A produce de-stoner and debris removal that offer fast and certain cleaning

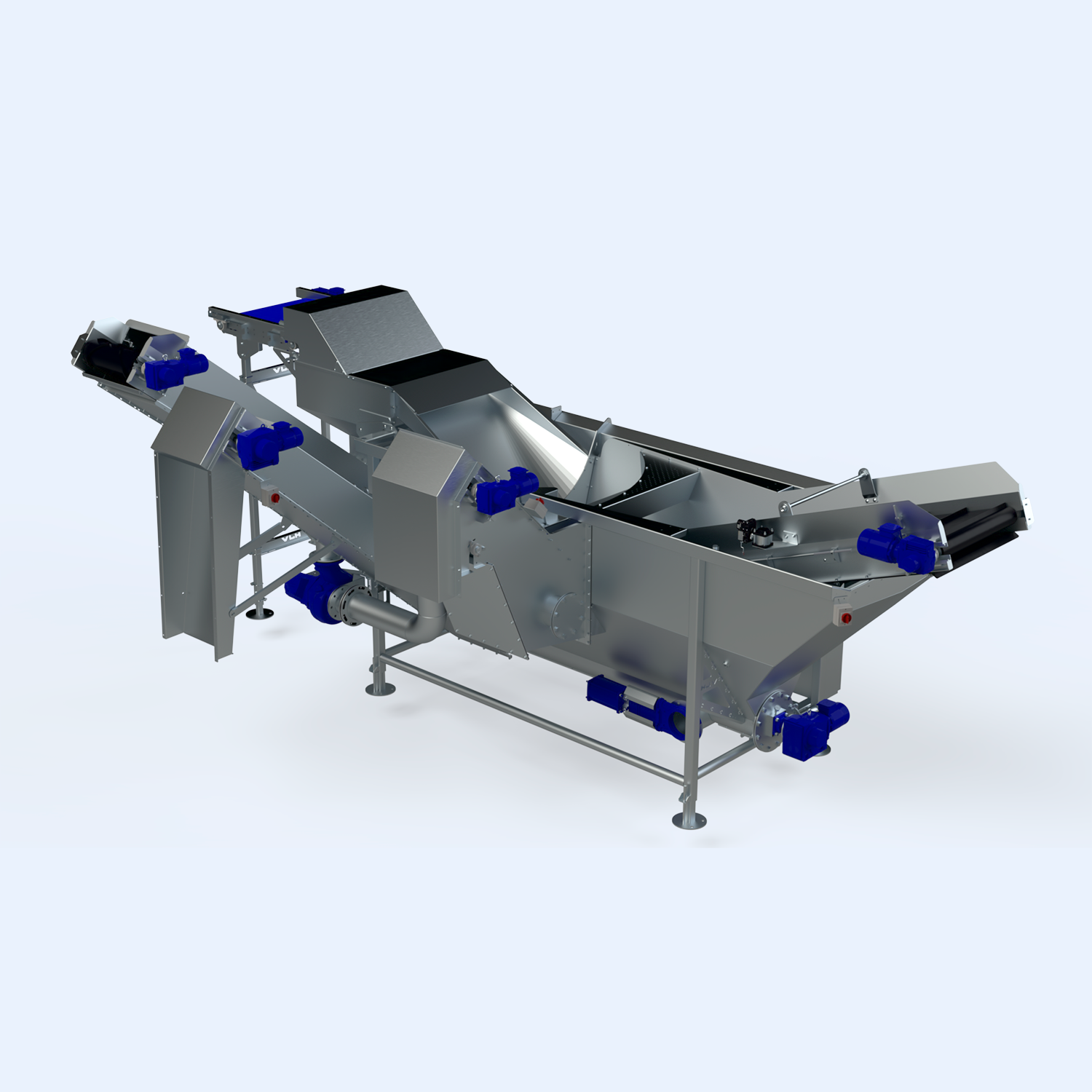

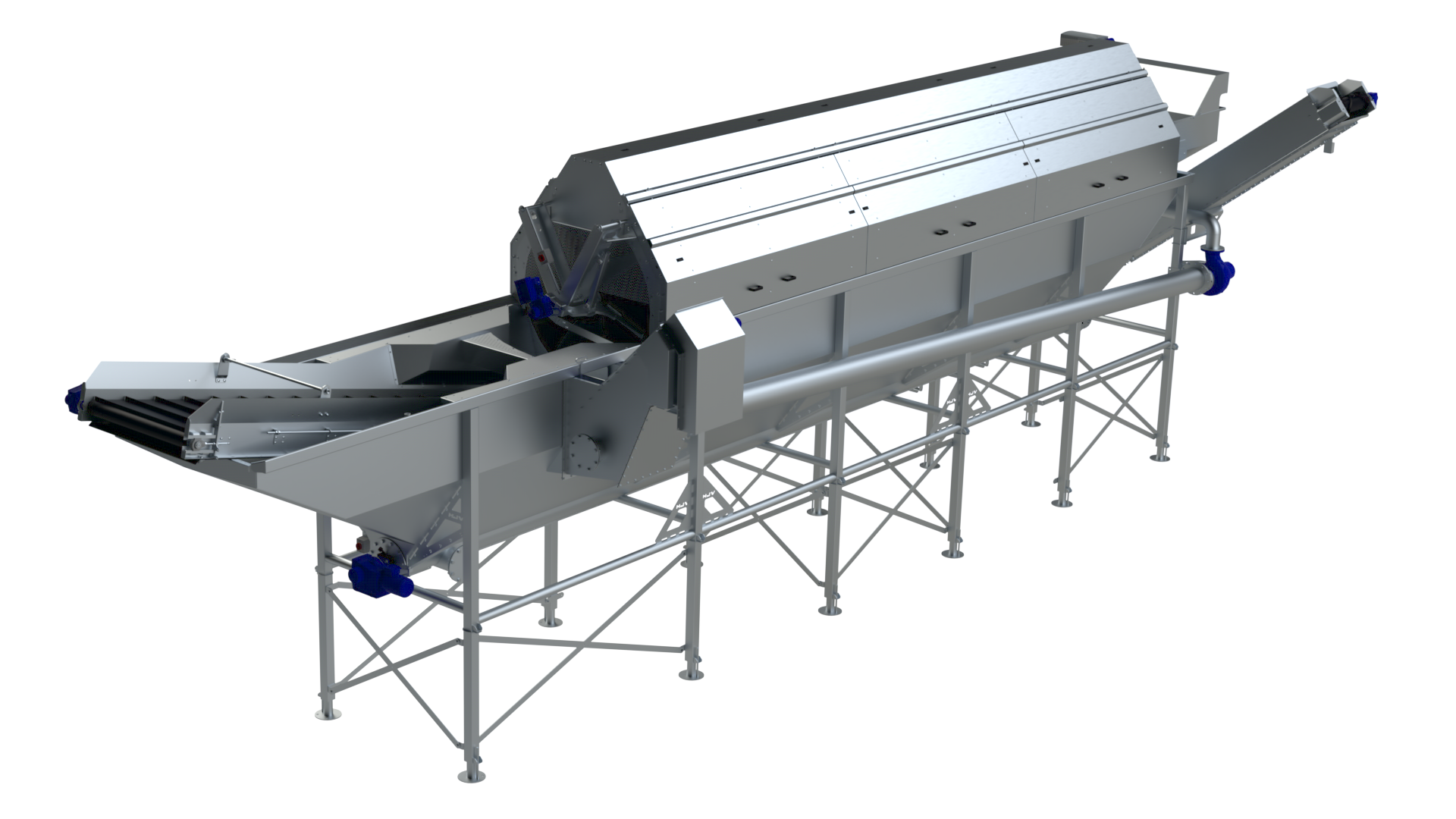

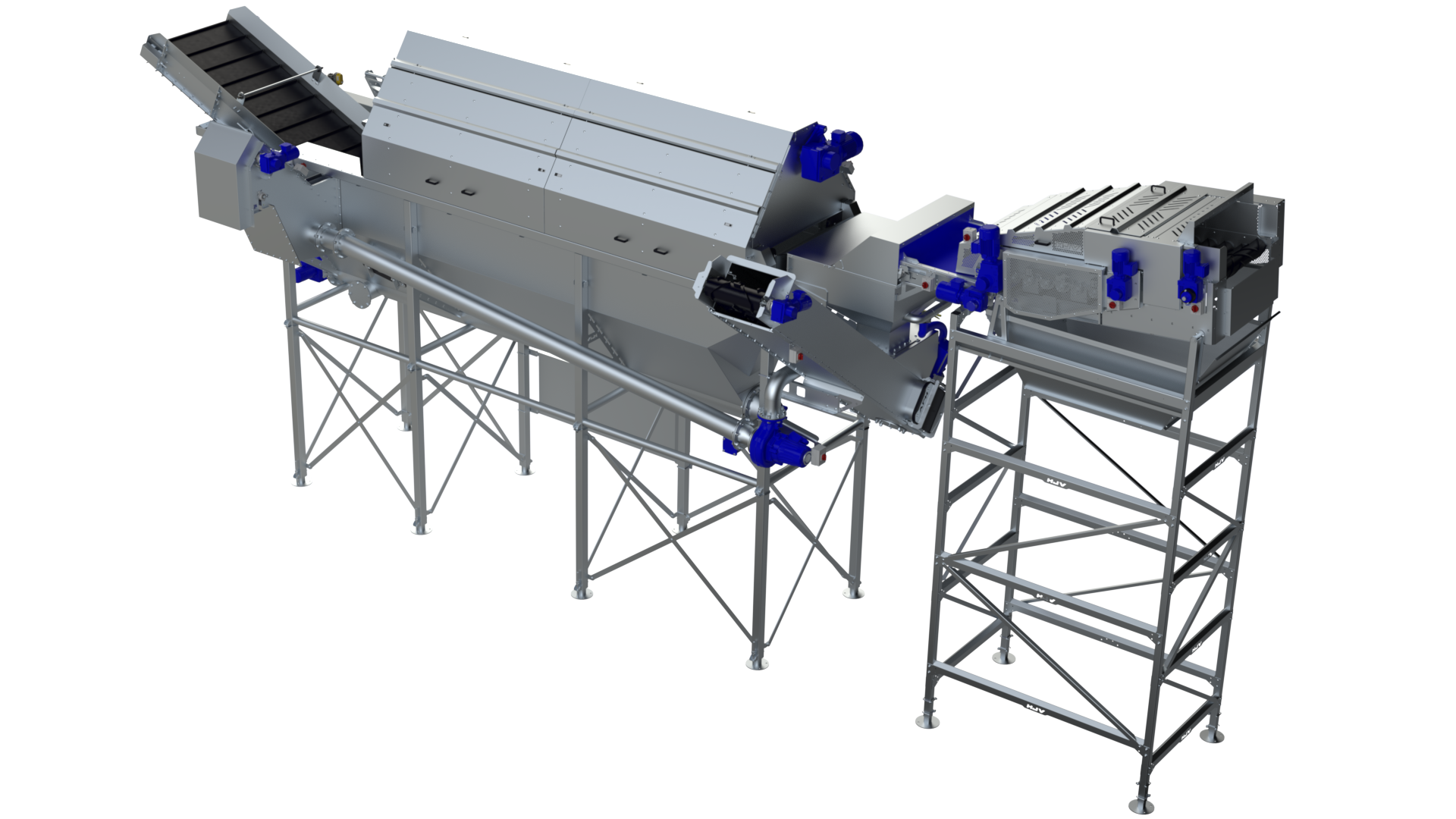

The Series 1500 De-Stoner offers a flexible solution to remove stones and clods from your crops, while the Series 1600 Floating Debris Removal System does the same for crop debris that floats. Together, the produce de-stoner and debris removal ensure your crop reaches the next stage of processing clean, undamaged and debris-free. The Series 1500 is available in two configurations: as a standalone machine or integrated into the Series 1000 Barrel Washer. Both configurations are easily combined with the Series 1600 as part of an automated chain of cleaning and preparation for your sorting process.

Download Product Brochure

The Series 1500 De-Stoners are engineered with your business in mind. They use a water weir system to effectively remove stones and clods. High-capacity pumps transport removed debris from the crops, and quick-release doors allow you clear the tanks quickly and easily. Simple controls provide the ability to fine-tune your cleaning level, so you use only the amount of time and water that are required.

Both the standalone and integrated versions of the Series 1500s are built with the future in mind. The standalone unit is designed to be easily upgradeable to a full washer solution. The integrated de-stoner works hand-in-hand with the Series 1000 Barrel Washers to remove all heavy debris at the start of a wash system, reducing the possibility of product damage or bruising. Both designs ensure that, no matter how long your product has been stored after harvest, only the intended product makes it through to the next stages of washing and sorting.

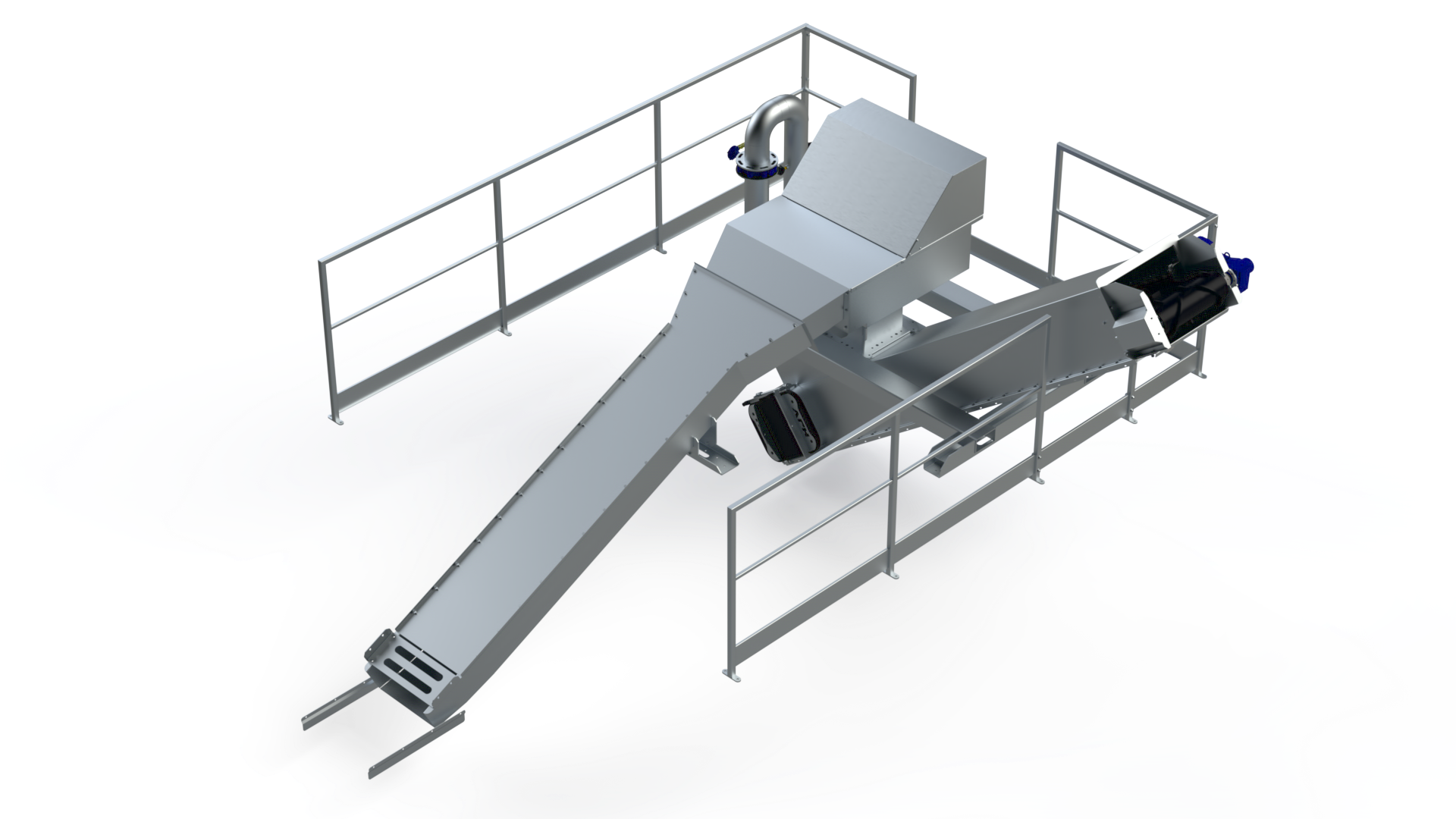

The Series 1600 Floating Debris Removal System pairs well with the Series 1500 to remove debris the floats. Using a rotating cleated belt, the Series 1600 continuously skims the downstream end of your washing/soaking tanks to remove debris and prevent it from clogging your sorter infeed or other equipment down the line from your washing stations. The Series 1600 adjusts so you can assure that all floating debris is removed, no matter how much product or water is in the tank.

Built for efficiency and reliability, the Series 1500 De-Stoner uses a water weir system and a rugged open impeller pump to quickly separate heavy debris from produce. With available widths of 36″, 48″, and 70″, and durable rubber chevron belts, it provides customizable handling for a range of crops. The system is available as a standalone unit or integrated into the Series 1000 Barrel Washer, offering flexibility for upgrades and space constraints.

The Series 1600 Floating Debris Removal System complements this process by continuously skimming the water’s surface with a cleated belt, removing lightweight material that could clog or damage downstream equipment. Constructed from 304 stainless steel and fully adjustable to any water level, it ensures consistent debris removal regardless of tank load or crop volume. When paired, these two systems create a comprehensive cleaning line that minimizes product loss and maximizes wash quality.

Series 1500 De-Stoner:

- High-capacity and robust solids handling pump

- Durable rubber chevron elevator belt to handle stones

- Shared water supply from washer reducing overall water usage

- Simple valve adjustment to fine tune stone removal

- Quick releasing door for cleaning and access to tail of elevator

- Infeed chute available in 36-, 48- or 70-inch widths

- Gate valve discharge for waste water

- Open impeller pump which does not require filters

Series 1500 De-Stoner product details:

Specifications

- Rugged construction; stainless steel construction optional

- Pump: 7.5kw Sewabloc

- Elevator Motor: 0.75kw 3 phase

- Elevator Belt: 600mm wide rubber chevron cleated belt, 25mm high cleats at 250mm pitch with endless belt joints

Construction

- Made by HJV Engineering in Alliston, Ontario, Canada

- Meets or exceeds all major government and retailer standards

Series 1600 Floating Debris Removal System product details:

Specifications

- Rugged construction: 304 stainless steel standard; other weights optional

- 24-month warranty

Construction

- Made in Exeter, California

- Meets or exceeds all major government and retailer standards

This de-stoner removes clods and stones using a water weir system and rugged chevron belt. Integrated or standalone, it protects downstream equipment. Contact us to keep your line free of damage-causing debris.