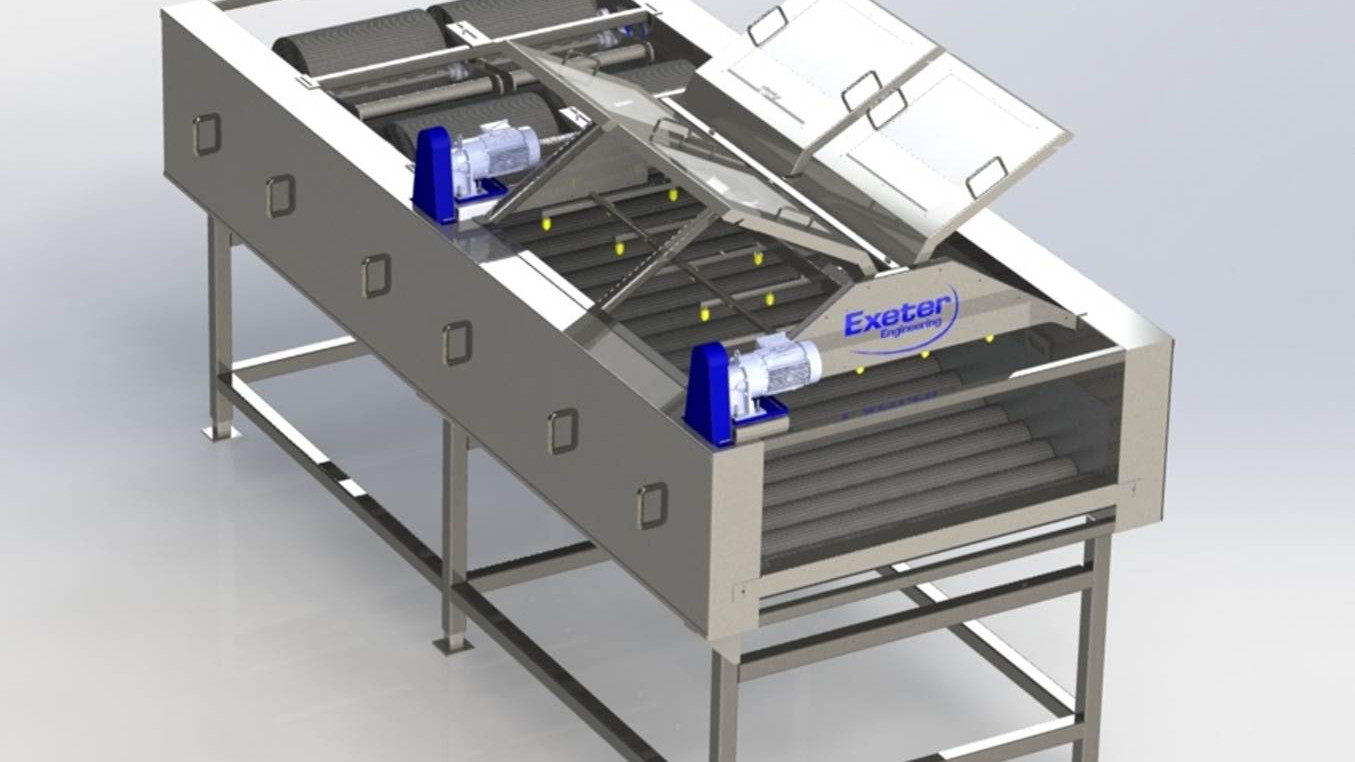

A custom horizontal brush washer that’s built tough and is easy to maintain

The Series 1200 Horizontal Brush Washers is a custom horizontal brush washer, offering unmatched serviceability, robust performance and configurable options for wet or dry cleaning. It features an innovative design that allows brushes to be replaced with the end bearings still attached. This reduces the time required for maintenance or brush replacement by up to 100%, compared to competitors.

Download Product Brochure

Series 1200 Horizontal Brush Washers can be built with 4-, 5- or 6-inch diameter brushes, and can be constructed to any width or length. The Series 1200s feature an innovative design that allows the brushes to be replaced with the end bearings still attached, greatly reducing the amount of time required for maintenance or brush replacement. They can be configured to dry or use and added spray bar options to use water.

All Series 1200 units can be made of either stainless steel (for wet wash applications) or mild steel (when used as a dry brush unit), giving you just the right brush washer at just the right price point. Every Series 1200 Horizontal Brush Washer uses robust square tubing support frames and 10 gauge formed steel to ensure your brush bed will last for many seasons, giving you a solid return on your investment.

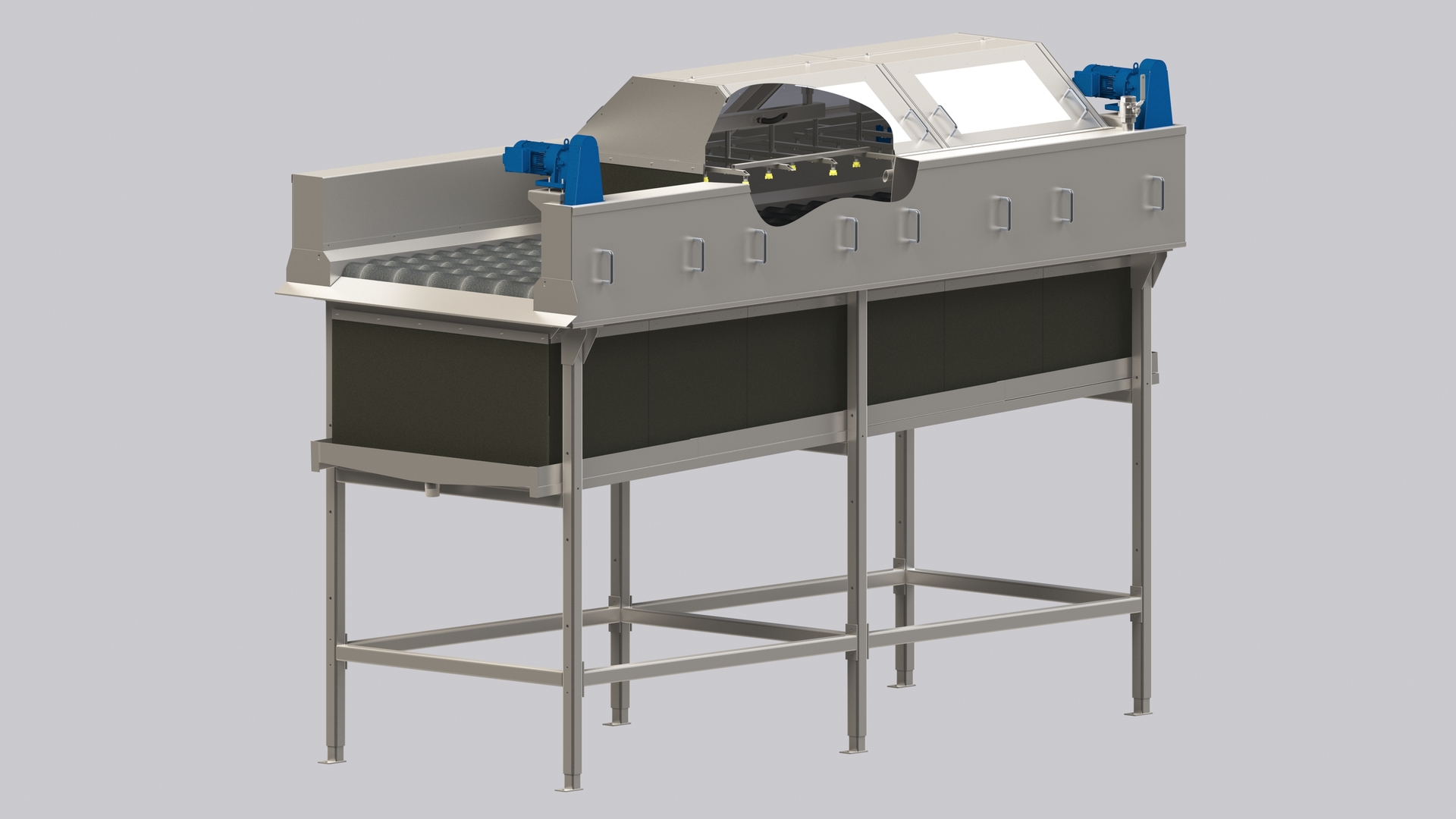

Built for high-throughput washing with minimal downtime for maintenance, the Series 1200 is engineered for efficiency and durability. Available in widths and lengths tailored to your exact needs, the system supports 4″, 5″, or 6″ brush diameters and can be equipped with telescoping infeed conveyors, overhead spray bars, powered brushes, air knives and 400 PSI pressure wash options. Whether configured as a wet washer made with stainless steel or a dry brush unit made in mild steel, its 10-gauge steel frame and square tubing construction ensure long-lasting reliability. Quick-access features like catch pans and product cleanout systems make operation and maintenance smooth — ideal for operations prioritizing speed, cleanliness, and flexibility.

- Telescoping infeed conveyors to delivery product at various points

- Optional powered overhead brushes that articulate up and down over the product

- Overhead Spray bars custom built to your application

- Overhead air knives or circular fans

- Powered product clean out systems

- High Pressure wash systems capable of spraying water at 400 PSI

- Hoods to enclose the unit and contain dust and over spray from nozzles

- Catch pans to capture dirt, mud, and water

- Outstanding reliability

Sizes

Construction

- Made in Exeter, California

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards

Built with fast brush change systems and water or dry configurations, this washer reduces downtime and adapts to your needs. Contact us to explore the best brush setup for your product.