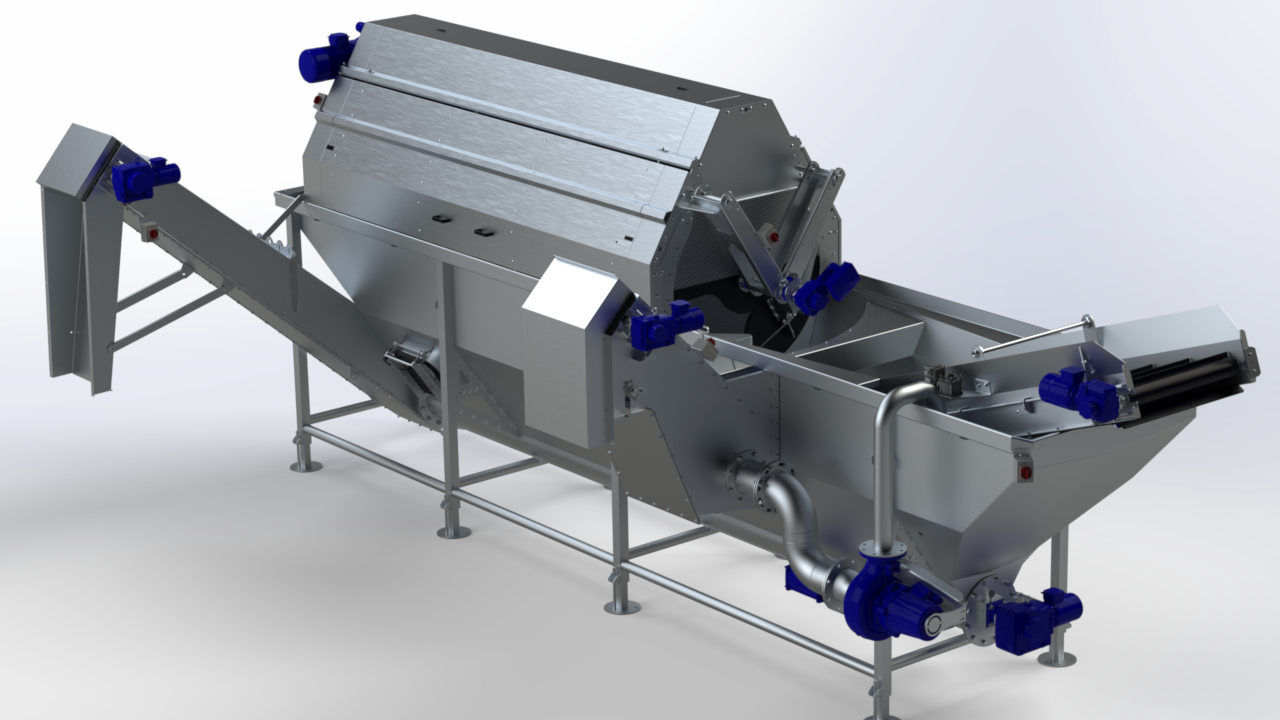

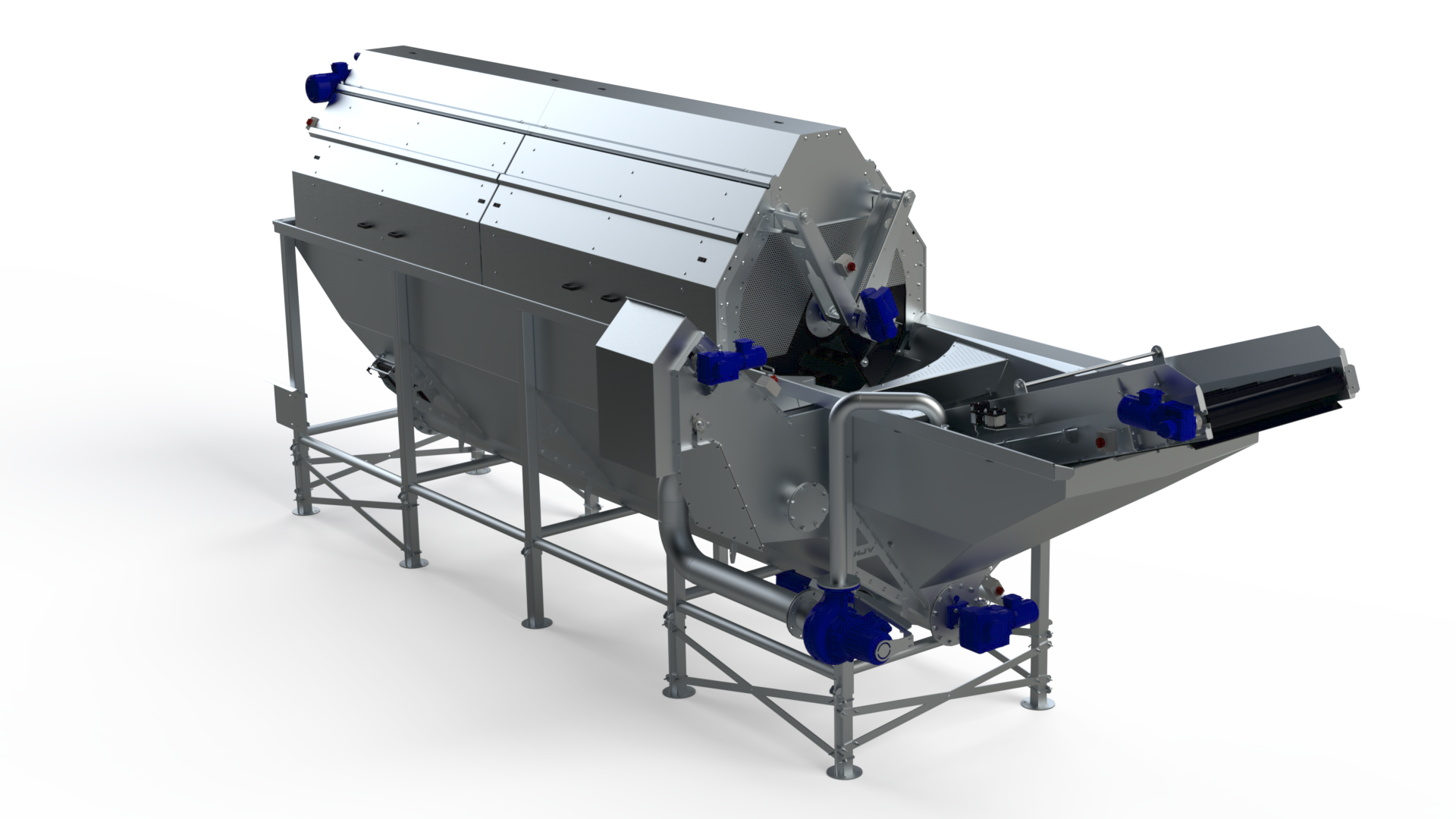

A high-capacity barrel washer that gives you high-volume, gentle cleaning

The Series 1000 Barrel Washer uses a revolutionary design to deliver high volume washing to your lines. The Series 1000 is a high-capacity barrel washer, providing fast, effective cleaning for large volumes of produce while preserving product integrity. It comes in a range of sizes — from 4 meters to 9 meters long — in either 48-inch or 60-inch widths. The Series 1000 can be integrated with up to 12 different lanes. Its quick, auger-based system can clean up to 165,000 lbs per hour. A range of damage reduction features ensure both that speed and product protection go hand-in-hand.

Download Product Brochure

The Series 1000 Barrel Washer features a “pintle” lining. The pintle strips help clean difficult products and barrels can be fully lined or half-lined, depending on your needs. The Series 1000 also uses a unique, smooth surface, with a “D” mold rubber surface. This serves to trap dirt, debris and other foreign objects while maintaining a smooth surface, protecting your product. And the Series 1000 uses an augur system to self-empty. Combined with easy-to-use controls, operators can regulate the amount of water used in cleaning, and the waste discharged, as needed.

The Series 1000 Barrel Washers offer you efficient, effective cleaning without damaging your product. And with a robust, stainless-steel construction and a variety of access doors, the Series 1000 washers are both easy to maintain, keeping your products clean for season after season.

The Series 1000 Barrel Washer is designed for industrial-scale cleaning, with output rates of up to 165,000 lbs per hour, depending on size and configuration. Each unit is built from durable 4mm stainless steel and features full or half pintle lining for optimized scrubbing power. Its “D” mold rubber spiral helps remove debris while cushioning delicate crops, minimizing damage, even at high speeds. Key enhancements include a fresh water rinse bar, gas-assisted access doors and optional spray bars with ozonation for improved sanitation. With optional integrated features like destoners, floating debris removal, and drag chains for waste, this washer is the backbone of high-volume cleaning lines in demanding environments.

- Fresh water rinse bar complete with solenoid valve

- Access doors to barrel equipped with safety locks and gas struts to assist opening

- Electrically operated main door, with remote operation

- “D” mold rubber spiral in barrel

- Access hatches on tank for internal maintenance

- Auger base tank

- Extra optional spray bars available with ozonation

- Available in a variety of barrel widths and configurations

- Integral destoner

- Floating debris removal

- Drag chain for sludge and waste removal

- Special rinse bar

- Brush lining for the barrel

- Full or half pintle lining

- Air assist for floating debris removal

Barrel Sizing and specifications:

4 Meter 1200 (48”)/1500 (60”)

6 Meter 1500 (60”)

Constructed of stainless steel sheet, 4mm thick

Construction

- Made by HJV Engineering in Alliston, Ontario, Canada

- Meets or exceeds all major government and retailer standards

This washer processes up to 165,000 lbs/hour with pintle lining and auger discharge. Designed for large volumes and consistent performance. Contact us to upgrade your washing capacity.