High-capacity performance in an automated collating and baling system

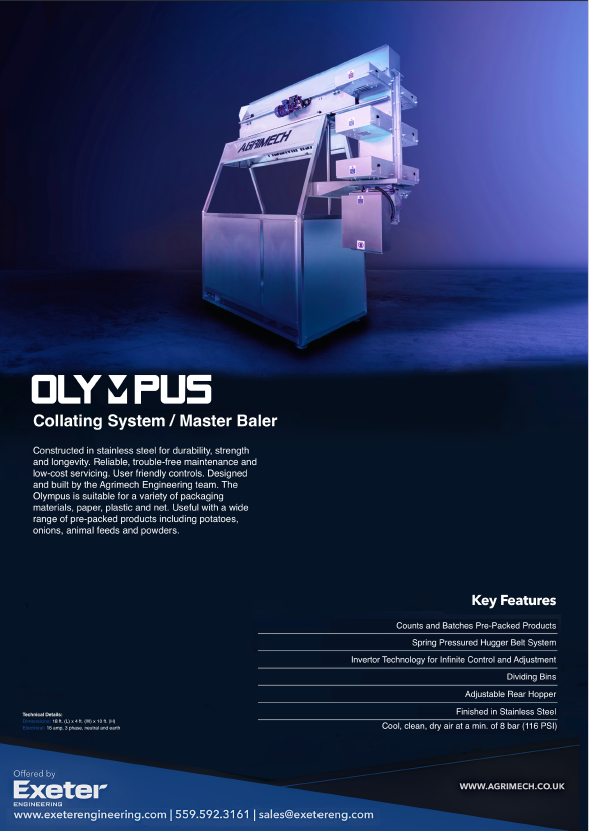

The Olympus Collating System–Master Baler is a highly capable solution for gathering product and readying it for consolidated packaging. As an automated collating and baling system, the Olympus delivers precision, speed and durability for streamlined master packaging across a range of fresh produce packaging types. Olympus can quickly and reliably count and batch pre-packed products and is suitable for a number of packaging materials, including paper, plastic and net. Like all of the Agrimech products we offer, the Olympus is designed and engineered to last: stainless steel construction throughout guarantees a durable, strong and long-lasting partner for your collating and baling needs. The Olympus is easily operated and maintained and, despite its many abilities, is available at a price point you won’t believe.

Download Product Brochure

The Olympus collating–master baling system is automation at its finest. The Olympus is built to gather and dispatch pre-packaged product as precisely as you need it into paper, plastic or net containers. With an adjustable rear hopper, a spring-pressured hugger belt-system and invertor technology, your pre-packed product will be gently collated and deposited in the precise amounts you specify into your master packaging. The Olympus works well with paper, plastic or net sacking and is useful for a variety of products, ranging from produce like potatoes or onions, to smaller loose product…even powders.

Like all of the Agrimech products we offer, the Olympus is both easy to use and built to last. Olympus uses intuitive user controls and offers precise adjustments when you need them. It’s also easy to maintain, with a simple design, stainless steel construction and standard components. Easy to integrate with other Agrimech products or as part of a more complete line, Exeter Engineering is happy to offer you this great collating–master baling system.

The Olympus system is built for precision batching of pre-packed goods into master packaging formats such as sacks or cartons. Its spring-pressured hugger belt and dividing bins gently manage products like potatoes, onions or loose goods such as feed and powders — ensuring both protection and efficiency. With inverter-controlled speed adjustment and an intuitive control interface, Olympus allows seamless customization of fill settings to meet your production goals. Constructed entirely from stainless steel and powered by standardized electrical and pneumatic systems, it’s easy to maintain, highly reliable and integrates effortlessly into larger automated packing lines. Olympus is the high-throughput solution for businesses that demand both flexibility and long-term performance.

- Invertor technology, for infinite control and adjustment abilities

- Spring-pressured hugger belt-system

- Dividing bins

- Adjustable rear hopper

- Useful across a wide range of pre-packed product, including potatoes, onions, and loose product (like feeds or powders)

- Min. of 8 bar (116 PSI) clean, cool, dry air

- Stainless steel construction

- Electrical: 16 amp, 3 phase, neutral and earth

- Standardized components for easy maintenance and maximum up-time

Construction

- Made by Agrimech in Three Holes, Norfolk, UK

- Meets or exceeds all major government and retailer standards

The Olympus collating and baling system efficiently gathers pre-packed goods into master packaging. With variable hopper options, hugger belts, and intelligent batching, Olympus boosts speed and accuracy. Contact us to automate your batching process.