Rugged and ready to gently wash your products

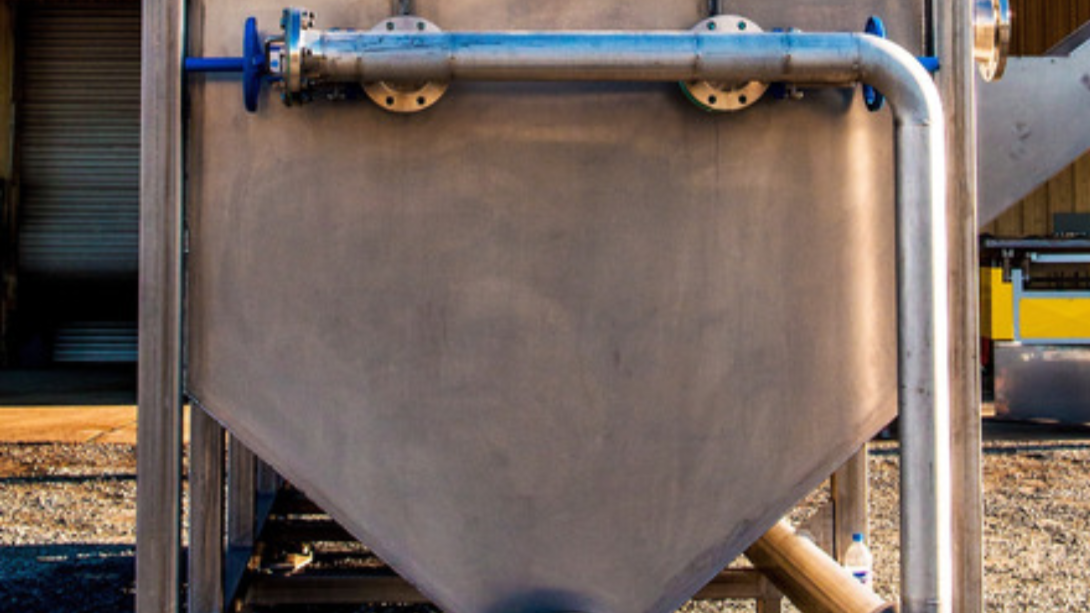

Series 4000 Wet Reception Tanks are designed to receive your product in efficiently and gently. Their robust design and tough construction mean that they will last for years, making your lines run smoother and giving you a solid return on your investment.

Download Product Brochure

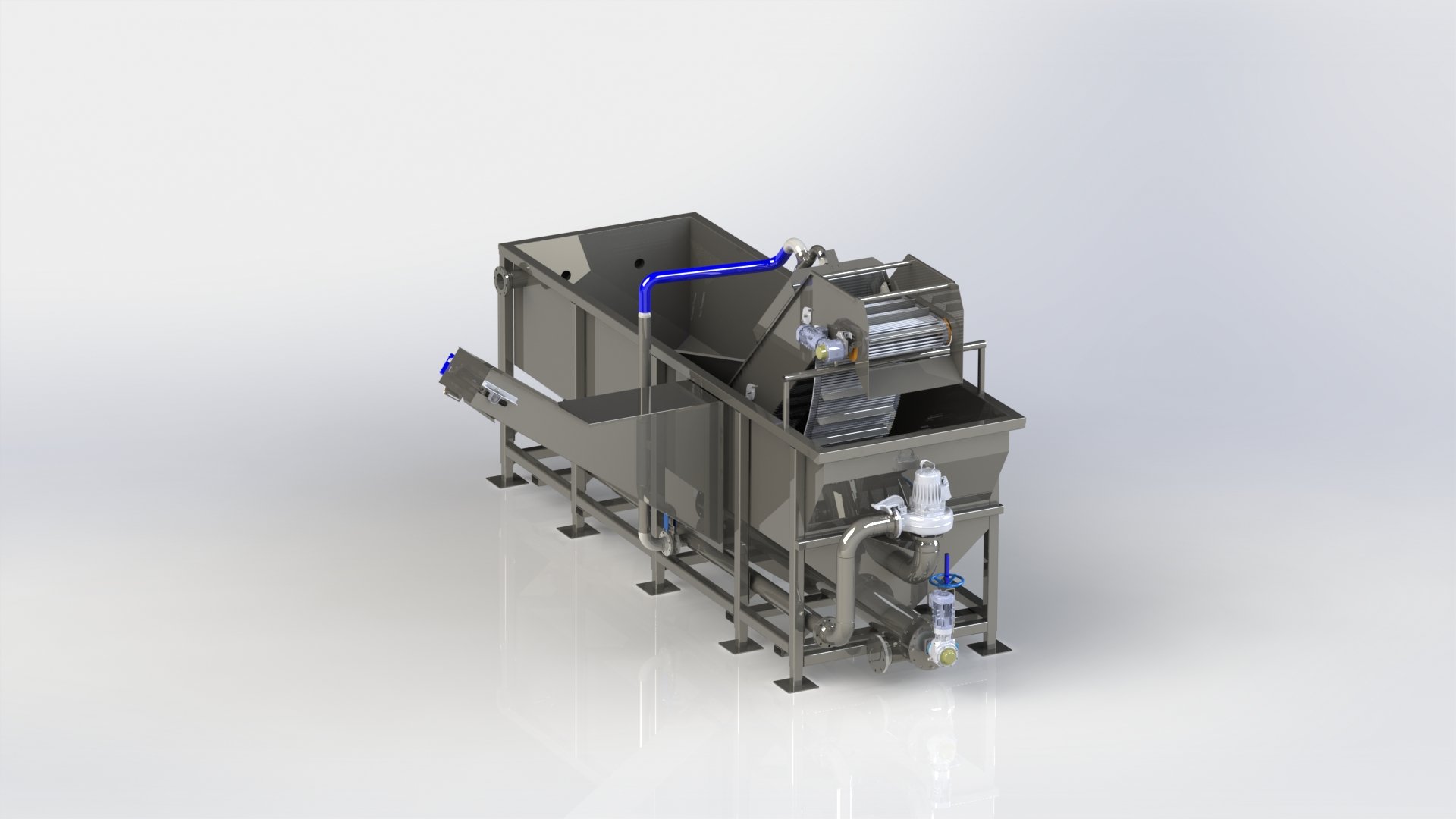

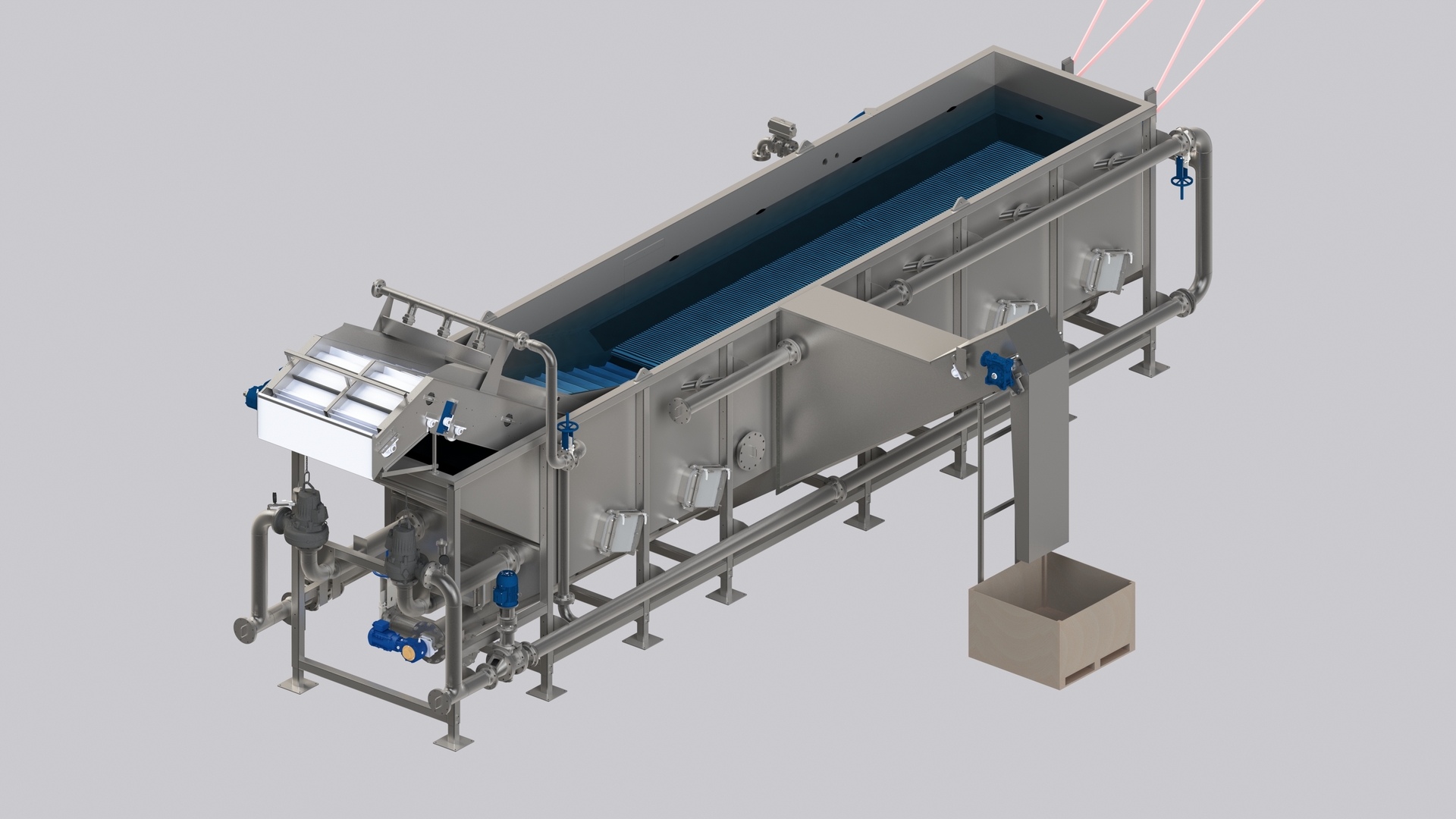

- Gentle product handling to prevent damage when receiving product

- Initial soaking and cleaning of product

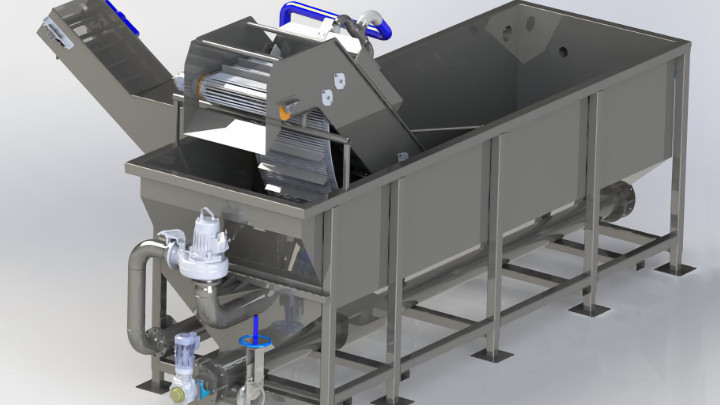

- Auger sludge removal system

- Electronic variable speed drives on pumps to control flow rates

- Custom capacity, based on your production needs

- Integrated freshwater rinse spray bar on discharge elevator

- Quick release maintenance access doors

- Optional shredder to removing objects that could plug water lines and maintain flow

Series 4000 Wet Reception tanks offer a flexible design, giving you the ability to receive bulk product or to integrate it as part of an automated bin dumping system. However you use it, it is a gentle way to wash your product and move it along your packing lines.

All Series 4000 Wet Reception Tanks are customized for the application and volumes you require. These tanks provide a gentle pre-soak and their discharge elevator has a final fresh water rinse. Centrifugal pumps circulate the water to remove sediment, and an auger system removes what sinks to the tank’s bottom This system allows for the water to be used over and over, reducing water usage while maintaining effective cleaning. And when it is time, there are several conveniently located quick-release access hatches that permit the Series 4000 Wet Reception Tanks to be serviced and inspected quickly and easily.

Our Series 4000 Wet Reception Tanks are flexible. They can be used in in conjunction with standard bin tippers (over the side), tippers that lower into the tank (rotating to dump the product) or Exeter Engineering’s XTR500 Portal Dumper. We offer the option of an optional industrial shredder to ensure debris like root stringers will not clog the lines, creating forward movement in the tank. Series 1500 De-stoners and Series 1600 Floating Debris Removal systems pair well with these tanks and are available as an option.

Capacity (lbs/hr)

Construction

- Made in Exeter, California

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards