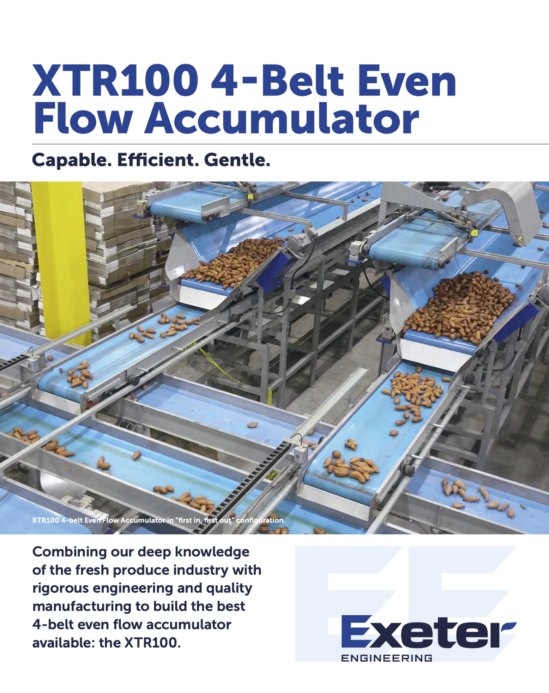

The best evenflow accumulator for fresh produce on the market today

The XTR100 4-Belt EvenFlow Accumulator is useful for a variety of tasks in your operations that require gentle accumulation and controlled release of product. As a purpose-built evenflow accumulator for fresh produce, the XTR100 provides precise product handling, flexible flow control and custom configurations to match any production line. With first-in, first-out or first-in, last-out configurations, this machine will ensure that you have a flexible path from bin to sorter or from sorter to packing equipment. Its design and operations will keep your product in pristine condition, as well, maximizing your return on investment.

Download Product Brochure

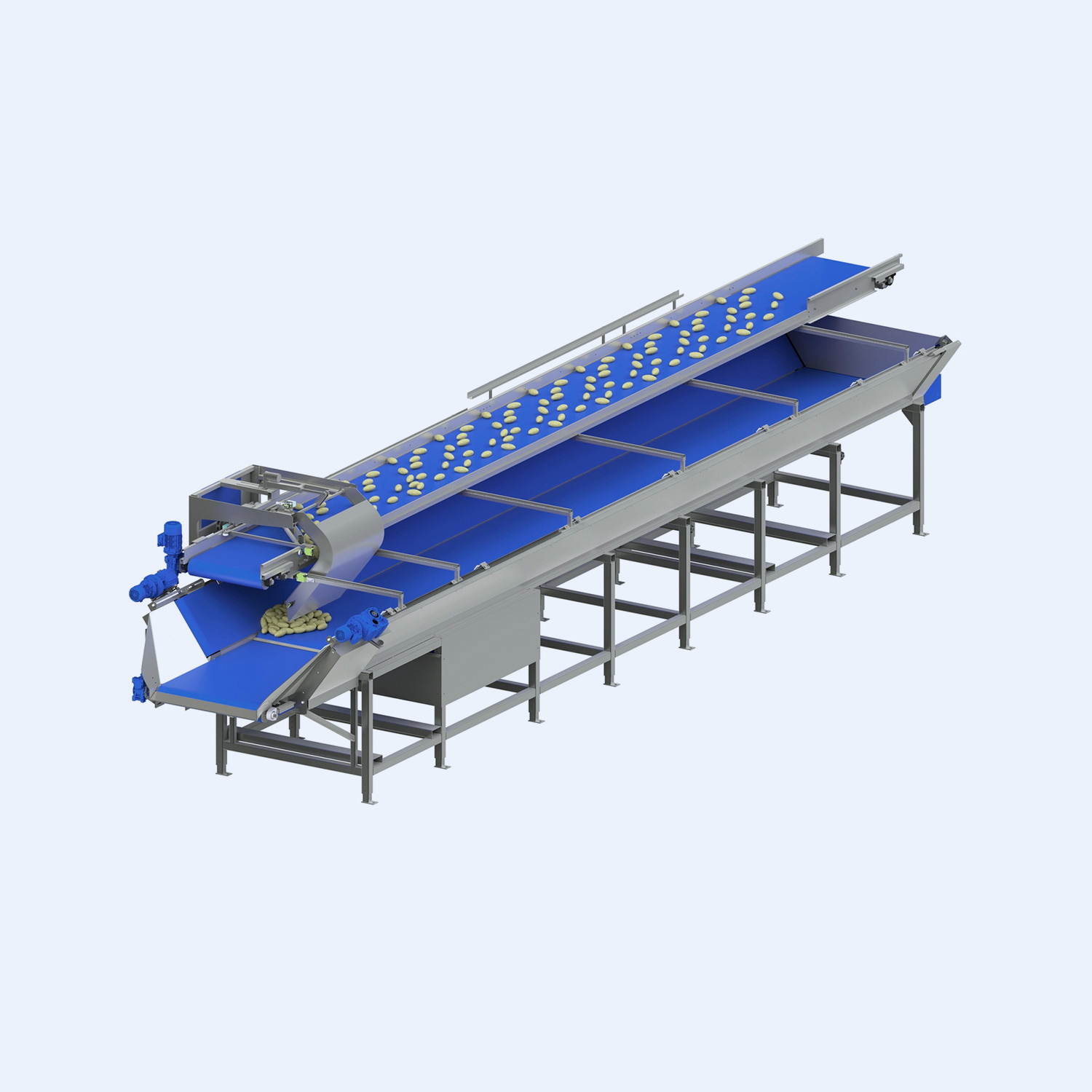

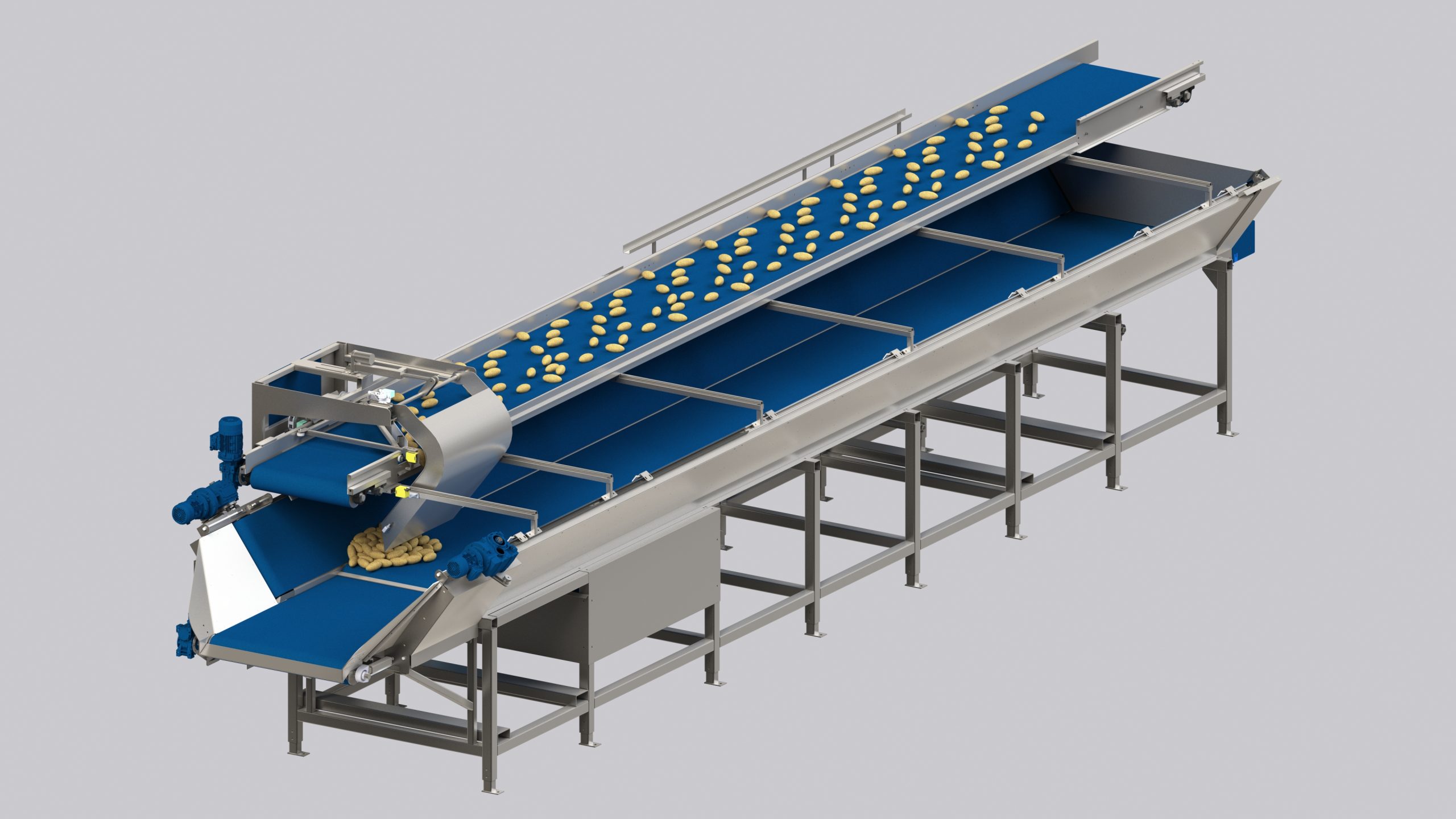

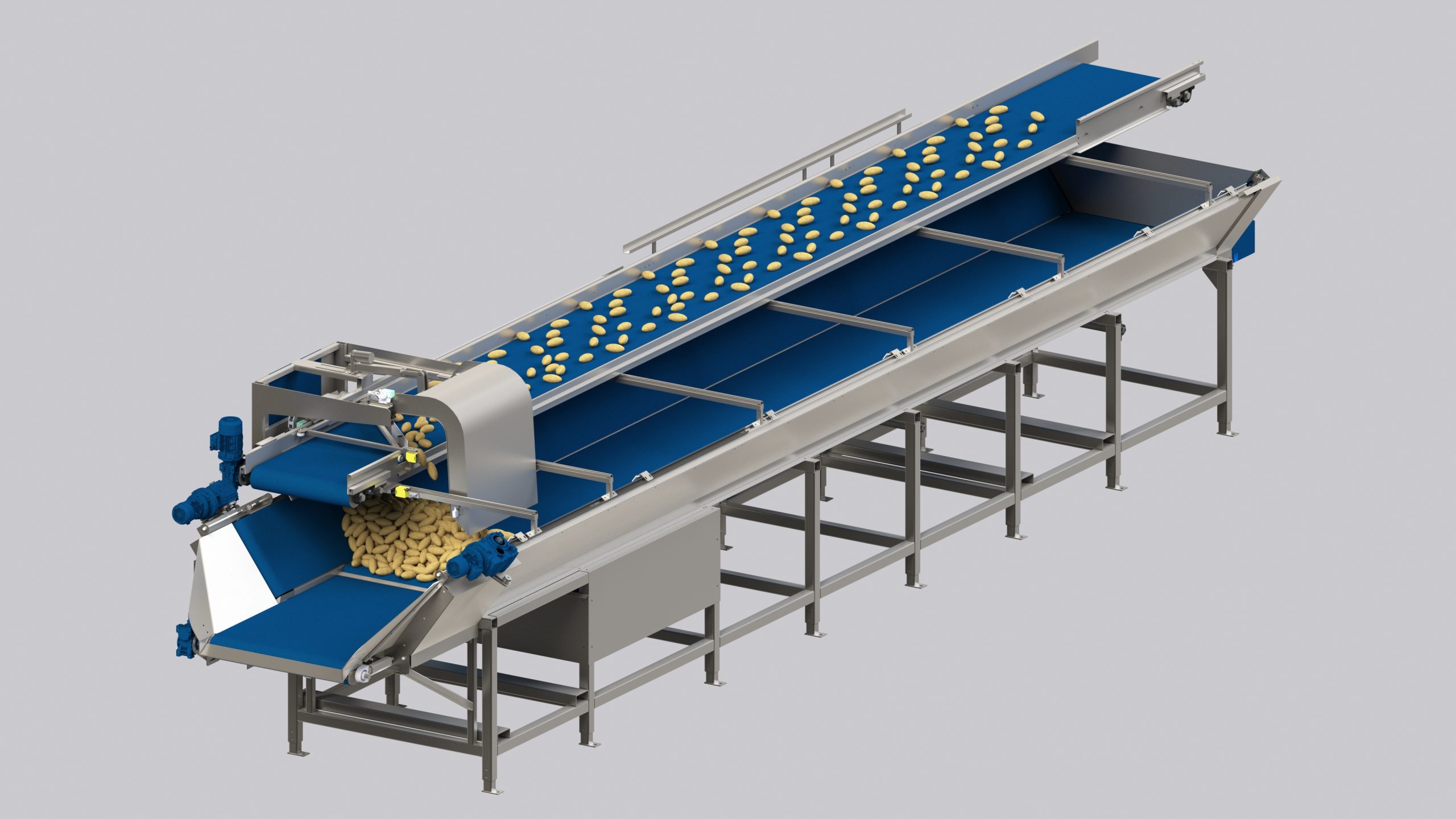

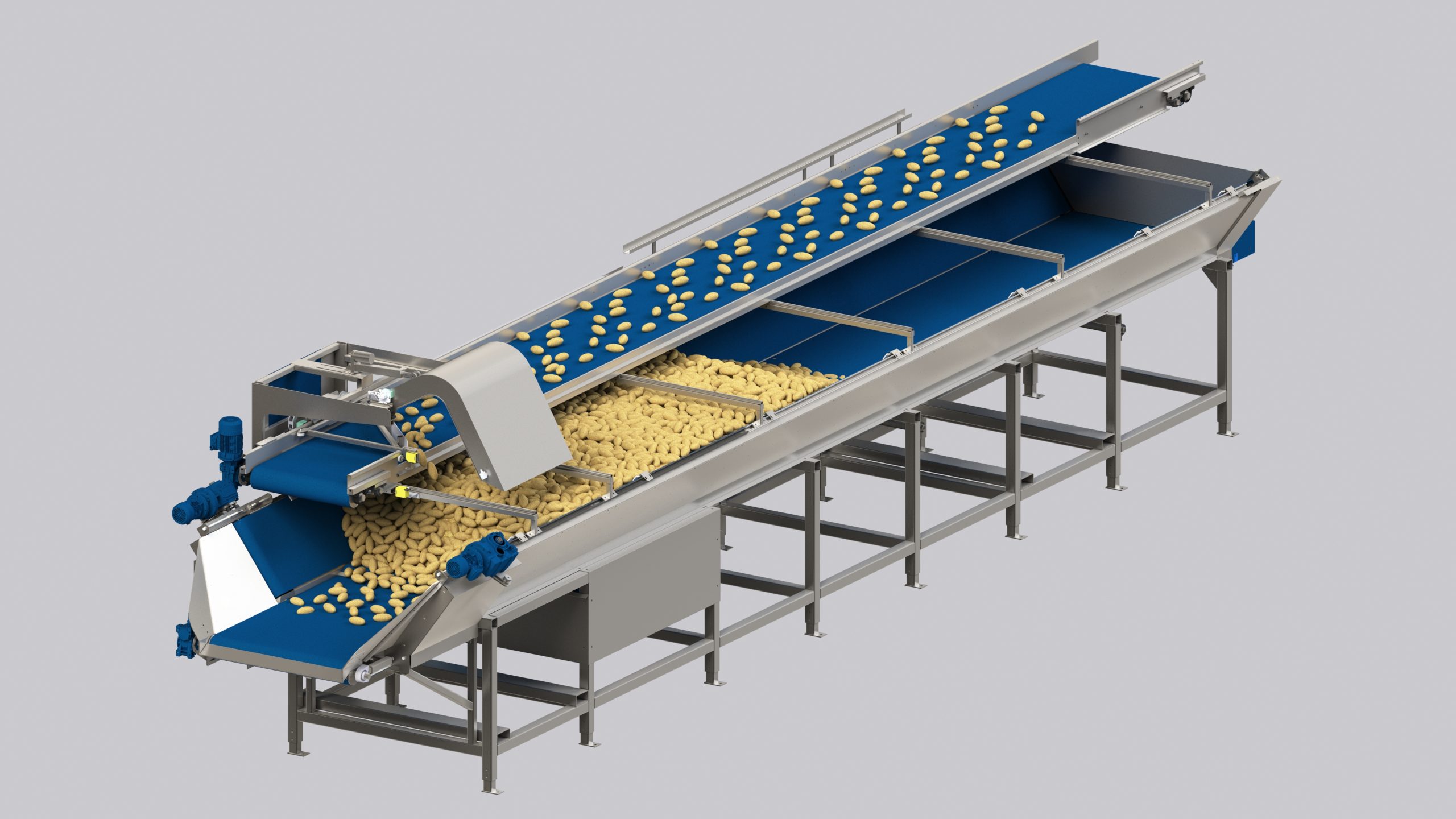

The XTR100 4-Belt EvenFlow Accumulator is an extremely gentle method of accumulating and conveying fresh produce. Product is collected in a 3-sided conveyor system, where the 3-sides are connected by an angled backstop. When the XTR100 is empty, the backstop is in the full forward position. As the system begins to fill-up, the backstop gradually moves backward. A photo-eye, measuring the product depth, controls the motion of the backstop. System dimensions and holding capacity are adjustable to suit the commodity and customer.

Whether you need the oldest product to be packed first, or your most recent product to be routed to the sorter, the XTR100 4-Belt EvenFlow Accumulator offers you the capabilities you need.

The XTR100 offers both FIFO and LIFO capabilities, allowing seamless adaptation to various packing and sorting strategies. With a holding capacity of 5,000 to 6,000 pounds and a customizable frame to match your product type and available space, this accumulator ensures reliable buffering between stages without compromising quality. Flow sensors automate the fill and release cycles, while pintle-lined chutes or angled backstops guarantee soft contact for delicate items. Designed to integrate with telescoping conveyors and compatible with our XTR500 Zone Dumper, the XTR100 streamlines your operations while keeping product movement smooth, consistent and damage-free.

- First-in, first-out (FIFO) or Last-in, first-out (LIFO) configurations available

- Releases product gently to maintain a continuous, even flow

- Flow sensors to control bin filling and emptying

- Holding capacity of 5,000 to 6,000 pounds

- Each unit custom built to meet your size and product needs

- Pintle-lined chute (FIFO) or angled backstops (LIFO) ensure gentle handling

- Designed for use with a telescoping conveyor for product delivery to multiple distribution points

- Can be combined with XTR 500 Zone Dumper

Construction

- Made in Exeter, California

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards

The XTR100 4-Belt Accumulator ensures continuous, even flow of product with FIFO or LIFO configurations. It maintains product integrity between stages and reduces clogging risks. Contact us to add XTR100 to your packing process.