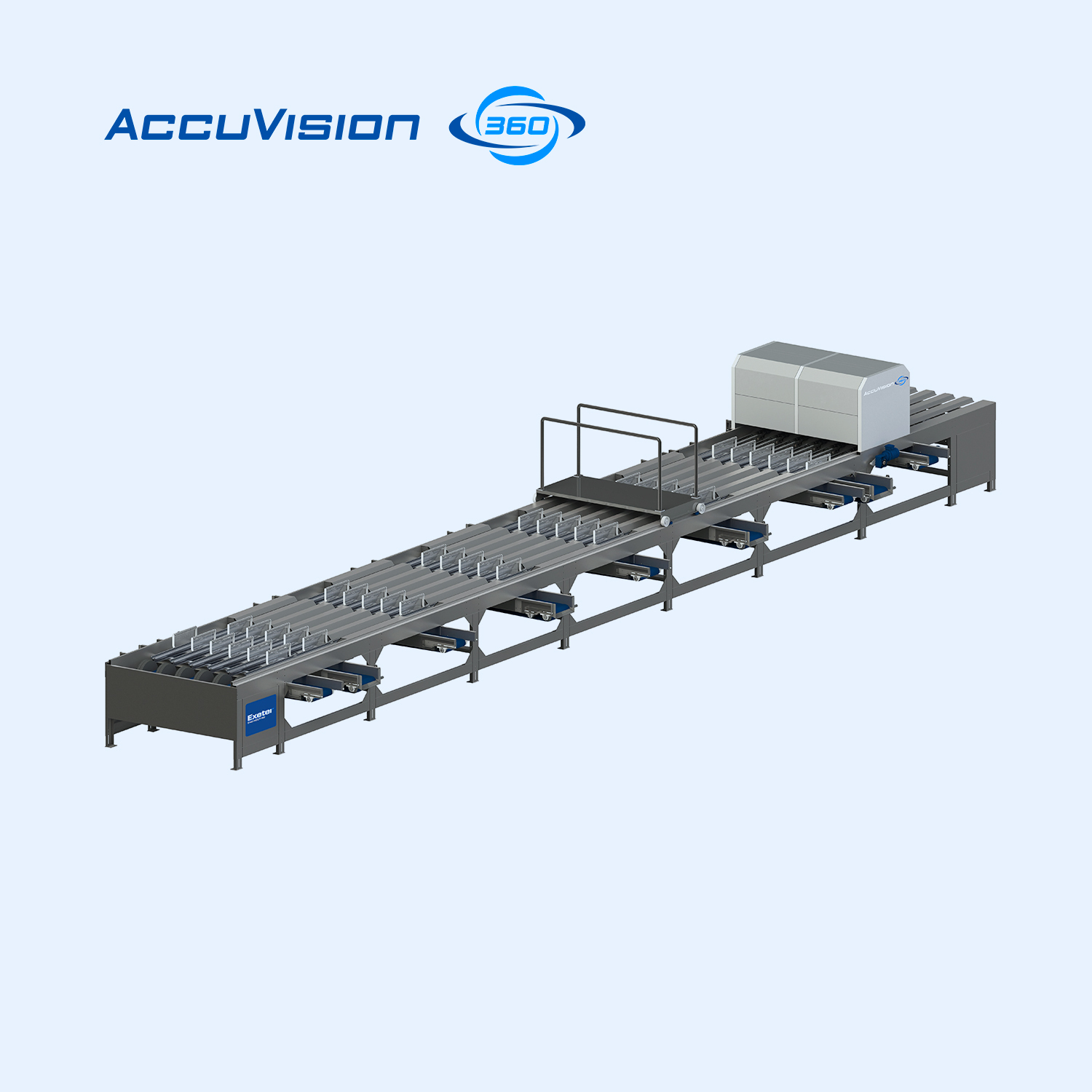

The revolutionary high-speed produce optical sorting machine with unmatched accuracy and speed

The AccuVision 360 is our newest, most accurate multi-drop sorter for use on oblong-shaped produce. With a revolutionary presentation system and rugged construction, this machine offers high-quality sorting at incredible speed… and at the lowest operating costs in the industry today. As a high-speed optical sorting machine for fresh produce, it’s engineered for precision and productivity — processing more product in less time without compromising quality.

Download Product Brochure

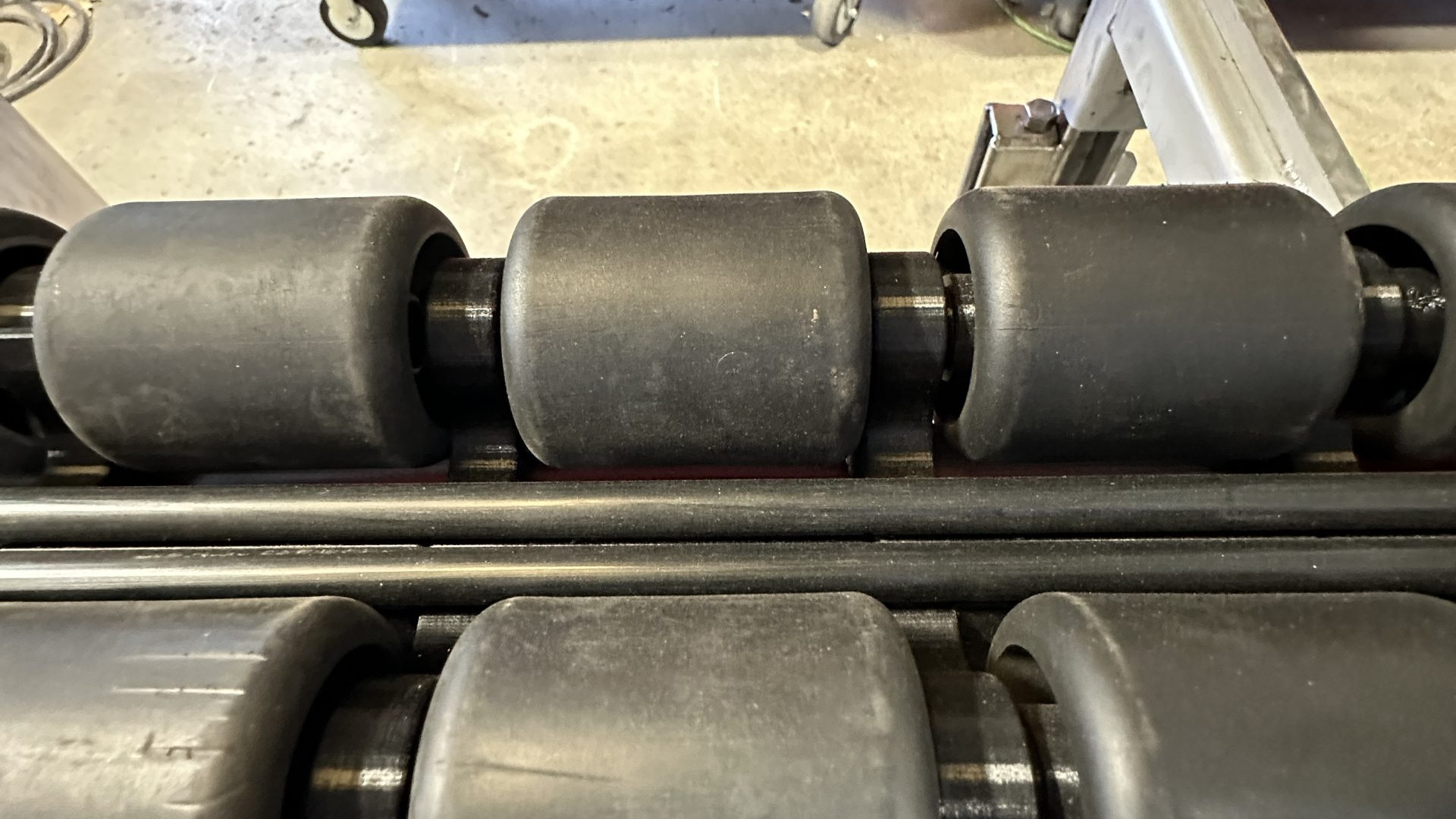

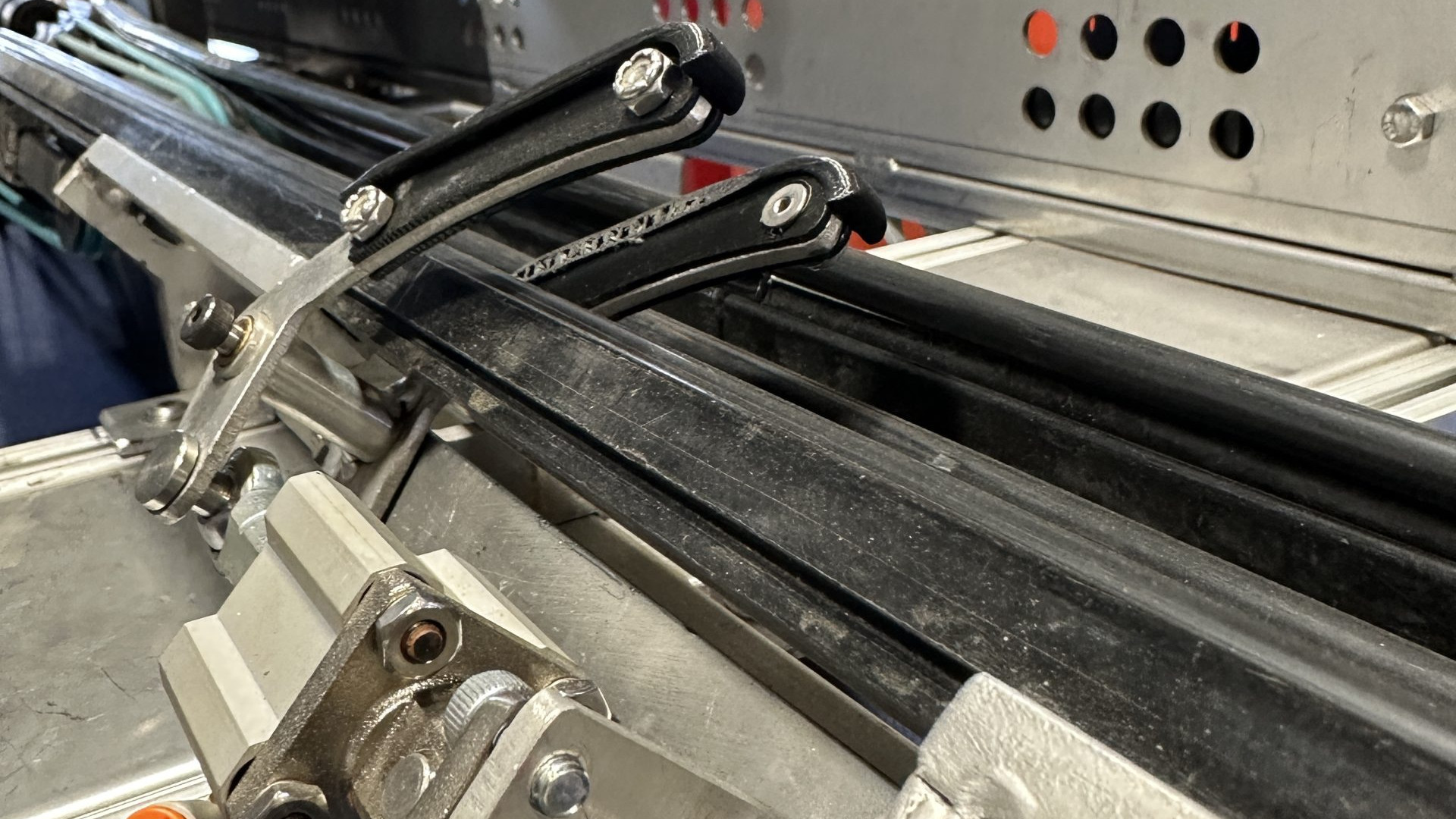

The AccuVision 360 sorter is a revolutionary way to sort potatoes, sweet potatoes or other oblong-shaped products. We’ve combined a new presentation system with an updated 4-cable transport system. Paired with our ID Technology AI-powered sorting capabilities, the AccuVision 360 offfers you a high capacity, high speed sorter that blows away the competition in performance and price.

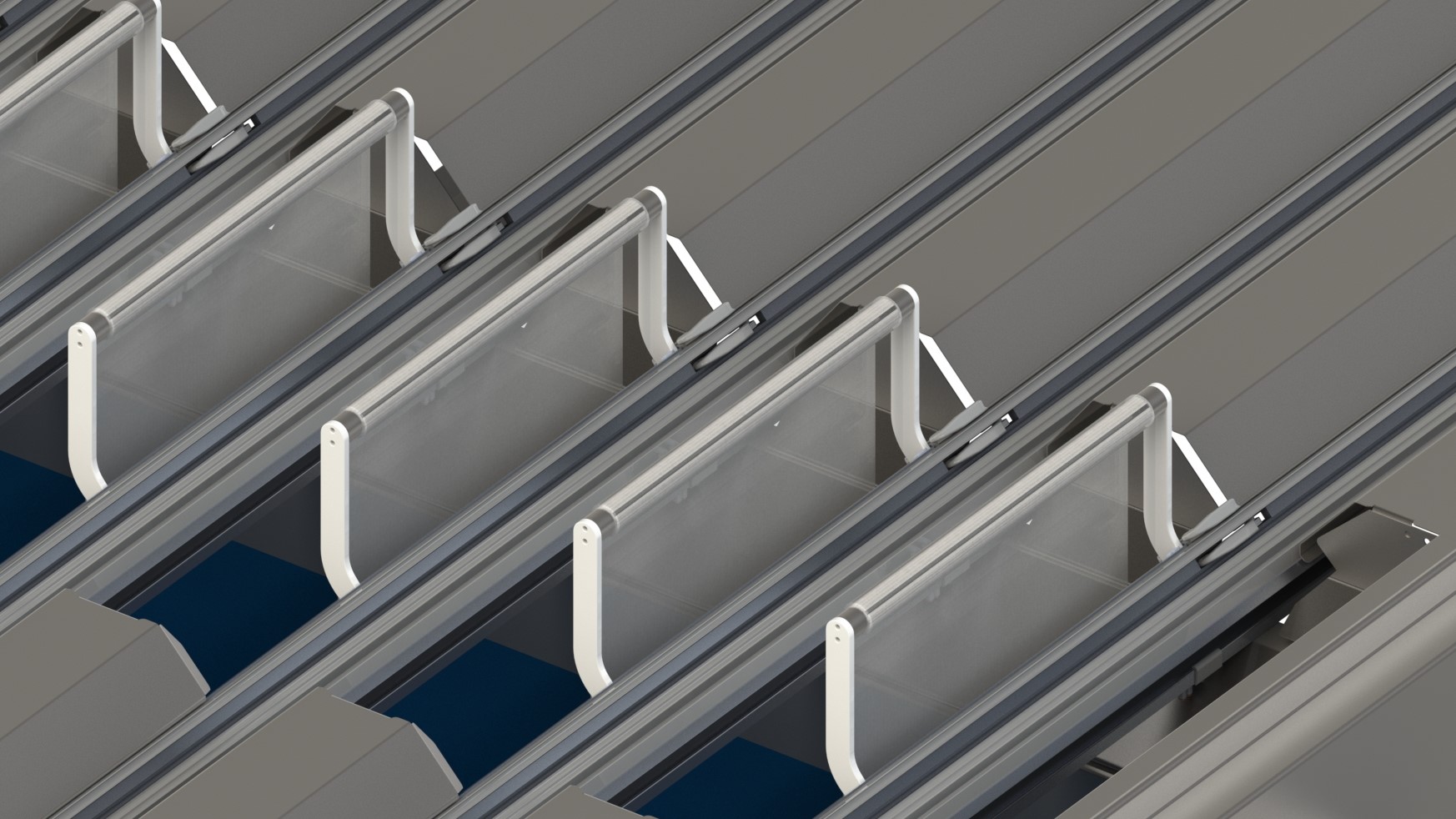

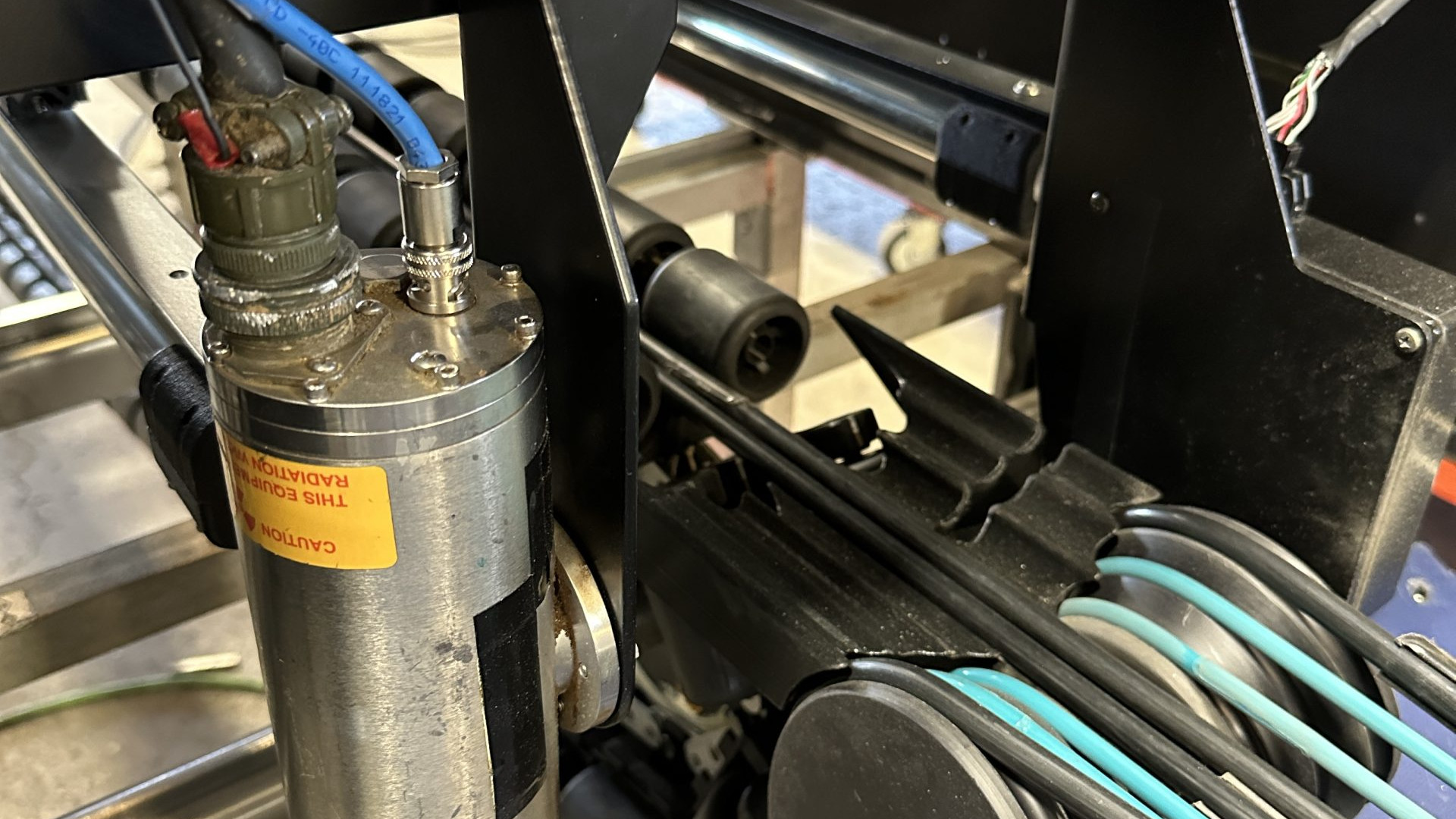

Each piece of product running through the AccuVision 360 is rotated as it passes under our high-definition, multispectral camera — 1 per lane with 2 mirrors mounted at opposing 45-degree angles and custom-tuned LED lighting. The resulting images show the entirety of each piece of product in ultra-high definition. Better imagery means better results: the ID Technology algorithms use the stunningly clear images to instantly make accurate sorting decisions by comparing your product to its vast data library. What’s more, the AccuVision 360 can do this at speeds no other machine can touch: up to 300 feet a minute. That’s significantly faster than any comparable machine.

ID Technology is also flexible enough to sort three or more categories, across all lanes of your AccuVision 360. Adjusting your parameters is easy using ID Technology intuitive controls and easy-to-use user interface (UI). Live imagery shows you exactly how your changes will affect the product you’re sorting — in real time.

Like all our products, the AccuVision 360 is a robust machine. It uses a dual-paddle ejection system that is gentle enough to protect your product, but strong enough to last. Compared to delicate, finger ejection systems, our paddles are easier to maintain, last longer and, should they ever need to be replaced, are cheaper to fix. Combined with our updated 4-cable transport system, these paddles will also yield fewer returns than ever before. That makes the AccuVision 360 a great value for your business…and one that will continue to be so, season after season. Capable of sorting at speeds up to 300 feet per minute, the AccuVision 360 leads the industry in performance for elongated produce. Its revolutionary system rotates each product under our cameras for complete 360° visibility of each piece of product. Images are captured in ultra-high-resolution by a dedicated multispectral camera per lane. This allows for up to 30 classifications per lane, based on shape, size, surface quality, weight or other customer-designated criteria. With optional x-ray integration for internal defect detection and a robust but gentle paddle ejection system that protects delicate product, the AccuVision 360 delivers consistent, gentle handling. Built from durable stainless steel with a modern 4-cable transport setup, it’s a powerhouse that’s easy to maintain and built to last—making it a smart choice for forward-thinking fresh produce operations.

- Available in configurations from 1 to 12 transport lanes

- High volume: accurate sorting at up to 300 feet per minute, making it the fastest machine of its type on the market

- Capable of 30 or more separate classifications, per lane

- Revolutionary presentation system, spinning each piece of product for complete, high-quality imagery

- ID Technology package, with custom-tuned lighting in visible and infrared spectrum and high-definition, and ultra-high-resolution camera

- Super-accurate, AI-powered sorting by defects, dimensions, shape, size, and/or weight

- Reliable, robust, and easy to maintain transport system and ejector paddles

- Can be equipped with x-ray capabilities for internal crop analysis to detect hollow heart, cell granulation and other internal defects

- Easily paired with AccuFill and AccuCount carton filling systems

- Fast: 300 feet per second speeds…significantly faster than the competition

- Available from 1 to 12 transport lanes

- Customizable drop location, 30 or more sorts per lane

- Hollow-heart detection available

Construction

- Made in Exeter, California

- 24-month warranty

- 304 stainless steel throughout; higher grades are available

- Modular design for superior durability and easier installation

- Blue PVC belts

- Electrical components by Allen Bradley; other marks available

- Meets or exceeds all major government and retailer standards

The AccuVision 360 is engineered for high-speed sorting of oblong-shaped produce using full 360-degree product rotation and ultra-HD imaging. With AI-powered accuracy, it delivers unmatched grading consistency at speeds up to 300 feet per minute. Whether upgrading your line or expanding capacity, AccuVision 360 ensures your operation runs smarter and faster. Contact us to learn how it fits into your packing workflow.