Challenge Exeter Engineering was asked to design a packing line for watermelons. The customer requested a line that could handle an incoming volume of 120,000 lbs per hour. The watermelons would be arriving at the facility in field bins of 900 lbs. each and needed to be gently dumped from those bins at a rate of 133 bins per hour, before washing, grading and repacking into tri-wall containers.

Solution

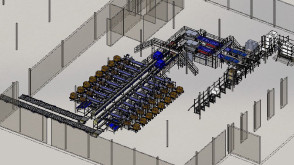

Exeter Engineering utilized a pair of XTR200 Auto Bin Dumpers to gently empty the field bins onto an EE003 Roller Sorting Conveyor system. The watermelons were conveyed to a manual inspection station, where staff removed any trash or obviously defective watermelons. From there, the conveyors took the watermelons to a pair of Series 1300 Linear Brush Washers to clean the melons before grading.

We installed a pair of AccuVision XL sorters to handle the required volume and meet the customer’s quality goals. These sorters were fitted with 8 powered drop points on each sorter. Using the AccuVision XL’s ID Technology suite of multi-spectral, high-definition cameras and custom-tuned LED lighting, the customer was able to sort for dimensional size, calibrated weight, shape, color and external quality. Melons were sent to the appropriate drop point, based on the AccuVision XL’s grading decision.

After sorting, the watermelons were sent for packing in Tri-Wall containers containing 700 lbs. of product each. We used our Melon Tri-Wall Fillers to automatically fill the containers. The Melon Tri-Wall Filler uses an automatic feed system to gently and evenly place the melons within the Tri-Wall container. Once filled, the full containers were visually inspected and then conveyed to cold storage to await onward shipment to the customer’s clients.

Result

The customer reports that the new packing line dramatically improved product handling and washing. The AccuVision XL sorting system increased the client’s sorting accuracy, flexibility and product utilization. The end result was an increase in throughput of over 200%, with a decrease in labor costs of 30%. The volume packed per person went from 3,000 lbs. per hour, per person to over 7,000 lbs. per hour, per person.