There's a reason Exeter is in our name too

Uncategorized

Founded in 1978 in small-town Exeter, California, we’ve been part of our community for nearly 50 years. We’ve built some of the best optical and AI-powered grading systems on the market, shipping them worldwide—but California’s Central Valley is still home. We recently celebrated at Valley Strong Ballpark for Exeter Engineering Night at the Visalia Rawhide™. Baseball, hotdogs, and good friends—it was the perfect reminder of our community’s strength, which mirrors our company’s vitality. We like to say that there’s a reason “Engineering” is in our name, but “Exeter” is there too. Together, they capture who we are and what we do.

Got a fresh-produce project that needs help? We’d love to have you join our community of friends and customers. Until then, hope you’re having a great summer.

Wishing You A Wonderful World Cucumber Day

Uncategorized

Today is World Cucumber Day. At Exeter Engineering, we are proud to partner with farmers and packers to bring you the freshest, most delicious cucumbers available. Indeed, without our Sidewinder optical sorters with their ID Technology (that’s our exclusive AI-powered optical grading suite), your cucumbers might be a bit less fresh and delicious.

So, whether your partial to a cucumber in your G&T, fancy a bit of tzatziki or some raita, or just like a pleasing crunch in your salad, remember to enjoy a cucumber today. And next time you see Boomer Batchman, our CEO, give him your favorite cucumber recipe. The man is obsessed.

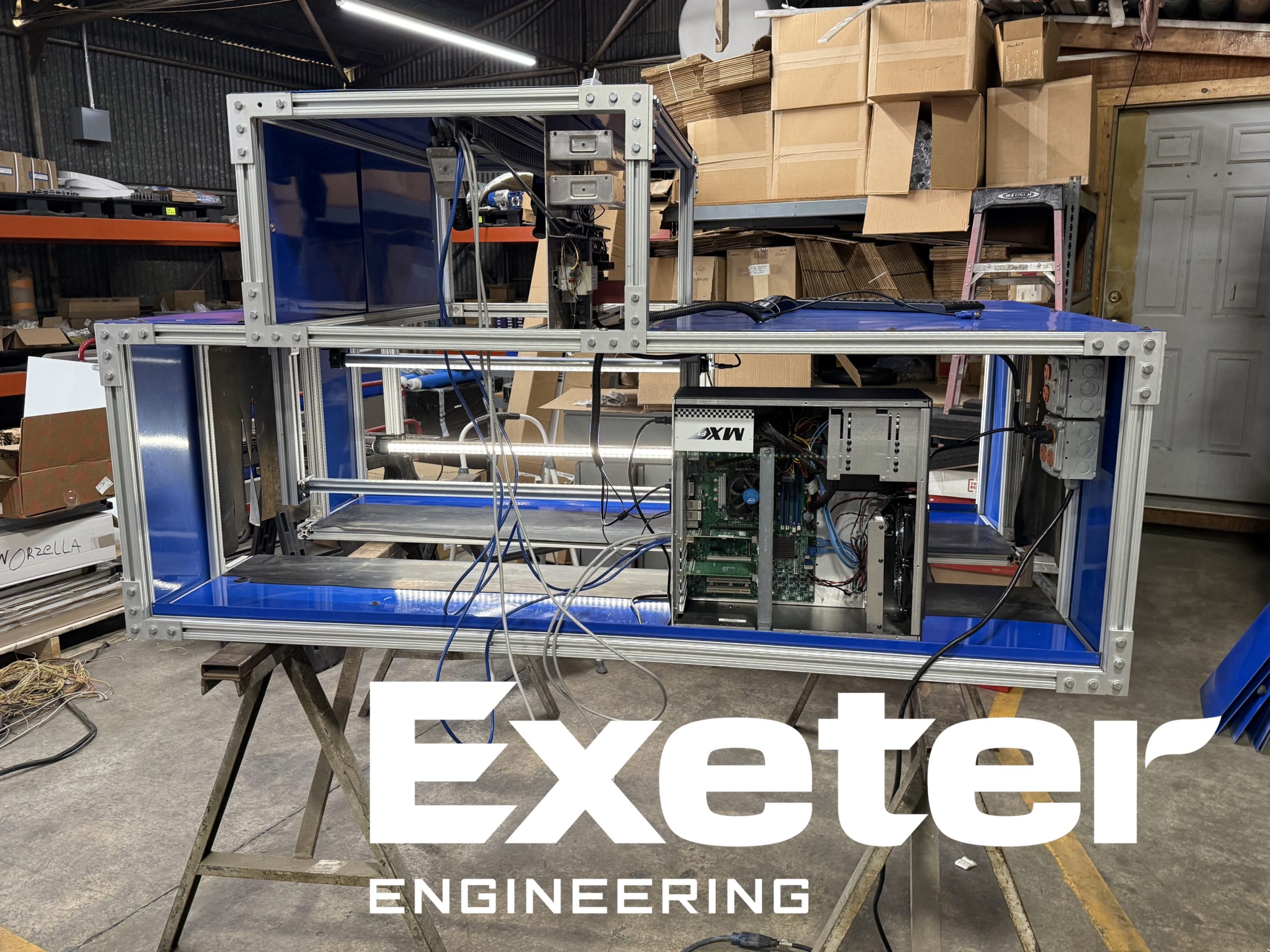

Sending a Sidewinder (Sorter) to Australia

Uncategorized

At Exeter Engineering, we make equipment for a variety of fresh produce applications. We are especially well-known for our optical sorters, with their industry-leading AI-powered ID Technology sorting suite. Over our decades of business, we knew that we had developed a good reputation in our “home” market in North America. Turns out people know us worldwide!

When a client in Australia contacted us about their mango packing needs, we knew just what to offer. The Sidewinder is one of our workhorse optical sorters. It’s good for a variety of produce types, including mango. We explained to our Aussie friends how the Sidewinder works: after gentle singulation, each mango is rotated 360 degrees under our high-definition, multi-spectral cameras. Those images are instantly analyzed and compared to our custom database of imagery, developed for each customer based on our vast library. Better imagery means better decisions means the best results on the market today.

They were convinced. We’re currently setting up and testing the Sidewinder’s camera box at the main plant, with the transport lanes taking shape down at the south plant. Soon, the entire sorter will be on its way down under. And a few weeks after that, our friends in Oz will be operating their Sidewinder…and will get to know the kind of quality engineering and construction Exeter Engineering has built our reputation on.

If you’re in the mango game, no matter where you are in the world, get in touch and see how the Sidewinder by Exeter Engineering.

Factory Fresh AccuVision XXL ready for a new home

Uncategorized

The AccuVision XXL is our largest sorter and is designed for watermelons and pumpkins. This machine was in use for years with one of our customers. They’ve recently traded-in this machine for a different model so we decided to refurbish it before we find it a new home. As part of that refurbishment, we are upgrading the camera box with new lighting, upgraded cameras and a new wiring system. The upgrades will allow this AccuVision XXL to offer industry-leading sorting of watermelons or pumpkins by weight, shape, size or external defects.

The carrier system is undergoing a similar upgrade at the South Plant. When we’re done with all the work, this AccuVision XXL will be factory fresh and ready to start a new life. This refurbishment is possible because of the quality engineering and construction that goes into every piece of equipment we make. If you’re interested in this AccuVision XXL or in any of the other equipment we offer, get in touch!

There is a reason Engineering is in our name (check out the video!)

Uncategorized

For 47 years, Exeter Engineering has been working with the fresh produce industry. And for each of those years, the meaning of our corporate name has remained the same: we don’t just build or sell equipment, we engineer solutions for our customers. Whether its designing a line to incorporate a new AccuVision 360 sorter into the tight quarters of an existing space, rationalizing and automating the weighing-bagging-palletizing portion of a major packing operation, or building an entirely new line in a recently erected facility, our engineers will be with you every step of the way to make sure your project meets your goals and works the way you need it to.

Click the link to check out a little video we did showing a bit of how we work to engineer solutions for our customers.

Hats Off To Formal Fridays

Uncategorized

An Exeter Engineering tradition since 1982, Formal Fridays are the one day every month when we dress in business attire and honor the wishes of our founder, Jeff Batchman. Jeff wore a suit and tie to work every day for nearly 50 years and always wished for Exeter Engineering to be known both for the quality of its products and the sharpness with which its employees dressed. Everybody here gets into the spirit of Formal Fridays: from the guys on the press break sporting natty bow ties, to the sales staff with their pinstripe suits, to the ball gown on at least one of our techs, everybody looks sharp, just the way Jeff liked it.

Formal Fridays are one of the things that makes Exeter Engineering a special place to work and a great team to work with.

2025 Citrus Showcase in Visalia, CA

Uncategorized

Exeter Engineering is to the California Citrus Mutual’s 2025 Citrus Showcase next week. The event is just down the road from our home in Exeter, at the Visalia Convention Center. We started working with the citrus industry in 1978 and continue to value those long-time relationships, providing superior equipment for citrus packing operations. If you’re going, stop by and say hello!

Don't let hollow-hearts give you the blues

Uncategorized

If your poor potatoes are suffering from hollow-heart problems, you need a solution that keeps your customers happy. To keep hollow-hearted potatoes from your best grades, you need Exeter Engineering’s Hollow-Heart Detector. Part of our ID Technology AI-powered grading suite — the Hollow-Heart Detector is an add-on x-ray that detects hollow-heart potatoes and removes them during your sorting. Simple, easy and consistent, Exeter Engineering’s Hollow-Heat Detector will chase your hollow-heart blues away.

Celebrating National Tater Tots Day with our friends in the potato industry

Uncategorized

Exeter Engineering happily celebrated National Tater Tot Day with our friends in the potato industry. We are proud to work with them to make sure the key ingredient of those crispy golden nuggets of deliciousness make it to where they need to be so we can all enjoy billions of tater tots each year. We hope you joined us in raising a tater tot to our friends the potato farmers and packers who made it possible.

The Oculus continues to climb the charts to new heights

Uncategorized

Exeter Engineering continues to install the popular Oculus 2000 compact potato sorter. We recently finished a project for our friends at the Associated Potato Growers, Inc, in Grafton, North Dakota. They replaced an old Odenberg with something that could provide gentler product handling, better sorting results, and still fit in their facility. Oculus 2000 fit the bill perfectly.

The Oculus 2000 features ID Technology, Exeter Engineering’s proprietary AI-powered optical grading suite. It also has the shortest drop height in the industry and is super easy to operate and maintain. Mike Torgersen, APGI’s manager, reports his membership are pleased with how quickly and seamlessly we were able to install the new sorter and even happier with the significant upgrade in sorting capability, which has yielded superior results to their old set-up.

If you’re in the market for a compact sorter that gives you superior results, is easy to maintain, and won’t ever be left unsupported, get in touch!

AccuVision Upgrade Program Update - Atlantic Potato Distributors

Uncategorized

The AccuVision upgrade program is in full swing! Exeter Engineering is working with customers to upgrade their existing machines to the latest in presentation and optical grading technology. That means they get cutting edge technology without having to buy a new sorter!

We recently completed an upgrade for our friends at Atlantic Potato, up in New Brunswick, Canada. They’ve had an AccuVision for 11 years and were interested in upgrading the machine so they could use our ID Technology AI-powered grading suite. They didn’t have the space or need for a new facility, so we had to complete the work in their existing packing shed in tight quarters: only 37 inches of headroom above the side rail of the sorter!

Exeter Engineering techs got the job done. We’ve replaced camera box and installed new cameras and electrics throughout. We also upgraded the controls, with a new 27 inch touch-screen control station, running the latest ID Technology version, customized to Atlantic’s product. While we were at it, we replaced the cables and cable tracks as well as replacing all of the kickers on all 12 lanes of the AccuVision.

The results are in and Atlantic Potato tells us they are very happy indeed! They are seeing a significant jump in grading accuracy with ID Technology, especially with its ability to detect growth crack, green defects, and pressure bruising. Size and shape detection are also way up, and the new ID Technology interface is much easier to use, especially on the new, bigger touch-screen.

At Exeter Engineering, we treat our customers as family, and families don’t stop being family after you haven’t sold them something in a while. That’s one big reason we started the AccuVision Upgrade Program: to continue offering value to our customers throughout the lifetime of the equipment they buy from us.

A new bell pepper line saves costs, increases productivity

Uncategorized

Our friends at A&B Costanza Farms in Sodus, Michigan recently asked us to help them design and build a new packing line for bell peppers. They wanted a line that would handle greater volume with better protection for their valuable crop. They were also hoping to reduce the number of people required to operate the line, even as they packed more product.

Challenge accepted.

Exeter Engineering worked with A&B Costanza Farms to understand their concerns and identify solutions to those problems that would fit into their budget and physical constraints. The result is a bell pepper line that delivers volumes of more than 45,000 lbs per hour with 30% fewer personnel and far less damage to their product than other lines.

The line centers on Exeter Engineering’s Sidewinder sorter, powered by our ID Technology AI-powered optical grading suite. ID Technology takes advantage of Sidewinder’s spinning presentation system to use its high definition cameras and custom-tuned LED lighting to capture superior imagery of every facet of each piece of product. Better imagery means better grading results, especially using our AI-powered grading features. The system sorts into three separate grades. It quickly identifies the presence and severity of discoloration (sun tan), shape, squatty defects, surface punctures, scarring and machine damage, grading each bell pepper by size, color, weight, external grade and overall shape.

The line also features:

- An XTR 500 Zone Dumper to receive the bell peppers into the line (and automatically clean the bins they arrive in for quick re-use!);

- An XTR 100 4-belt EvenFlow Accumulator to regulate the volume of product in the line, keeping it moving at a steady volume; and

- AccuCount Fillers, to automatically fill cartons with graded product…gently and without additional staff

The resulting line is a huge success. A&B Costanza farms has reduced their overhead while also increasing the quality of the product leaving their facilities. The flexibility of the ID Technology system also offers them the ability to quickly and easily respond to the market, increasing their bottom line without increasing their headcount.

If you’re thinking about adding or upgrading your packing solutions, contact the fresh produce packing experts at Exeter Engineering. Common sense engineering married with cutting edge technology since 1978.

The AccuVision Upgrade Program

Uncategorized

Throwaway culture. Planned obsolesce. Upgrade cycles. There are a lot of ways used to describe pushing someone to buy something new to replace something they already own, that’s working very well. If you’re like us, when you find a tool you can rely upon, you take care of that tool so it can continue doing its job well. That’s why we have always designed every product we make to be reliable for season-after-season, and we have always built those products to last.

Sometimes, though, the latest and the greatest innovation really is something you can use, and something that will really improve your business. In those times, you have to think seriously about investing in the new thing and deciding what sort of return on investment justifies the expense. That’s just business.

When we introduced our AccuVision 360 last year, we knew that the benefits it offered would tempt many of our loyal customers. The revolutionary presentation system, tightly integrated with our AI-powered ID Technology suite, all built on a super-robust modular system…it’s pretty tough to beat. We also knew that some of our customers wouldn’t be able to make the math work to justify a new machine when their existing AccuVision sorters were still working hard and doing a pretty good job.

Our customers are like family, and we if we can help, we will. We’re also engineers, so we knew that if we did some tinkering, we’d be able to come up with a solution that worked.

We did.

Introducing our AccuVision Upgrade Program. For customers with Exeter Engineering’s reliable workhorse AccuVision who want the latest and greatest without breaking the bank, we’ve got you. With the AccuVision upgrade, we’ll come and replace your existing carrier system with the AccuVision 360’s rotating carrier. We’ll also upgrade the optical sorting equipment with a new camera hood, new multi-spectral cameras, new LED lighting, and ID Technology’s latest software and controls. When we’re done, it’s like you have swapped out an old machine for the best machine on the market…without changing a thing about your packing lines or the reliability you’ve come to depend upon.

Cutting edge technology pared with common sense engineering…that’s Exeter Engineering. If you’re packing fresh produce, we’d love to help your business thrive.

Lone Wolf Farms loves their new Oculus

Oculus potato sorter

Uncategorized

We have recently installed several of our Oculus compact sorters around North America. Our customers are loving these sorters so much, we felt compelled to share a bit of feedback.

Lone Wolf Farms of Minto, ND recently added a new Oculus sorter. Lone Wolf’s Chris Bjorneby described a few of the ways that Oculus has improved their sorting:

• The ability of the Oculus to fully rotate the product underneath ID Technology cameras has meant better images and better sorting results the first time.

• They love Exeter’s ID Technology AI-powered grading suite and the fact that it uses an AI model we’ve tuned to regional defects/potato red skin found in their area, yielding superior results.

• The Oculus has a shorter drop than other sorters, so it is gentler on their No. 1 potatoes.

• The Oculus is easy to use. It has a flexible user interface and intuitive software. It’s fast and simple to run both AI-powered and “traditional” features, ensuring that each sort works right. And the 24-inch control screens enable operator to select any of the 21 features from a single-screen and see how the change will affect the ongoing sort, live.

• They appreciate our top notch customer service, from installation through operation. They were especially pleased to able to work directly with the software development team building their AI-model.

“We feel like we’re partners as much as customers,” Chris told us. “We appreciate the help that Exeter Engineering gives us to serve our own customers better.”

Check out the Oculus and get in touch!

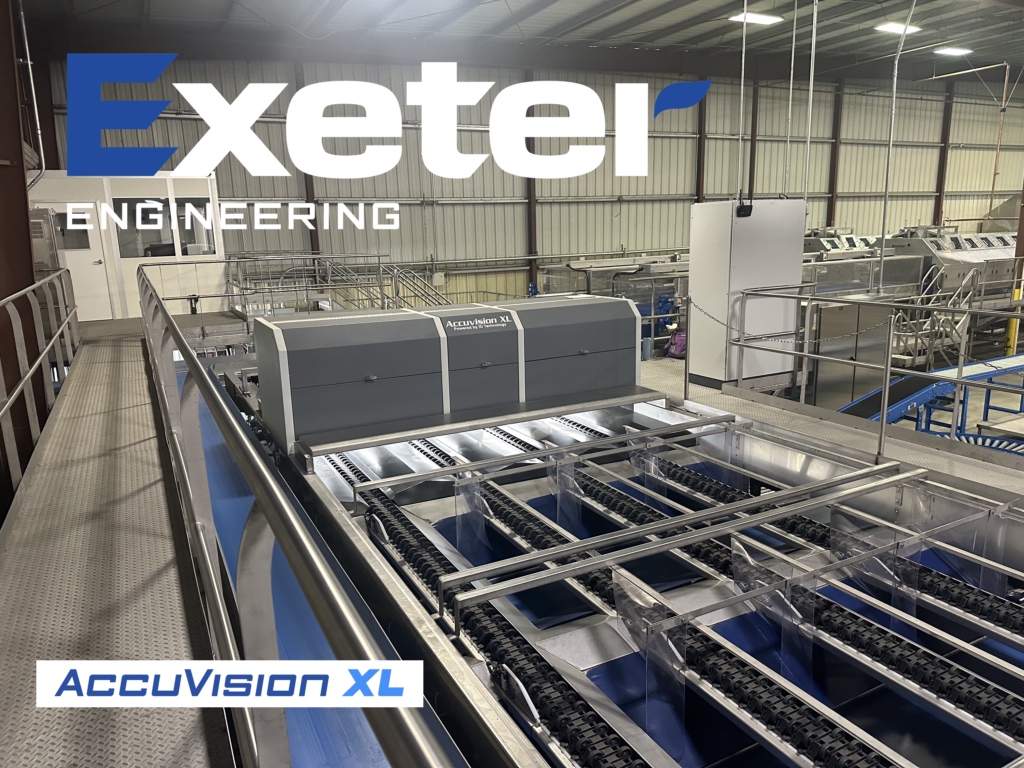

Honeydews and mixed melons

Uncategorized

Exeter Engineering recently completed installation of packing line for honeydews and mixed melons. The line features our AccuVision XL and uses ID Technology, our AI-powered grading suite — the first line anywhere to use artificial intelligence to grade those produce types. We worked with our good friends at Five Crowns Marketing to develop the new line and they liked it so much, we offered to make a case study in how Exeter Engineering can help melon packers everywhere. Check it out!

Exeter Engineering's ID Technology in the news

Uncategorized

Exeter Engineering recently attended the Washington Oregon Potato Conference at the Tri-City Convention Center in Kennewick, WA. It was a great opportunity to join our friends and customers in the area to talk spuds. We also showed off our new ID Technology AI-powered optical grading suite of HD Cameras, custom-tuned LED lighting and proprietary software. ID Technology will leverage our superior integration between presentation and vision equipment to get the best images available. Better images mean better results: up to 97% accuracy after a single pass. And ID Technology’s easy-to-use controls will make it a snap for even new staff to get results that only experienced staff are able to achieve using traditional optical sorting techniques alone.

The event was great and we enjoyed seeing everyone. We even made the local news! We are looking forward to returning in the future. If you’d like more information about ID Technology or Exeter Engineering’s optical sorting equipment for potatoes, get in touch.

Exeter Engineering helps customers upgrade to the newest version of ID Technology

Uncategorized

CAMBRIA, WI – Teams from Exeter Engineering are working with customers across North America to upgrade their ID Technology system to version 2.07. One of our teams was recently in Wisconsin to help a customer upgrade their existing AccuVision sorters to the latest version of ID Technology. The customer had not previously used an Exeter Engineering AI-powered sorting system, relying on third-party add-ons in the past. We worked with the customer to develop a custom-engineered upgrade, featuring a new camera box to house the ID Technology 2.0 suite of multi-spectral cameras, custom-tuned LED lighting. We paired this upgrade in optical technology with an improved set of AI-powered controls and control interfaces.

Currently in the testing phase, these upgrades will reduce the customer’s sorting costs significantly, reducing reruns and providing superior, first sort results.

Exeter Engineering's ID Technology in the news

Uncategorized

Exeter Engineering recently attended the Washington Oregon Potato Conference at the Tri-City Convention Center in Kennewick, WA. It was a great opportunity to join our friends and customers in the area to talk spuds. We also showed off our new ID Technology AI-powered optical grading suite of HD Cameras, custom-tuned LED lighting and proprietary software. ID Technology will leverage our superior integration between presentation and vision equipment to get the best images available. Better images mean better results: up to 97% accuracy after a single pass. And ID Technology’s easy-to-use controls will make it a snap for even new staff to get results that only experienced staff are able to achieve using traditional optical sorting techniques alone.

The event was great and we enjoyed seeing everyone. We even made the local news! We are looking forward to returning in the future. If you’d like more information about ID Technology or Exeter Engineering’s optical sorting equipment for potatoes, get in touch.

Tortilla chips and guacamole: two great tastes that taste pretty darn good together. We are happy to celebrate National Tortilla Chip Day with that hallowed combo, and happy to work with avocado growers and packers around the world to get their crop to you, so you can enjoy it too.

From avocados to pumpkins, Exeter Engineering partners with our friends in agriculture and fresh produce packing to make sure that you have access to the best, freshest produce anywhere. So while you raise a chip to celebrate, remember the farmers and suppliers who made the guacamole happen too. And enjoy!