Oculus - the best compact potato sorter - now made in the USA

News

This Fourth of July, we are celebrating the independence of our country and the people who built, maintain and protect the things that make it such a wonderful place to live. We hope you and yours enjoy a great holiday as well.

We are also celebrating the Oculus, our compact, three-drop sorter featuring ID Technology…now made in the USA! The Oculus uses a unique rolling presentation system to maximize image quality for grading with our ID Technology system, Exeter Engineering’s industry-leading AI-powered grading suite. It’s also a rugged, easy-to-maintain sorter, perfect for sorting any variety of potato, clean or direct from the fields.

Now that the Oculus is made in the USA, it’s not subject to any of the tariffs or fees of competing compact sorters. If you’re in the market for a compact optical sorter for your potato crops, celebrate Independence Day and celebrate American-made. And get in touch if you’re in the market for the best compact potato sorter available today…

Exeter Engineering Partners With Universities For Potato Research

News

Exeter Engineering is a proud partner to agronomy departments at universities around the United States. Our latest partner is the University of Maine. They’re using our AccuVision 360 optical sorter to gather data for research on post-harvest storage of potatoes. They needed a machine to quickly and accurately sort their research crops, giving them a accurate and consistent results. The AccuVision 360’s combination of superior presentation and industry-leading AI-powered optical grading was exactly what they needed.

The AccuVision 360’s ability to grade for both external and — with our Hollow Heart Detector — internal defects is key to ensuring that the data collected meets the projects needs. With this data, the researchers at the University of Maine could potentially lead to offering superior potatoes to consumers, reducing food waste and eliminating supply-chain inefficiencies.

Training on Agrimech Equipment – Complete!

News

Exeter Engineering is a proud partner of Agrimech, one of Europe’s leading manufacturers of automated machinery solutions. As part of our commitment to quality and reliability, our staff is fully trained to keep Agrimech products humming, season after season. One of our Field Service Technicians, Gunnar Batchman, has just completed Agrimech’s intensive four-week service-training program. He was congratulated by Darren Smith of Agrimech, after passing with flying colors.

Exeter Engineering is happy to offer our customers Agrimech’s products for weighing, packing and palletizing. These innovative yet reliable solutions will speed your lines and reduce labor costs…all at a very attractive price point. The Zeus Palletizer (pictured behind Gunnar and Darren), for example, is capable of palletizing boxes, trays, bags, sacks, bales and nets quickly and easily. The Zeus is easily operated and maintained, and can work on a variety of product ranges, including potatoes, onions, and hard squashes…among others. No other machine on the market today offers the build quality, ease of use, and trouble-free operation that the Zeus does. And Exeter Engineering is the only company in North America can offer you the Zeus and any required after-sales service.

So if you’re in the market for some seriously fast palletizing equipment, please get in touch. We would love to help you find the perfect solution for your packing operation.

ID Technology is AI that works...today

News

You’re probably hearing a lot of about Artificial Intelligence these days. It seems like every third news article talks about how transformative AI will be, how it will change the world.

It’s all future tense.

If you work in fresh produce, you know that the future is tomorrow but there’s work to do today. A prediction or forecast is only as useful as it is accurate. But something that works today…is accurate today…that’s useful.

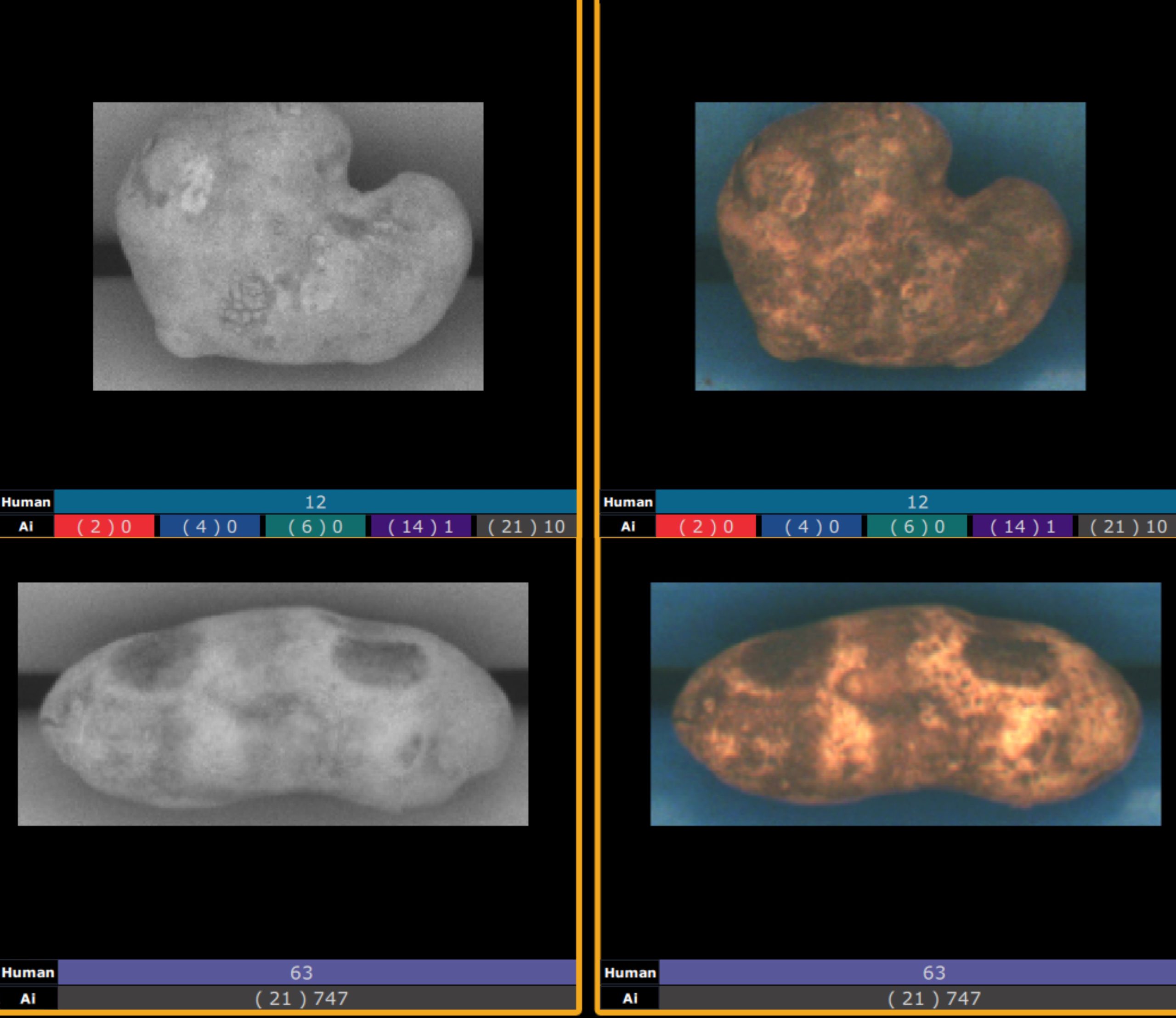

That’s Exeter Engineering’s ID Technology, our Artificial Intelligence-powered optical grading suite. Using a combination of machine learning, advanced imaging, and a huge proprietary database, ID Technology instantly analyses images of each piece of your product and grades it according to the parameters you set. Want to change those parameters? Easy. ID Technology’s intuitive interface makes it fast and easy. It shows you live images, so you can see what your changes mean in real time, and it gives you predictions of how those changes will affect the whole sort. ID Technology also works with our industry-leading Hollow Heart Detector to grade for interior molds and cavities.

We are constantly improving ID Technology’s capabilities. Upgraded cameras featuring multi-spectral capabilities, better algorithmic performance, and more are coming soon. It’s available on all of our sorters…today. Don’t wait for the future to reap the benefits of Artificial Intelligence. Get in touch to see how ID Technology can help you today!

Guacamole time!

News

At Exeter Engineering, one of our favorite meals is…anything that has guacamole. 😎 Over the years, we’ve partnered with many avocado producers and we know what it takes to get a good avocado from the orchard to your table. That’s one of the reasons that one of the first products we set our new AccuVision 360 sorter to work on was the avocado. Using our industry-leading ID Technology, AI-powered optical grading suite, the AccuVision 360 will help you quickly, accurately, and gently sort your avocado crop, maximizing your profit… and minimizing the time before it can become guacamole! It works pretty darn good on mangoes too! Check out the AccuVision 360 product page or get in touch to learn more.

AccuVision 360 in action

News

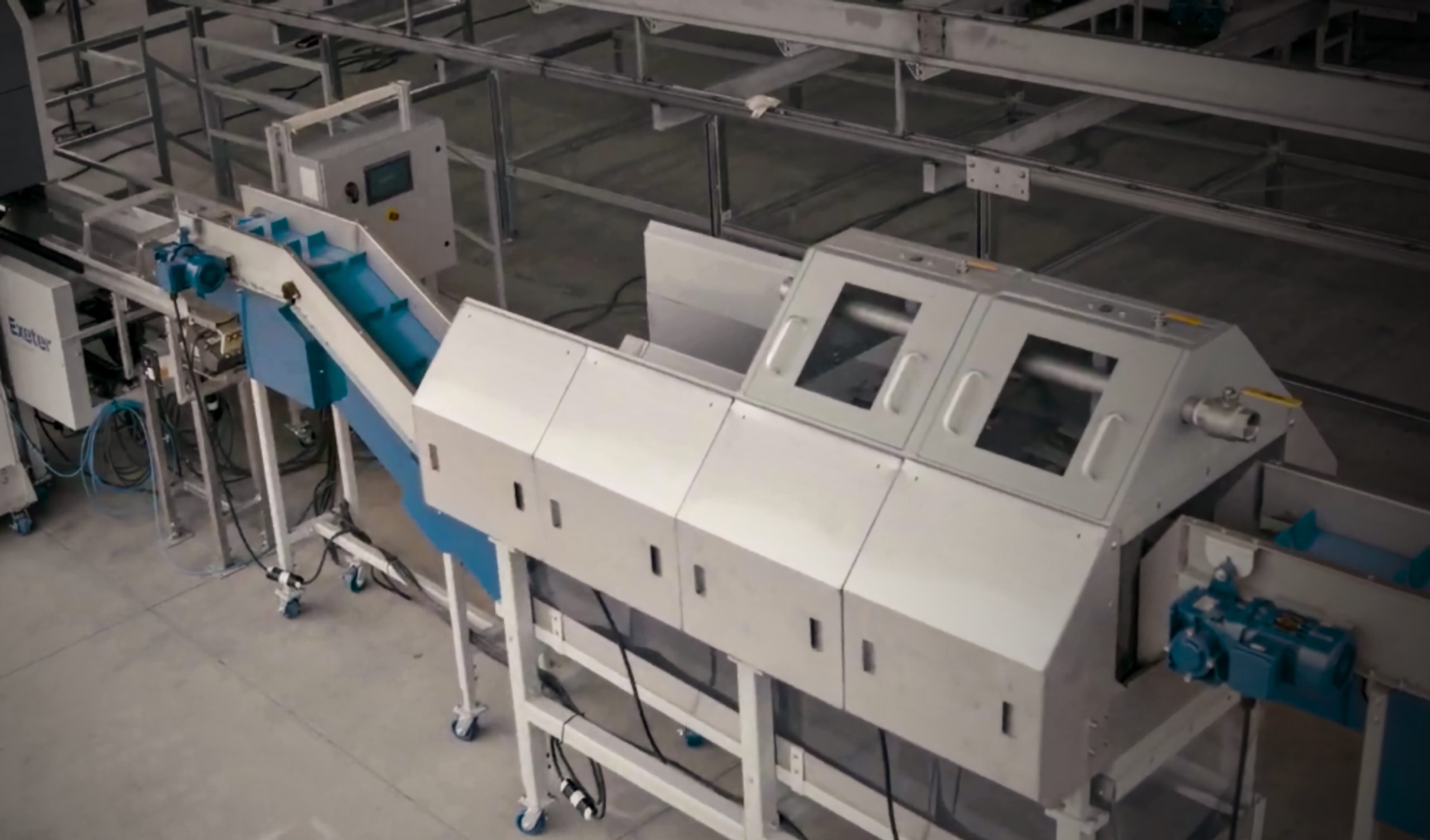

Here’s a little video we shot of our newest sorter, the AccuVision 360, in action on some potatoes. The AccuVision 360 represents another giant stride forward from Exeter Engineering. It is one of the fastest machines out there and the best machine we make to take advantage of ID Technology — our industry leading, AI-powered optical grading suite. Check out the product page or get in touch to learn more.

A new melon line taking shape

News

Our installation team is working diligently in Southern California to assemble and commission this melon line for the upcoming season. That’s an AccuVision XL they’re installing in the photos. Excellent choice! 🍈 🍉

Exeter Engineering is going to the 2024 Citrus Showcase

News

We are pleased to announce that Exeter Engineering will be once again attending California Citrus Mutual’s 2024 Citrus Showcase in Visalia, California on March 14th. We hope you will join us at the Visalia Convention Center for this fantastic event.

Exeter Engineering has partnered with the citrus industry since 1978. For 46 years, we have helped countless farmers, packers and other folks in the business make their operations smoother and improve their bottom line. So, if you are at the Showcase, please stop by and say hello. We would love to talk to you about we can help grow your business.

The revolutionary AccuVision 360…now available

News

EXETER, CA – The AccuVision 360 — Exeter Engineering’s revolutionary new optical sorter for oblong-shaped produce — is now available. Combining a unique presentation system, blazing speed, and our proprietary ID Technology suite of high-definition, multi-spectral cameras, custom-tuned LED lighting and AI-powered sorting, the AccuVision 360 is faster than any similar machine on the market today. Start 2024 off with some blazing speed…try the AccuVision 360 today.

To learn more, visit our AccuVision 360 page or drop us a line at sales@exetereng.com.

Join the revolution!

Exeter Engineering debuts our new look

News

EXETER, CA – Exeter Engineering today unveiled our new corporate identity. Our new logo reinforces our commitment to our customers, while recognizing our past and present as a family-owned and operated business. The word mark incorporates our full name — Exeter Engineering — emphasizing our continuing commitment to building solutions for our customers. We also added a stylized potato leaf to let our friends in the fresh produce industry know how much a part of our family we consider each customer. And the logo mark features two dynamic capital Es, harkening back to our first logo in 1978 while incorporating the cutting edge technology we provide today, and the energy we will carry into our future. Both marks include new shades of blue, reflecting the blue of the sky over the Sierra Nevada mountains, always visible east of our facilities.

The new logo is featured on our new website. Please come take a look — we are at www.exeterengineering.com — and find out how we can help your business meet its challenges, now and for years to come.

Exeter Engineering is developing Foreign Debris Detection

News

EXETER, CA – Exeter Engineering is developing an industry first, optical-powered Foreign Debris Detection system for chip-potato packing lines. Combining our proven ID Technology suite of cameras and custom-tuned lighting with AI-powered image recognition, the Foreign Debris Detection system identifies walnuts and golf balls in the product stream…before they cause you or your customers any headaches.

Coming in the Fall of 2023, the Foreign Debris Detection will be available as a stand-alone add-on to existing Exeter Engineering infeed systems or we can engineer a solution to add the system in between parts of existing conveyor systems. Contact us today — at sales@exetereng.com or by phone at (559) 592-3161 — to learn more.