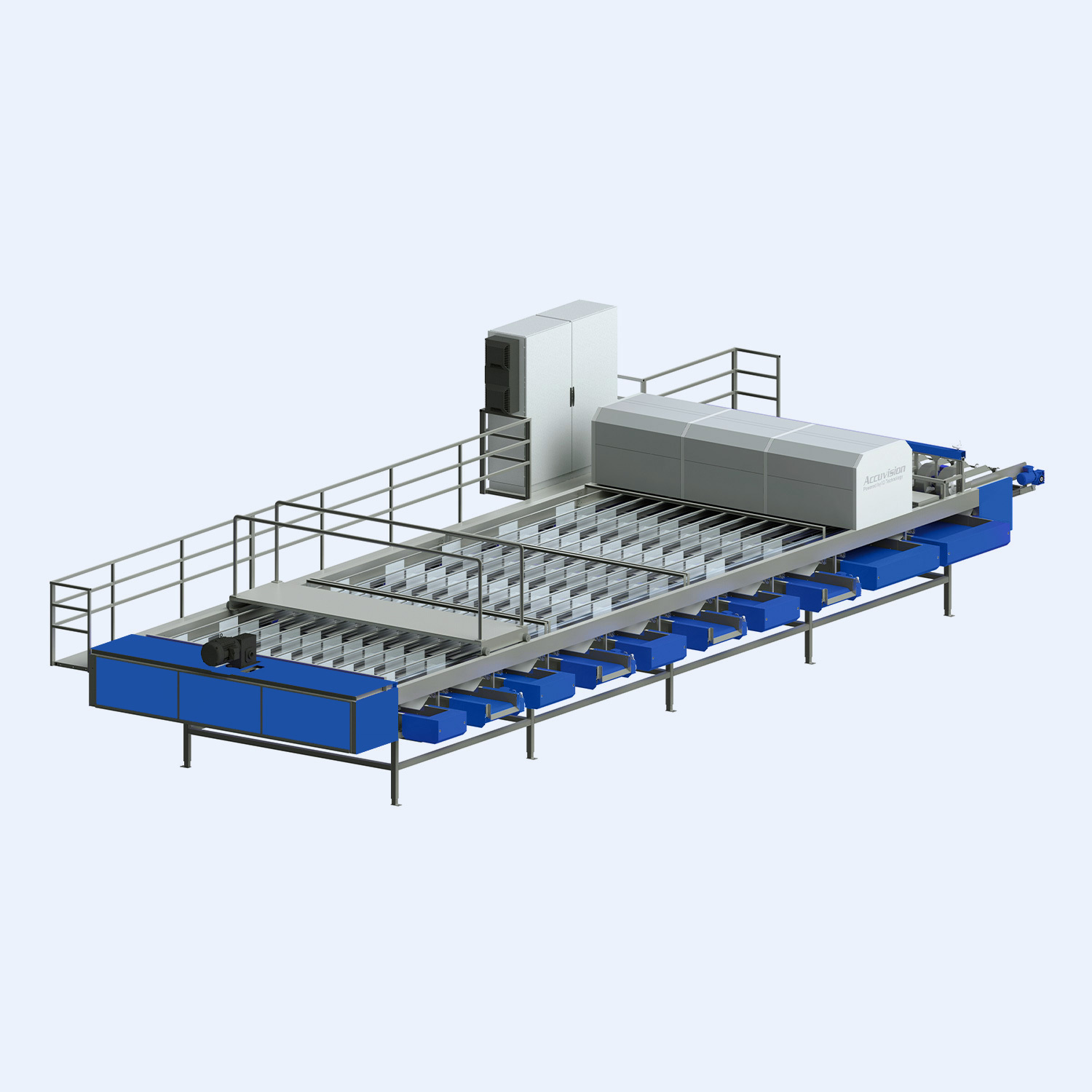

The multi-drop oblong-shaped produce optical sorting machine that fits your needs and your budget

The AccuVision is a highly accurate multi-drop sorter for use on oblong-shaped produce. Boasting exceptionally low operating cost, combined with our ID Technology AI-powered sorting capability, the AccuVision offers state-of-the-art performance and ultra-low operating costs all in a package tailored for your needs… and your budget. As a high-performance oblong-shaped produce optical sorting machine, it’s optimized for products like potatoes and sweet potatoes, delivering consistent results at high speeds.

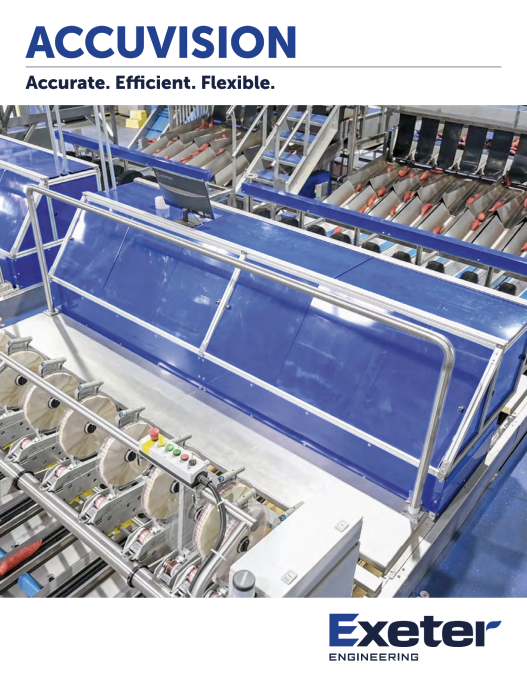

Download Product Brochure

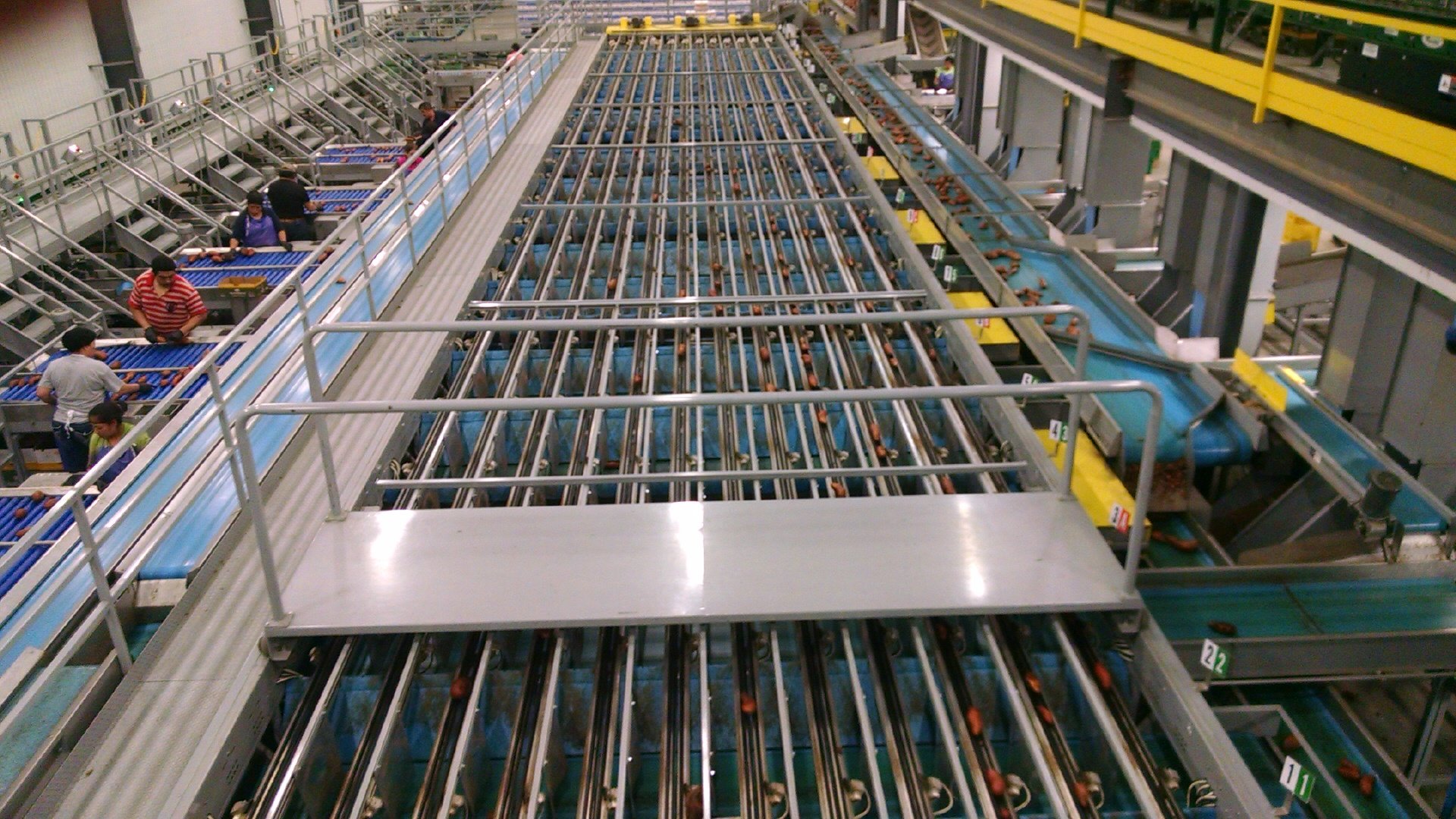

AccuVision sorters are designed to sort oblong-shaped produce such as potatoes and sweet potatoes. With a high-capacity and a labor-free, automatic infeed system, your products are gently delivered to the sorter and processed quickly and efficiently.

Exeter Engineering’s exclusive ID Technology system provides optimal sorting results on the AccuVision. Using high-definition, multispectral cameras mounted at opposing 45-degree angles and custom-tuned LED lighting, the AccuVision’s ID Technology suite takes multiple high-resolution images of each piece of product in both visible and infrared spectrum. These images are instantly compared to the database and used to sort your product using the parameters you’ve set.

ID Technology can sort three or more categories, across all lanes of your AccuVision. If you want to tweak your sorting, ID Technology’s easy-to-use software makes it simple and the live imagery shows you exactly how your changes will affect the product you’re sorting — in real time.

AccuVision is a robust machine, built to sort multiple products, season after season. Its unique cable transport system is uniquely suited to the challenges of sorting oblong shaped products at high volume. This machine is built tough, with a minimum of moving parts. That makes the AccuVision quiet, durable, and both simple and easy to maintain.

Built to handle up to 90,000 pounds per hour, the AccuVision excels at sorting elongated crops such as potatoes and sweet potatoes across up to 12 lanes and 30 drops per lane. Its robust cable transport system ensures smooth handling of fragile produce while maintaining speed and accuracy. With the ability to classify products into up to 30 separate grades per lane, and optional x-ray capabilities for internal defect detection, AccuVision brings advanced sorting power to fresh produce operations of any scale. Constructed from 304 stainless steel with Allen Bradley components and blue PVC belts, it meets or exceeds all food safety and quality standards — delivering long-term reliability and value with minimal maintenance demands.

- Available in configurations from 2 to 12 transport lanes

- High volume: from 15,000 – 90,000 lbs. per hour

- Capable of up to 30 separate classifications, per lane

- ID Technology package, with custom-tuned lighting in visible and infrared spectrum and high-definition, dual camera system

- Reliable, easy to maintain transport system

- Can be equipped with x-ray capabilities for internal crop analysis to detect hollow heart, cell granulation and other internal defects

- Easily paired with AccuFill and AccuCount carton filling systems

Construction

- Made in Exeter, California

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Blue PVC belts

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards

The AccuVision sorter offers precise, AI-driven grading for oblong produce like potatoes and sweet potatoes. Its modular, multi-lane system and cable transport design ensure high-capacity performance with gentle handling. With optional x-ray capabilities and easy integration, AccuVision is a future-ready solution for evolving packhouse needs. Contact us to discuss how AccuVision can enhance your sorting line.