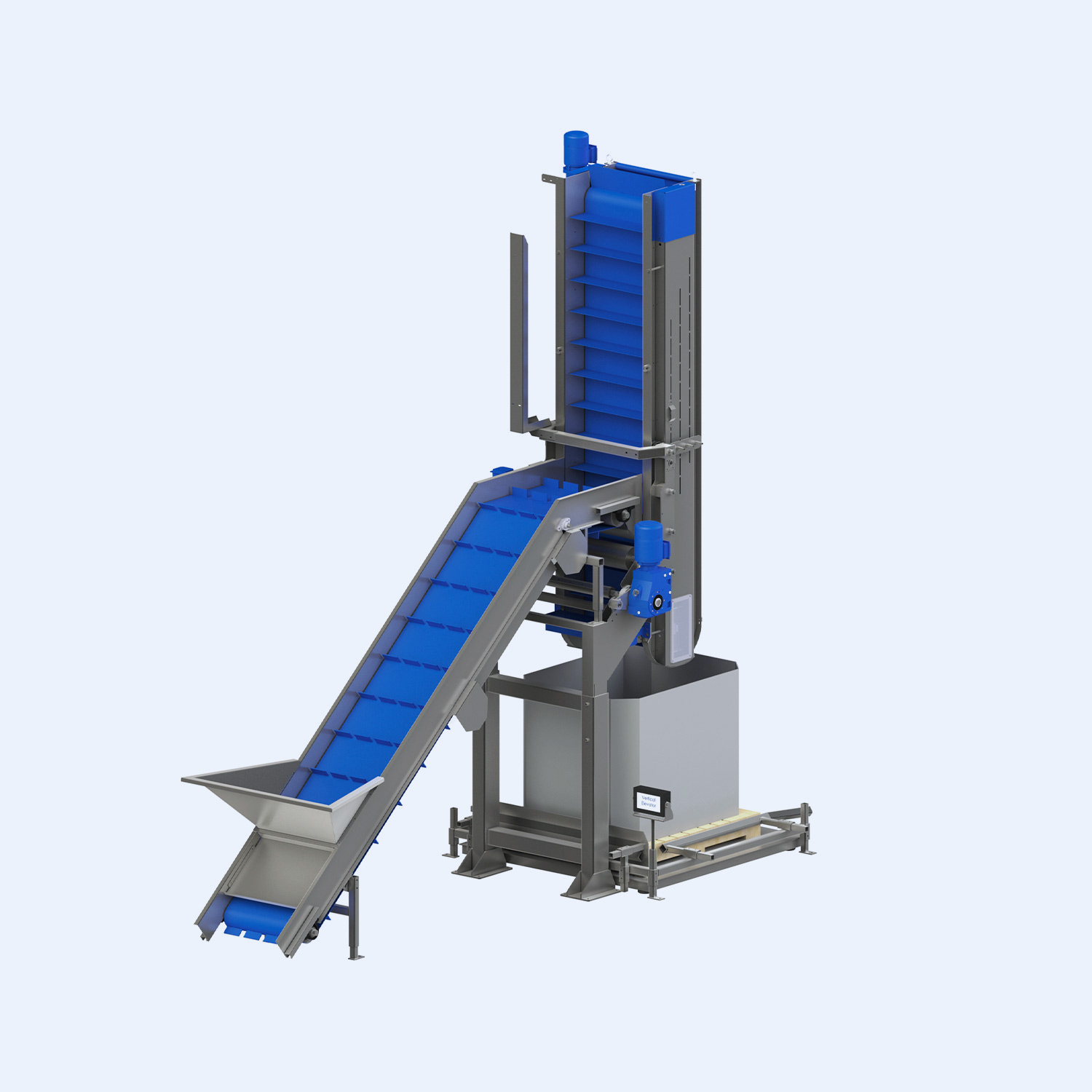

Flexible filling of bins, tri-walls, and totes with a versatile tote and bin filling system

Exeter Engineering’s AccuTote Lowerating Tote Filler systems are designed to work on more than just totes. You can use the AccuTote with a variety of different sized bins, tri-walls and, of course, totes. The AccuTote is gentle, accurate and flexible. It is available as either a standalone single unit or associated with automated bin infeed systems in multiple units. The AccuTote is the versatile tote and bin filling system for you to ensure accurate, gentle placement for a range of produce that reduces labor and maximizing throughput.

The AccuTote Lowerating Tote Filler are designed to offer you the flexibility you need and the gentle product handling you require. With the ability to gently, evenly, and accurately fill a variety of packaging types, the AccuTote will work with your bins, tri-wall containers and totes.

The AccuTote can be configured as a standalone unit or installed as part of a bank of two or more units with central control. Our intuitive software and touch-screen controls makes using the AccuTote quick and easy, whether that’s controlling a single unit or a bank of twelve from a single control unit.

Exeter Engineering’s AccuTote can be integrated with scales to capture weights and alleviate the extra step of removing bins or totes to weigh them. They can also be equipped with our empty-bin or tri-wall fill systems. Once filled the bins, tri-walls or totes are filled, they can be stacked and sent to a common set-off conveyor, increasing your operational efficiency and reducing your labor costs.

AccuTote is purpose-built to fill bins, tri-walls and totes with minimal drop height—reducing bruising and ensuring even product distribution. Its adjustable vertical travel adapts to the specific container height, making it ideal for diverse packing operations handling potatoes, onions, sweet potatoes or citrus. Whether installed as a single filler or a multi-unit configuration with centralized controls, AccuTote is designed for high reliability and low operational cost. Integrated scale options streamline the weighing process, while optional automated infeed and discharge systems improve efficiency. Constructed with durable 304 stainless steel and using Allen Bradley components, the AccuTote is built to meet industry standards and handle season-after-season demands with ease.

- Easy-to-use, with an intuitive UI and touch screen controls

- Robust design

- Outstanding reliability

- Low operating cost

- Works with a variety of bins, tri-walls and totes

- Automated infeed and discharge options for bins and tri-walls

- Gentle product handling with minimal drop distance from bottom

- Even fill of product

- Scales can be integrated as an option.

Sizes

Products

Construction

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards

The AccuTote is built to fill bins, totes, and tri-walls gently and efficiently. With vertical travel adjustment, touch-screen controls, and optional automation, it’s designed to adapt to your operational scale. Contact us to discuss how AccuTote supports your throughput goals.