Simple and durable pre-sorting equipment for more efficient sorting lines

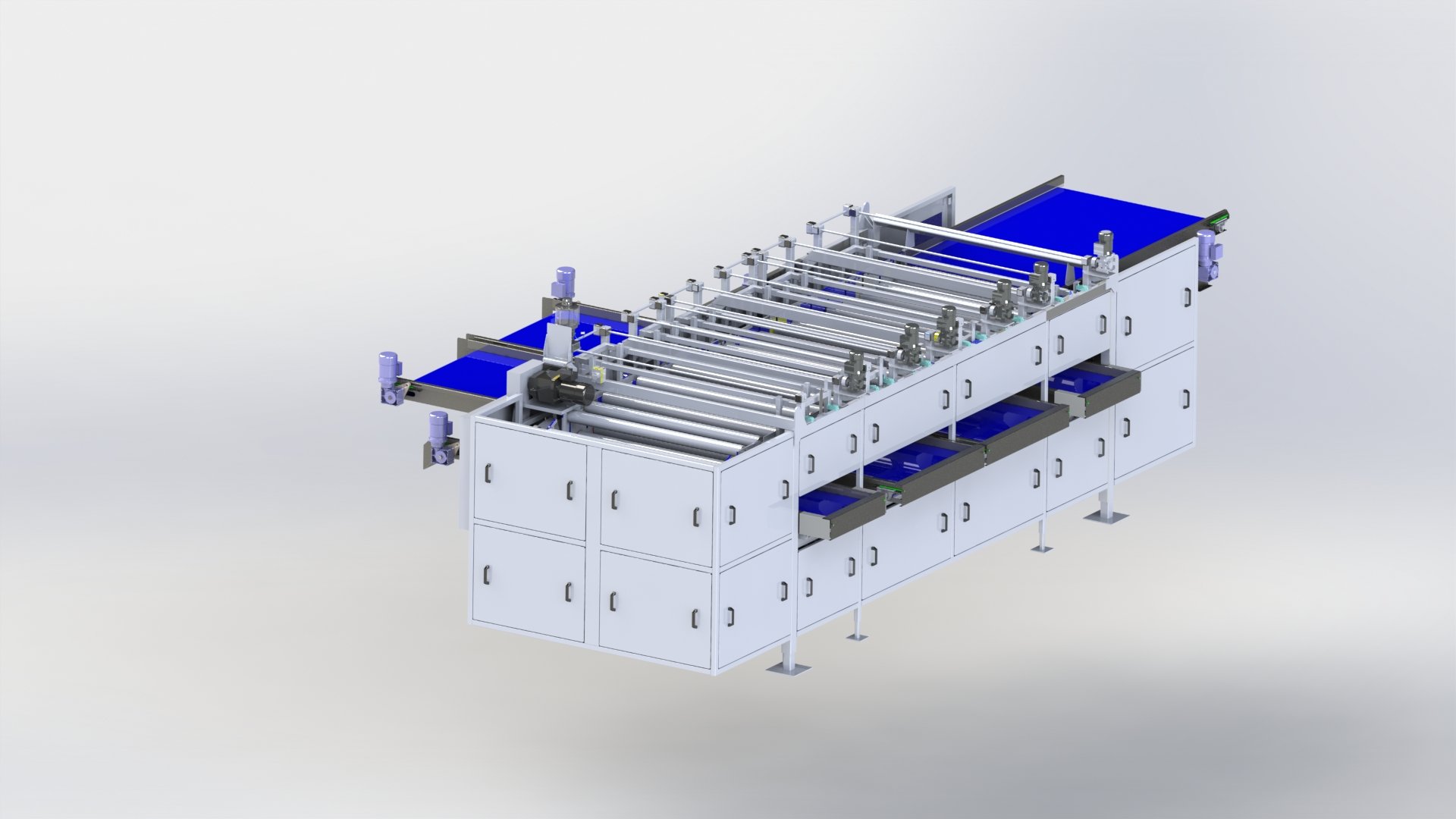

Exeter Engineering’s Screensizers and Undersize Eliminators are two simple solutions to the problem of maximizing the efficiency of your sorting lines. With the ability to control for various sizes of product before they get to your sorter, Screensizers and Undersize Eliminators are easy additions to your lines, saving you time and money. This front-of-the-line sorting equipment enhances your workflow by reducing sorter load and increasing overall throughput.

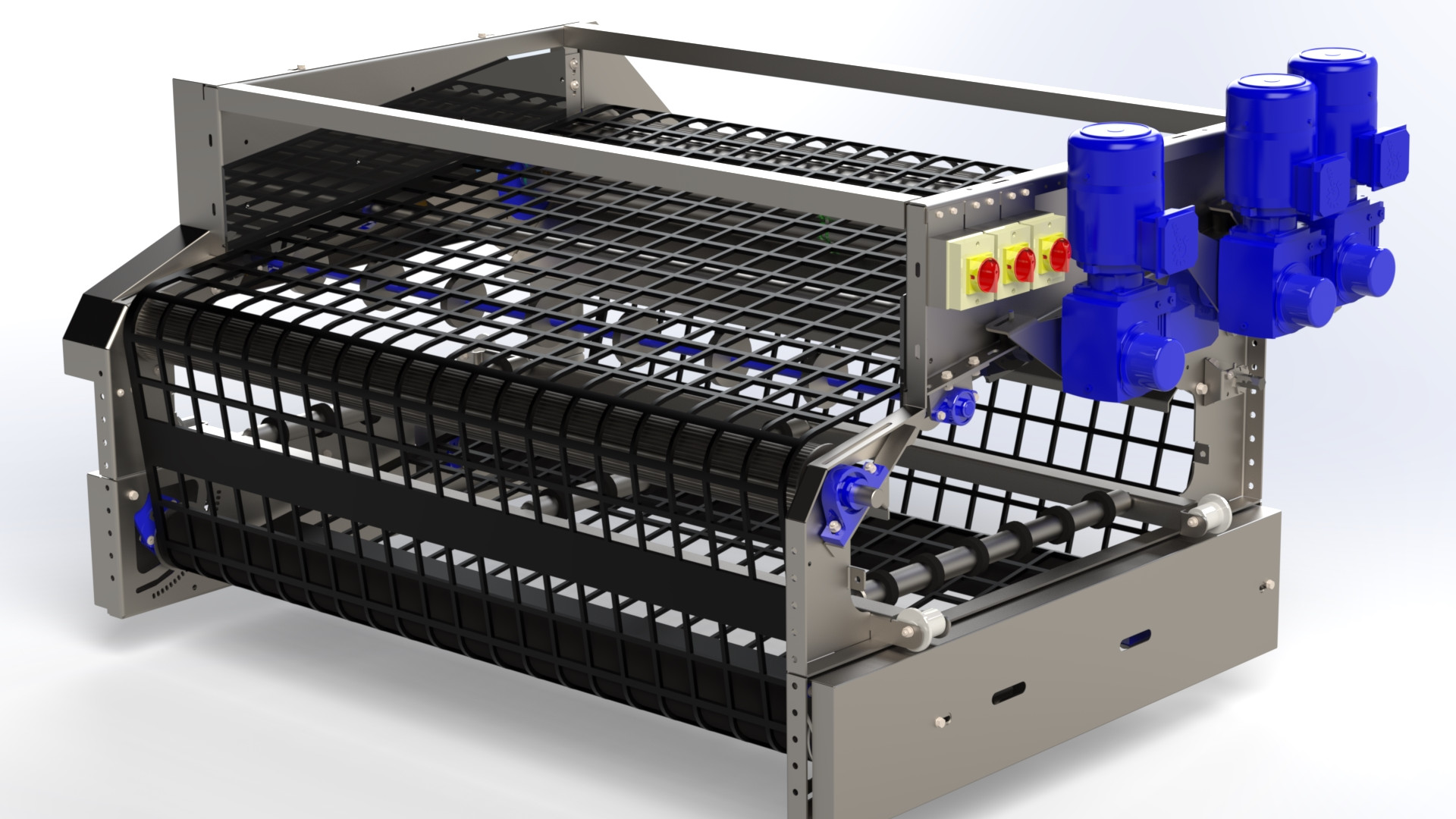

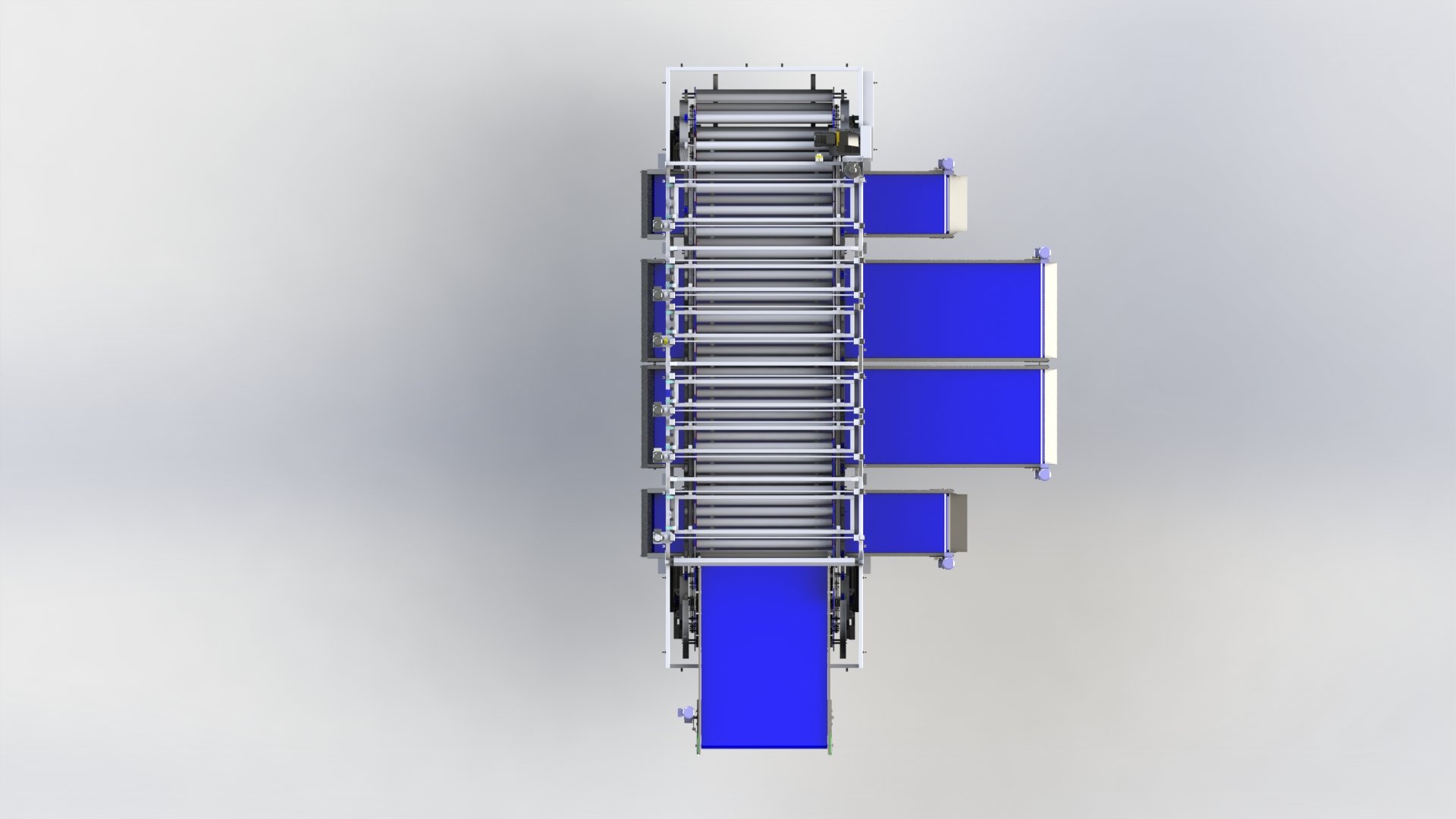

The Exeter Engineering Screensizers and Undersize Eliminators are simple additions to your lines. The Screensizer gives you the ability to change screen sizes to capture various sizes of products before they reach your sorter. From the intake system, the Screensizer allows product to pass over a specially-sized screen on its way to your sorting system. Products that are small enough to fit through the screen openings fall through and are gathered in the collection system. The rest of your product proceeds to sorting. The system reduces the number of passthroughs and increases the efficiency of your sorting.

The Undersize Eliminator is a fixed size (height and width) screen that captures any undersized product passing over it. While the remainder of your product goes to sorting, the undersized is gathered in the collection system. Whether you need the flexibility of multi-sizes or the certainty of a fixed-size, our Screensizers and Undersize Eliminators offer you simple solutions.

Screensizers and Undersize Eliminators are engineered to boost throughput by separating undersized product before it reaches your primary sorter. The Screensizer offers flexibility with changeable screen sizes, allowing custom calibration for specific crop types and size thresholds. The Undersize Eliminator, built for set sizing, delivers maintenance-free operation while still ensuring accurate removal of small product. Both are constructed with food-grade 304 stainless steel and are compatible with Exeter’s leading sorters—including the AccuVision360, AccuVision, Sidewinder and Oculus. With minimal maintenance needs, easy cleaning and rugged design, this equipment integrates seamlessly into any line while supporting regulatory and retail compliance across industries.

- Screensizer: easy-to-change screens of varying sizes

- Undersize Eliminator: no-maintenance elimination of undersized product

- Easy to clean

- Rugged construction, lasting for season after season

- Can be combined with the AccuVision360, AccuVision, Sidewinder or Oculus sorting systems

Construction

- Screensizer is made by HJV Engineering of Alliston, Ontario, Canada

- Undersize Eliminator is made in Exeter, California

- Undersize Eliminator carries a 24-month warranty

- Both made with 304 stainless steel; different grades are available

- Undersize Eliminator uses electrical components by Allen Bradley; other marks available

- Both meet or exceed all major government and retailer standards

These pre-sorting systems efficiently remove undersized or oversized produce before it reaches your main sorter. Built for durability and easy cleaning, they improve line speed, reduce waste, and support downstream equipment. Contact us to integrate Screensizers into your existing setup.