Potato

Challenge Exeter Engineering was asked to design and build a complete fresh pack line for a potato grower/packer in Central California. The client's major goals were automation and keeping the labor cost to a minimum.

The line was to be designed for packing a small potato variety with a minimum diameter of 3/8 inch to a maximum of 2 inches. This variety comes in several colors, including yellow, red, and purple, making the sorting challenging.

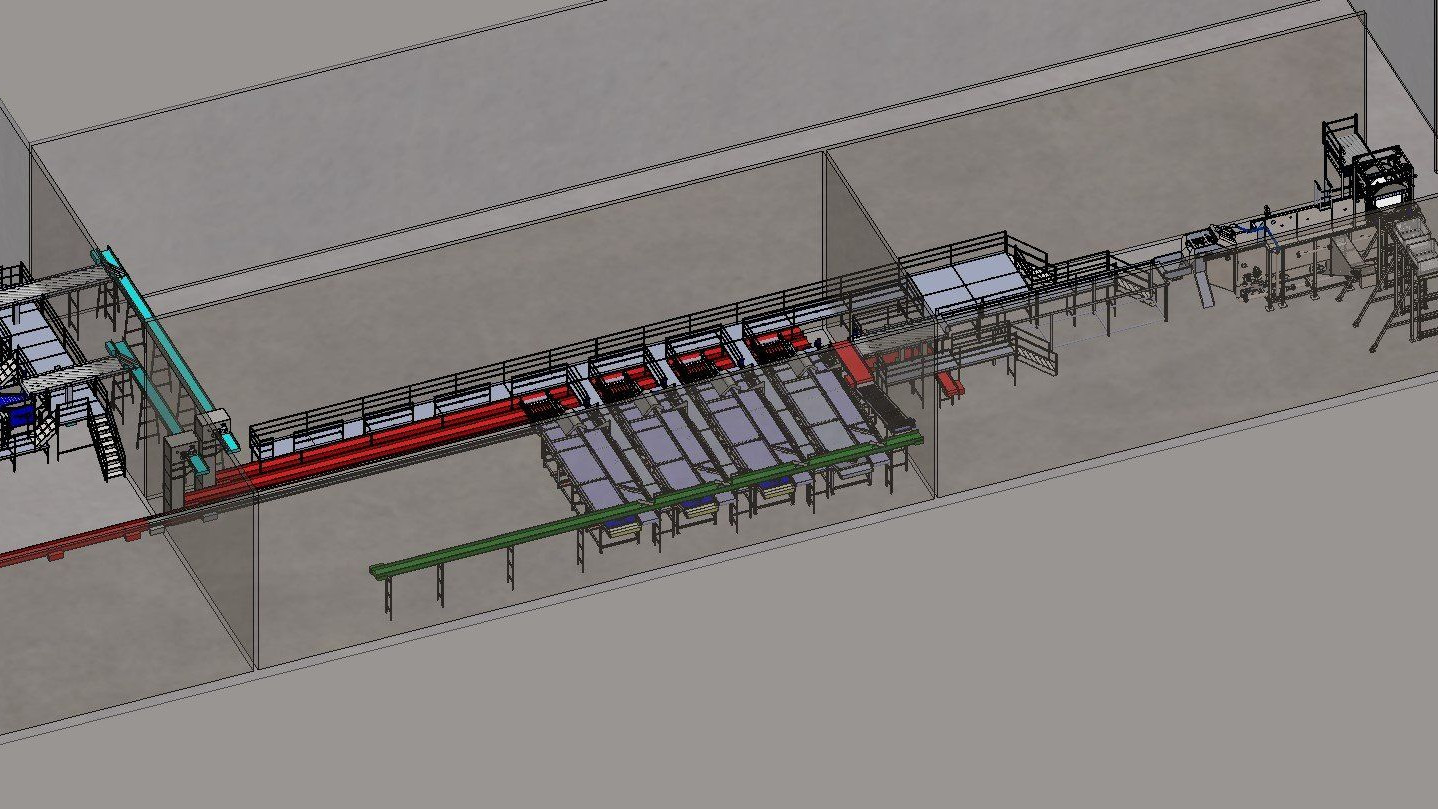

As this was for a complete line, the client wanted everything from inflow to packaging. The client’s design requirements called for the ability to wet dump 60 bins per hour (60,000 -72,000 pounds per hour), wash, grade, and then move the product to 8 accumulation bins. Once the product was accumulated in the bins, 2 bagging systems would then call for product as needed.

Solution

After getting to know the client, their needs, and the space in which the line was to be housed, we decided to begin the line with our XTR 200 Auto Bin Dumper (in rotary configuration). This allowed the client to lower their product bins into one of our Series 4000 Wet Reception Tanks at the rate of 60 bins per hour. The Series 4000 tanks provided a great pre-soak and allowed heavy sentiments to settle at the bottom, where they were removed by the automated auger system.

From there, the potatoes were moved into our Series 1000 Barrel Washer where they were rinsed and then were treated with OZONE. After that, the line led to a sorter, chosen by the client, which met their needs. The graded potatoes were then moved a shear belt to move on towards packing. We used an Exeter Engineering XTR 100 4-Belt Accumulator to collect the potatoes from the sheer belt. The XTR 100 was set-up in a first-in, first out (FIFO) configuration, ensuring that the oldest potatoes are called out first by the baggers to minimize storage time and keep the potatoes fresh for the consumer.

From the XTR 100 4-Belt Accumulator system, we routed the potatoes to two Exeter Engineering Series 8500 Vertical Elevators, which raised them up for the next portion of the line. Once there, the potatoes passed over a grade table for a final inspection before being packaged. The potatoes were routed through our XTR 300 EvenFlow Hoppers to maintain a steady and continues flow to the baggers without having to stop the grade lines.

The entire system is PLC controlled from start to finish, allowing operators to control the system from either the main panel touch screen or from a second, remote control pad.

Result

The new line was inaugurated several years ago and has been running without issue ever since. The client has reported that it runs with minimal staff, reducing their labor costs, while still meeting all their initial objectives.