A heartfelt thank you...

Matt

Exeter Engineering is a family owned and operated business. Unfortunately for us, occasionally some of our family members retire and go on to pastures new. That’s happened twice to us this year, with the retirements of Liz Rowland, who retired in July, and Debbie Shultze, who retired in April. If you’ve ever had the pleasure of visiting our facility in Exeter, then you’ve probably had the pleasure of meeting one or both of Liz and Debbie. Both were key parts of our front office, keeping things humming along even if all descended to chaos around them. It’s people like Liz and Debbie who make Exeter Engineering such a special place to work. Their tireless support and good humor made it easy for our team, the rest of the Exeter Engineering family, to concentrate on engineering and building some of the finest equipment for fresh produce handling available on the market today. We all enjoyed Liz’s retirement party recently, but we wanted to take a moment to publicly thank both she and Debbie for all of their work and dedication over the years. Thanks ladies…and enjoy retirement!

A Day to Celebrate Potatoes

Matt

This little guy is happy for a reason. He was born and raised in a potato patch tended by a farmer who lavished him with water and nutrients that allowed him to grow big and delicious. He was harvested with the greatest of care, so that his tender flavor would be preserved. As he went through the packing house, he was gently cleaned, dried and reviewed by Exeter Engineering’s ID Technology AI-powered optical grading suite to make sure that he was up to snuff. Having passed muster, he was packed with speed and attention by Exeter Engineering’s precision equipment, all to arrive on your table fresh and delicious.

A happy potato is a delicious potato. So on this National Potato Day (or any day, really), we hope you enjoy the miracle of nature that is the humble tuber. We’re confident they’ll put a smile on your face too.

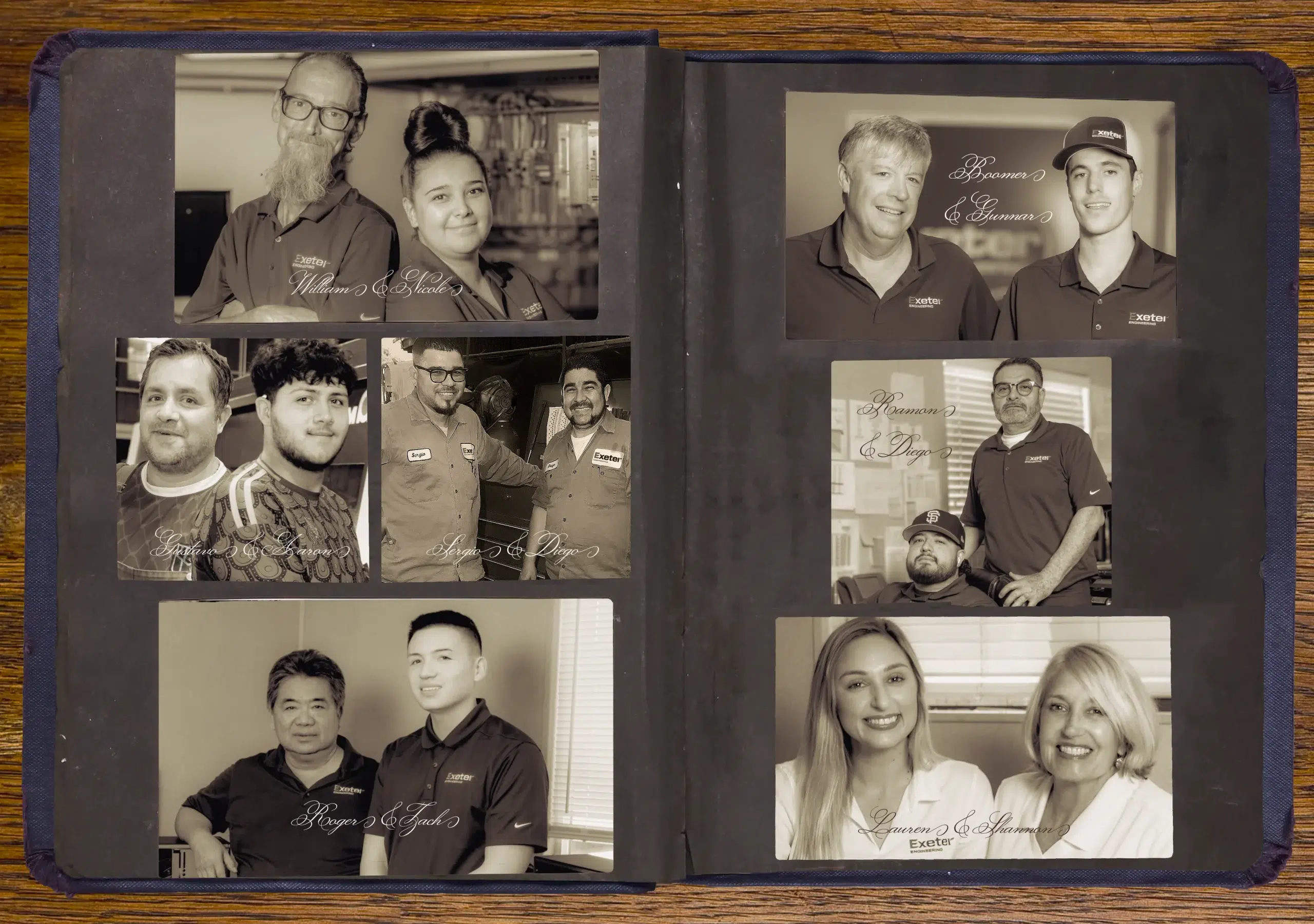

Exeter Engineering is family owned and operated...

Matt

Exeter Engineering has been family owned and operated since day one. But what does that mean to us? To our customers? Glad you asked! To us, being family-owned and operated means that we are a family business. Our reputation is not just the reputation of Exeter Engineering,

but of all the families that work with here. It means that, when we commit to designing you the best line available for your budget in your location, we will stand behind our work 1000% and will not rest until every aspect of the design, equipment and its operation is exactly right. Because if we don’t, you’ll know who failed and so will we.

Over the next few months, we’ll be taking a bit of time to introduce the families that make up the Exeter Engineering family. We’ll start with with Boomer and Gunnar Batchman. Boomer is our President and started working here in 1988. Boomer took over for his father, our founder Jeff Batchman.

Gunnar is the third generation of Batchman to work at Exeter Engineering and is currently a field service technician. Both Boomer and Gunnar share a love for the outdoors and enjoy time spent in the mountains, fields, streams and waters of the world, hunting, fishing, sailing and walking. They also love helping out our customers and have known many of them for generations as well.

We at Exeter Engineering know that there’s nothing like family to pick you up and keep you going, and there’s no other company like Exeter Engineering in today’s market. If you’ve got a fresh produce-related project that needs expertise and a family touch, get in touch! We’d love for you to join our family of customers.

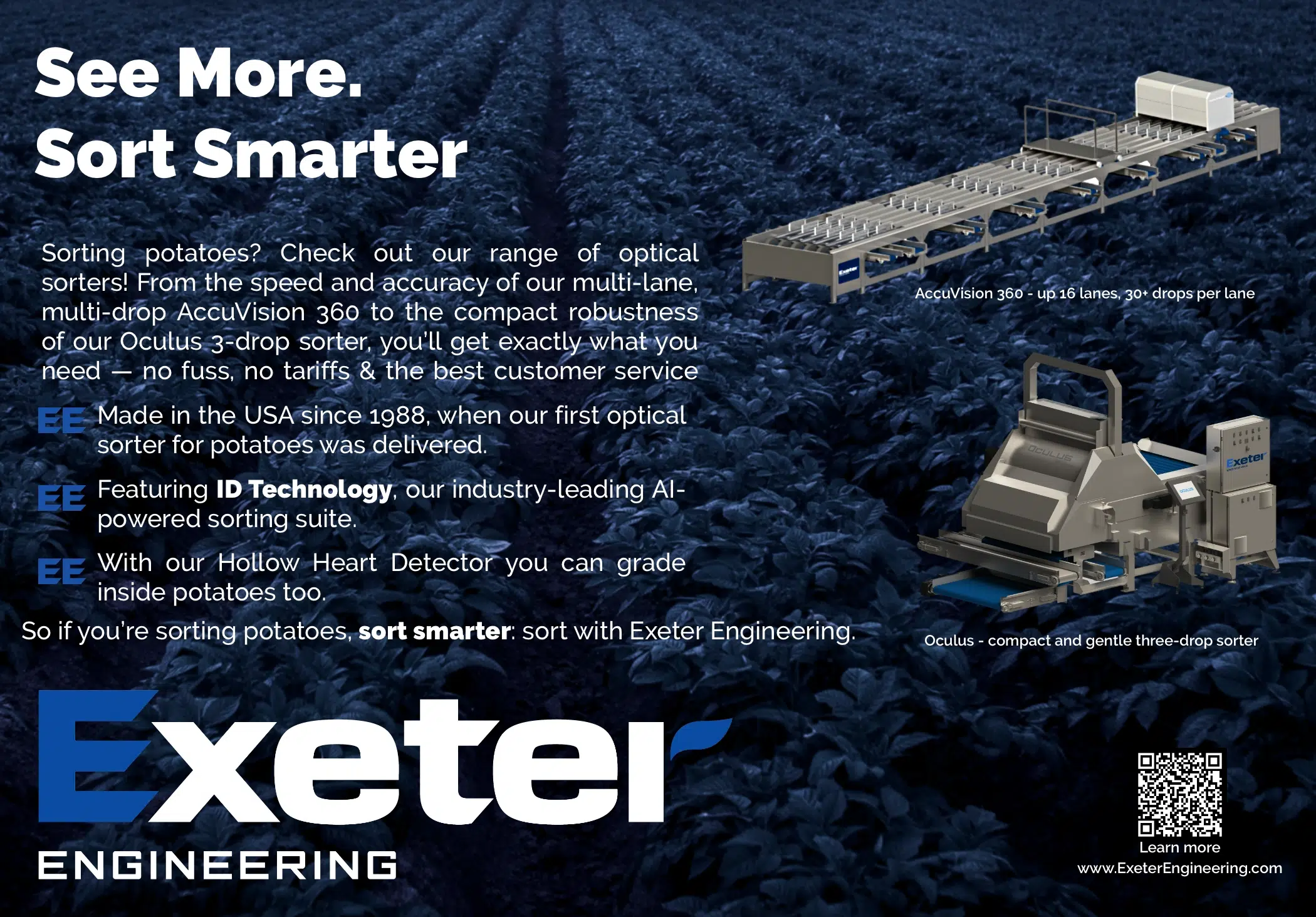

See More, Sort Smarter with Exeter Engineering

Matt

Exeter Engineering is a sorting company. We pioneered optical sorting, installing our first sorter in 1988. We’ve been at the cutting edge of technology ever since, providing reliable, well-engineered solutions for the fresh produce industry.

Today, our flagship optical sorters — AccuVision 360, AccuVision, Sidewinder and Oculus — all benefit from our industry-leading AI-powered sorting suite: ID Technology. ID Technology offers the tightest integration between presentation and imaging on the market today: we build our sorters so that our cameras capture the best possible images of each piece of product Combine those superior images with ID Technology’s easy-to-use, easy-to-learn user interface and you can See More, Sort Smarter.

If you’re looking for an optical sorting solution for your fresh produce crops, take a look at Exeter Engineering’s sorting options and get in touch. You’ll See More, Sort Smarter too!

Happy National Avocado Day!

Matt

There are a lot of ways to enjoy and avocado. We are partial to guacamole, but we know people who enjoy them cut into salads, mashed on toast, or even in a smoothie. Just as there are lots of ways to eat avocados, there are plenty of ways to get avocados from their orchards to your table. Farmers and fresh produce folks will tell you that getting those avocados to you safely, with no damage and with superior taste is no easy feat. That’s why so many avocado people turn to us for help. At Exeter Engineering, we make the equipment that makes your guacamole (or avocado toast, or smoothie, etc.) possible. That’s why we are happy to celebrate National Avocado Day and thank our friends and customers for all of their hard work. Cheers to them!

There's a reason Exeter is in our name too

Matt

Founded in 1978 in small-town Exeter, California, we’ve been part of our community for nearly 50 years. We’ve built some of the best optical and AI-powered grading systems on the market, shipping them worldwide—but California’s Central Valley is still home. We recently celebrated at Valley Strong Ballpark for Exeter Engineering Night at the Visalia Rawhide™. Baseball, hotdogs, and good friends—it was the perfect reminder of our community’s strength, which mirrors our company’s vitality. We like to say that there’s a reason “Engineering” is in our name, but “Exeter” is there too. Together, they capture who we are and what we do.

Got a fresh-produce project that needs help? We’d love to have you join our community of friends and customers. Until then, hope you’re having a great summer.

Happy Birthday America

Matt

Like the birthday girl, we are a proud, independent, family-owned company. And like our great nation, we are looking forward to gathering with family and friends to celebrate America’s birthday with America’s bounty. Happy 4th of July everybody, and happy birthday America.

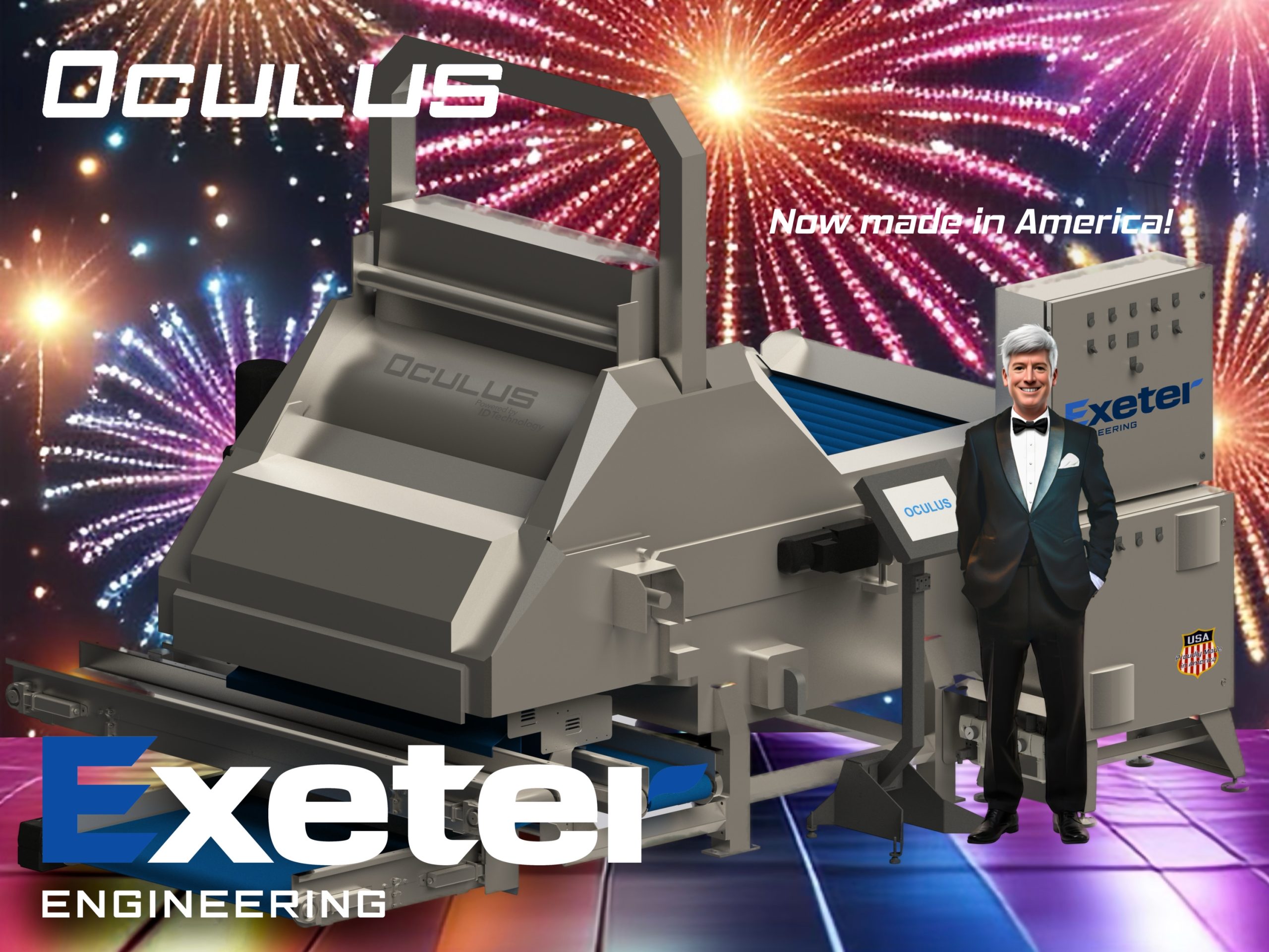

Oculus - the best compact potato sorter - now made in the USA

Matt

This Fourth of July, we are celebrating the independence of our country and the people who built, maintain and protect the things that make it such a wonderful place to live. We hope you and yours enjoy a great holiday as well.

We are also celebrating the Oculus, our compact, three-drop sorter featuring ID Technology…now made in the USA! The Oculus uses a unique rolling presentation system to maximize image quality for grading with our ID Technology system, Exeter Engineering’s industry-leading AI-powered grading suite. It’s also a rugged, easy-to-maintain sorter, perfect for sorting any variety of potato, clean or direct from the fields.

Now that the Oculus is made in the USA, it’s not subject to any of the tariffs or fees of competing compact sorters. If you’re in the market for a compact optical sorter for your potato crops, celebrate Independence Day and celebrate American-made. And get in touch if you’re in the market for the best compact potato sorter available today…

It's National Onion Day!

Matt

Consider the mighty onion. A must in many delicious dishes, it can also bring grown men to tears. It is truly a wonder of nature’s bounty. At Exeter Engineering, we’ve worked hard to develop our ID Technology AI-powered optical grading suite to recognize and preserve the highest quality onions so that you can enjoy their myriad charms morning, noon and night. We know that the folks who grow and pack these delicious veggies are proud of what they produce and we are happy to help them get the best to your table. So to all of you and all them, we wish you a Happy National Onion Day. Please pass the onion rings!

Wishing You A Wonderful World Cucumber Day

Matt

Today is World Cucumber Day. At Exeter Engineering, we are proud to partner with farmers and packers to bring you the freshest, most delicious cucumbers available. Indeed, without our Sidewinder optical sorters with their ID Technology (that’s our exclusive AI-powered optical grading suite), your cucumbers might be a bit less fresh and delicious.

So, whether your partial to a cucumber in your G&T, fancy a bit of tzatziki or some raita, or just like a pleasing crunch in your salad, remember to enjoy a cucumber today. And next time you see Boomer Batchman, our CEO, give him your favorite cucumber recipe. The man is obsessed.

Exeter Engineering Partners With Universities For Potato Research

Matt

Exeter Engineering is a proud partner to agronomy departments at universities around the United States. Our latest partner is the University of Maine. They’re using our AccuVision 360 optical sorter to gather data for research on post-harvest storage of potatoes. They needed a machine to quickly and accurately sort their research crops, giving them a accurate and consistent results. The AccuVision 360’s combination of superior presentation and industry-leading AI-powered optical grading was exactly what they needed.

The AccuVision 360’s ability to grade for both external and — with our Hollow Heart Detector — internal defects is key to ensuring that the data collected meets the projects needs. With this data, the researchers at the University of Maine could potentially lead to offering superior potatoes to consumers, reducing food waste and eliminating supply-chain inefficiencies.

Sending a Sidewinder (Sorter) to Australia

Matt

At Exeter Engineering, we make equipment for a variety of fresh produce applications. We are especially well-known for our optical sorters, with their industry-leading AI-powered ID Technology sorting suite. Over our decades of business, we knew that we had developed a good reputation in our “home” market in North America. Turns out people know us worldwide!

When a client in Australia contacted us about their mango packing needs, we knew just what to offer. The Sidewinder is one of our workhorse optical sorters. It’s good for a variety of produce types, including mango. We explained to our Aussie friends how the Sidewinder works: after gentle singulation, each mango is rotated 360 degrees under our high-definition, multi-spectral cameras. Those images are instantly analyzed and compared to our custom database of imagery, developed for each customer based on our vast library. Better imagery means better decisions means the best results on the market today.

They were convinced. We’re currently setting up and testing the Sidewinder’s camera box at the main plant, with the transport lanes taking shape down at the south plant. Soon, the entire sorter will be on its way down under. And a few weeks after that, our friends in Oz will be operating their Sidewinder…and will get to know the kind of quality engineering and construction Exeter Engineering has built our reputation on.

If you’re in the mango game, no matter where you are in the world, get in touch and see how the Sidewinder by Exeter Engineering.