Five Crowns Marketing - honeydews and mixed melons

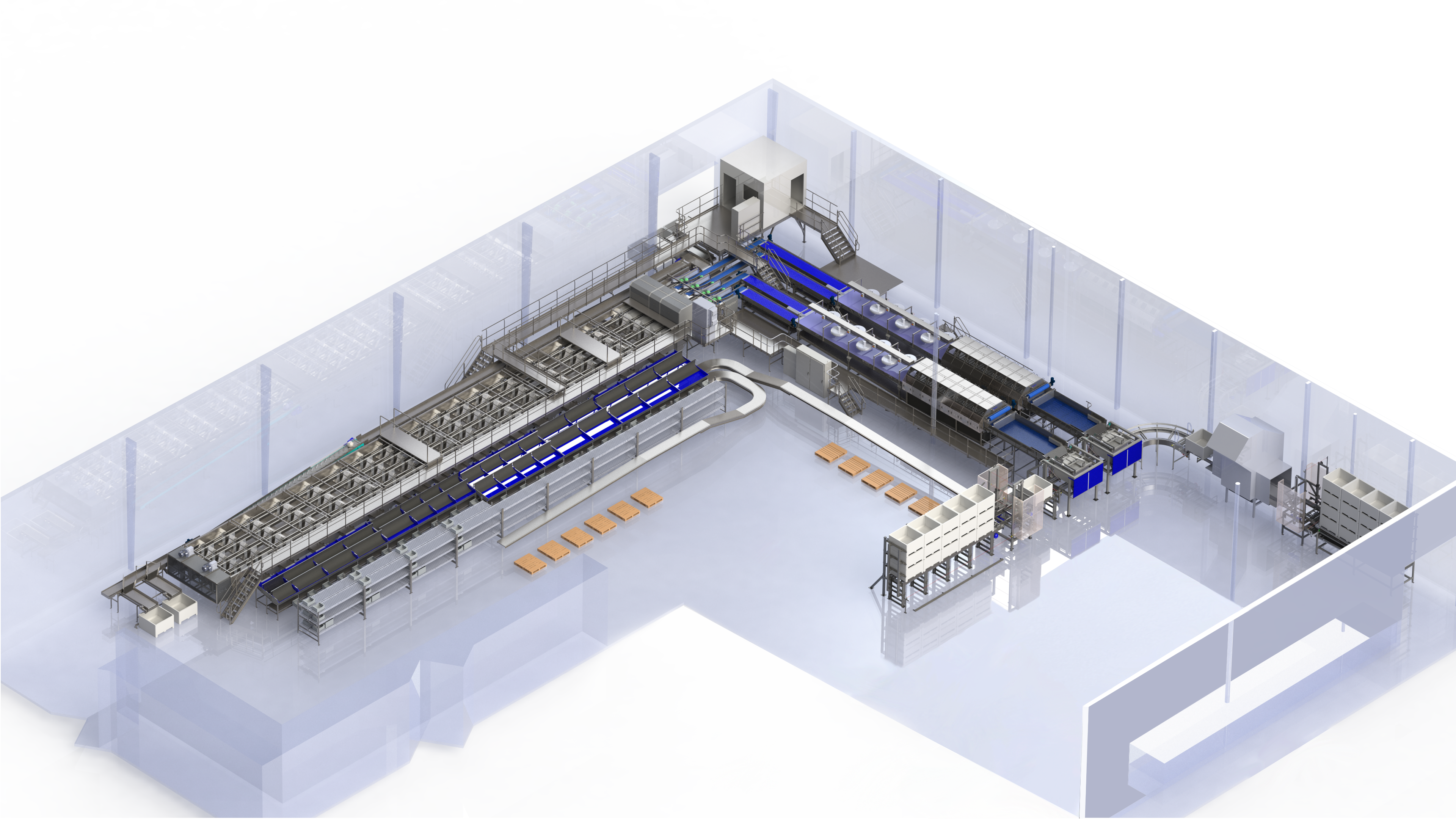

Challenge Exeter Engineering was asked by our friends at Five Crowns Marketing to design a new line for honeydew and mixed melon. The line needed to handle a volume of 140 bins per hour, with each bin weighing around 40 pounds and containing an average of 26 melons.

Five Crowns uses plastic field bins (Macro 26A) and needed a line that could handle the requested volume from receiving, through grading, to packing tables where the melons will be packed by hand. The new line was required to replace an existing line that lacked the grading and throughput capabilities Five Crowns needed to continue to develop their business and meet their own customers’ needs.

Solution

Bins arrive at the receiving point stacked three high. Exeter Engineering installed a pair of XTR200 Auto Bin Dumpers to gently empty the Macro 26A bins onto an EE003 Roller Sorting Conveyor system. Each dumper feeds a separate cleaning line. The product is then conveyed through a Series 1200 Horizontal Brush Washer. Each of the Series 1200 washers has 3 sets of individually controlled spray manifolds, allowing for more precise adjustments and maximum dirt and debris removal. The Series 1200 variants also use ringer rolls at the end of the cleaning chamber. Combined with large, overhead blowers, these rolls dry the product before inspection and grading for better results.

While the product is being washed, the plastic field bins are rinsed and stacked. They are then stacked four-high by a single forklift operator and ready for re-use.

When the washing process is complete, the product moves to pre-grade and debris removal. Five Crowns personnel conduct a manual check at installed grade tables where each table can accommodate up to four graders, as needed.

Once the trash and obviously defective melons are removed, conveyors take them to the new AccuVision XL, using our plastic melon carrier transport system. This installation is designed to run at a speed of 3,600 cartons per hour at a 33% fill rate and at a speed of 200FPM. The AccuVision XL used here features 4 lanes, with receiving/washing/grading line feeding two of the lanes. This gives the allows our customer to run only two lanes, if volumes are low or there is an issue with any portion of one of the lines, offering both flexibility and redundancy.

The AccuVision XL uses our ID Technology — Exeter Engineering’s industry-leading AI-powered optical grading suite of cameras, custom-tuned LED lighting, and algorithmic sorting. ID Technology automatically sizes and grades the mixed melons and honeydews, using parameters set by the customer’s staff. Once sorted, the product is pushed to drops which feed hand-pack tables. ID Technology uses a custom database developed for the customer’s honeydews and mixed melons. This install represents the first AI-powered grading of that type of honeydews and mixed melons ever available on the market.

After sizing and grading, the Five Crown’s personnel hand pack the product into open top boxes. These boxes are then placed on a EE001 Belt Conveyor System and transported to the hand-stacking station, where they are palletized for onward delivery to the ultimate customer.

Result

Five Crowns Marketing reports that the new packing line has substantially improved sizing and grading consistency and accuracy. They are particularly pleased with ID Technology’s results, and the ability to adjust grading during the sort and see what those adjustments will mean across the entire run. With product sizes ranging from 4-9” in diameter, with a piece size of 6.5” in diameter, the boxes Five Crowns provides downstream are filled faster — up to 140 bins per hour — and with almost no variation. The AccuVision XL sorting system increased the Five Crown’s sorting flexibility and offered them the security of two independent lines with equal speed and accuracy.

Watermelon

Challenge Exeter Engineering was asked to design a packing line for watermelons. The customer requested a line that could handle an incoming volume of 120,000 lbs per hour. The watermelons would be arriving at the facility in field bins of 900 lbs. each and needed to be gently dumped from those bins at a rate of 133 bins per hour, before washing, grading and repacking into tri-wall containers.

Solution

Exeter Engineering utilized a pair of XTR200 Auto Bin Dumpers to gently empty the field bins onto an EE003 Roller Sorting Conveyor system. The watermelons were conveyed to a manual inspection station, where staff removed any trash or obviously defective watermelons. From there, the conveyors took the watermelons to a pair of Series 1300 Linear Brush Washers to clean the melons before grading.

We installed a pair of AccuVision XL sorters to handle the required volume and meet the customer’s quality goals. These sorters were fitted with 8 powered drop points on each sorter. Using the AccuVision XL’s ID Technology suite of multi-spectral, high-definition cameras and custom-tuned LED lighting, the customer was able to sort for dimensional size, calibrated weight, shape, color and external quality. Melons were sent to the appropriate drop point, based on the AccuVision XL’s grading decision.

After sorting, the watermelons were sent for packing in Tri-Wall containers containing 700 lbs. of product each. We used our Melon Tri-Wall Fillers to automatically fill the containers. The Melon Tri-Wall Filler uses an automatic feed system to gently and evenly place the melons within the Tri-Wall container. Once filled, the full containers were visually inspected and then conveyed to cold storage to await onward shipment to the customer’s clients.

Result

The customer reports that the new packing line dramatically improved product handling and washing. The AccuVision XL sorting system increased the client’s sorting accuracy, flexibility and product utilization. The end result was an increase in throughput of over 200%, with a decrease in labor costs of 30%. The volume packed per person went from 3,000 lbs. per hour, per person to over 7,000 lbs. per hour, per person.