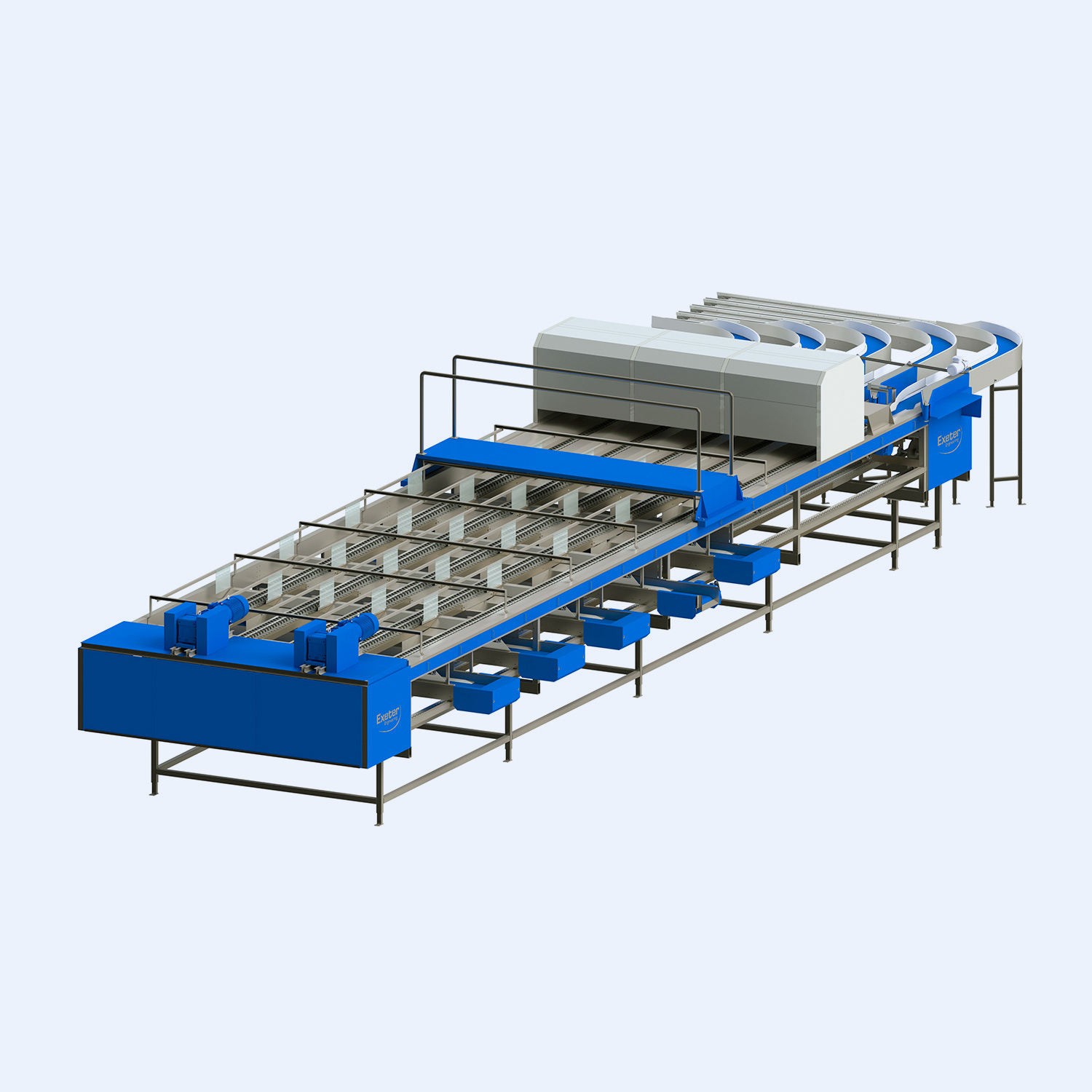

Fast and accurate, the AccuVision XL melon sorting machine is built for high-volume melon packing operations

The AccuVision XL is designed specifically for large melons and round melons. As a purpose-built melon sorting machine, it offers reliable performance and gentle handling across all packing environments. Fast and delicate, the AccuVision XL guarantees your throughput will stay high. Using Exeter Engineering’s exclusive ID Technology, the AccuVision XL gives you optimal sorting results by weight, shape, size or external defects. And the AccuVision XL is built tough, ready to handle the rigors of the job, season after season.

Download Product Brochure

AccuVision XL sorters are designed to sort large seedless and seeded melons. With a high capacity and a labor-free, automatic infeed system, melons are gently delivered to the sorter and processed quickly and efficiently.

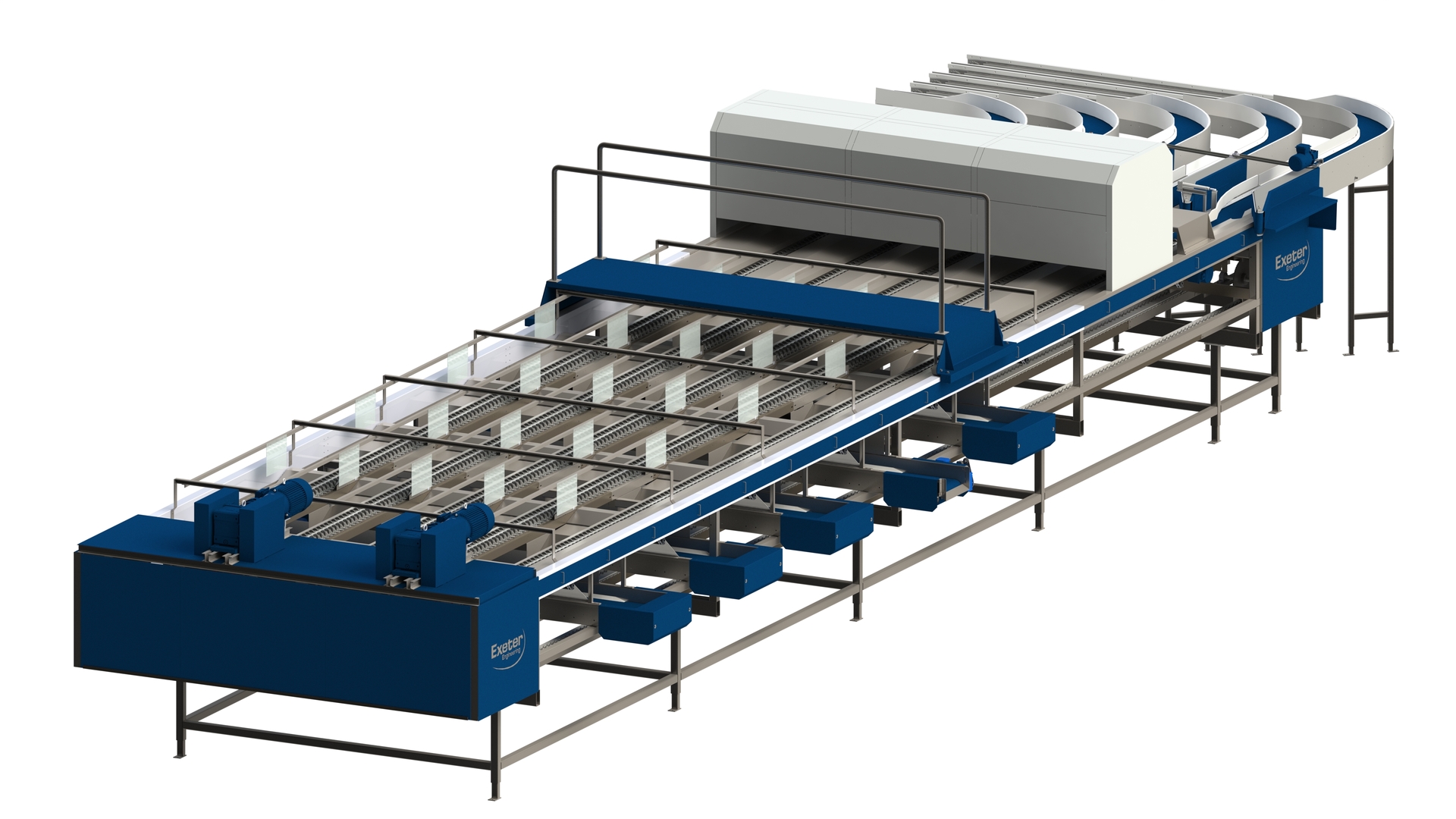

Exeter Engineering’s exclusive ID Technology system provides optimal sorting results. Using high-definition, multispectral cameras mounted at opposing 45-degree angles and custom-tuned LED lighting, the AccuVision XL’s ID Technology suite takes multiple high-resolution images of each piece of product in both visible and infrared spectrum. These images are used to calibrate weight, shape, external color and surface characteristics.

ID Technology’s easy-to-use software makes it simple to select or change grades. And with ID Technology’s live imagery, intuitive controls and built-in “predictive change” capability, you can see — in real time — how the changes you are thinking of making will affect your grading going forward.

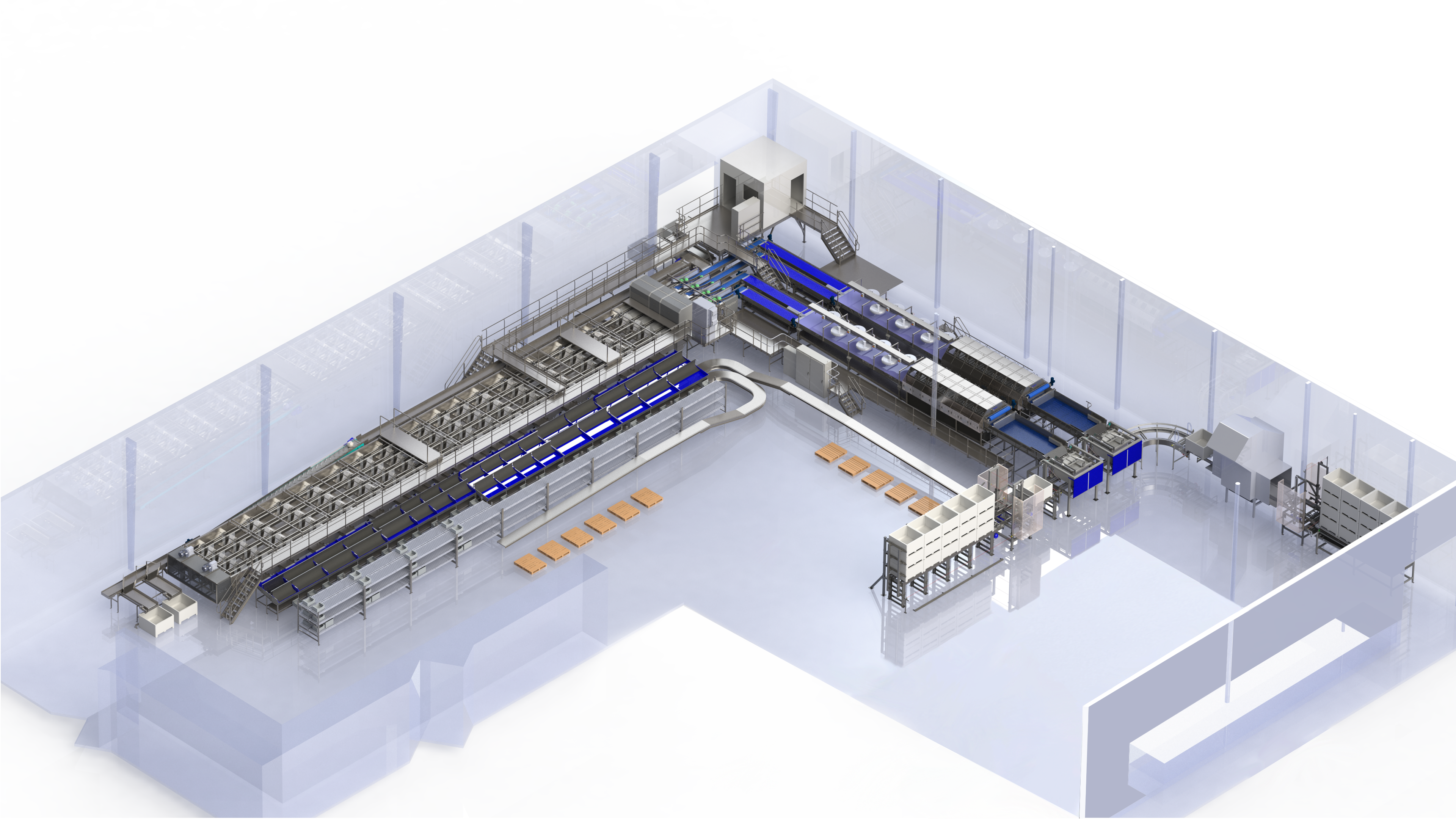

The AccuVision XL can be installed as a mobile, stand-alone unit or as part of a permanent line. Exeter Engineering offers complete pack line design solutions for receiving your melons from the field to the packing house — from product reception areas receiving product in bulk or bins, to washing and automatic tri-wall fillers. There’s a reason we are still called “Exeter Engineering”: we don’t just make or install equipment, we build solutions.

With the ability to process up to 60,000 pounds of product per hour, the AccuVision XL delivers exceptional performance for large-scale melon operations. Its automatic singulation system ensures smooth, labor-free loading, while the durable plastic carrier transport and pneumatic ejection system provide soft, damage-free handling. The integrated ID Technology uses multispectral HD cameras and custom-tuned LED lighting to capture real-time images for grading by size, shape, weight, and surface defects. Designed for flexibility, the AccuVision XL can be deployed as a mobile unit or seamlessly integrated into a full-scale packing line with optional tri-wall fillers. Built with food-grade stainless steel and using Allen Bradley components, it meets all government and retailer standards—providing long-term reliability season after season.

- High volume: up to 30 tons per hour

- Automatic singulation

- Customizable drops

- Accurate sorting by dimensions, shape, size and/or weight

- ID Technology package, with custom-tuned lighting in visible and infrared spectrum and high-definition, dual camera system

- Reliable plastic melon carrier transport system

- Pneumatic ejection system for gentle handling

- Padded pack tables

- Easily paired with our Melon Tri-Wall Fillers

Capacity (lbs/hr)

Products

Grading features

Construction

- Made in Exeter, California

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards

The AccuVision XL melon sorting machine delivers high-speed, gentle, and highly accurate grading for large round melons such as cantaloupes or watermelons. Designed with AI-powered technology and built for heavy-duty performance, it ensures consistent results while minimizing product damage. Ideal for operations focused on both throughput and quality, this solution adapts to your packing line with ease. Contact us to discuss the right configuration for your operation and how the AccuVision XL can improve your efficiency.